摘 要

本文旨在探讨NAF250行星减速器的设计与实现过程。行星齿轮减速器作为原动机和工作机之间的独立封闭传动装置,具有结构紧凑、体积小、重量轻、效率高、传动比大等优点,在各类工作机械中得到了广泛应用。本文首先概述了行星齿轮减速器的特点和要求, 分析了国内外行星齿轮减速器的发展现状和趋势。在此基础上,针对NAF250型号,本文详细设计了其总体结构方案,包括齿轮传动设计、重要零部件的选型与强度校核等关键内容。

在设计过程中,本文依据给定的原始数据(传动比为5.4,输出扭矩为360N.m,输入转速为640rpm,过载系数为1.5,传动效率为0.97),参考了多本权威著作和标准,如《行星齿轮传动设计》、《减速器设计实例精解》以及JB-T6502-2009 NAF行星齿轮减速器标准等。通过详细的理论计算与分析,本文完成了NAF250行星减速器的零件设计、整体装配设计,并初步确定了其总体结构设计方案。

本文的研究成果不仅为NAF250行星减速器的进一步研制和发展提供了理论依据,同时也为其他型号行星减速器的设计和生产提供了有益的参考。通过本文的研究,我们可以更好地理解行星齿轮传动的工作原理和性能特点,为行星齿轮减速器产品的开发和性能评价提供科学依据。

关键词:NAF250行星减速器;行星齿轮传动;设计;总体结构;强度校核

Abstract

This paper aims to explore the design and implementation process of the NAF250 planetary reducer. As an independent closed transmission device between mover and working machine, planetary gear reducer has the advantages of compact structure, small volume, light weight, high efficiency and large transmission ratio, and has been widely used in all kinds of working machinery. This paper first summarizes the characteristics and requirements of planetary gear reducer, and analyzes the development status and trend of planetary gear reducer at home and abroad. On this basis, for the NAF250 model, this paper designs the overall structure scheme in detail, including gear transmission design, important component selection and strength check and other key contents.

In the design process, this paper is based on the given raw data (transmission ratio of 5.4, output torque of 360N.m, input speed of 640rpm, overload coefficient of 1.5, transmission efficiency of 0.97), refers to many authoritative works and standards, such as "planetary gear transmission design", "Precision examples of reducer design" and JB-T6502-2009 NAF planetary gear reducer standard, etc. Through detailed theoretical calculation and analysis, this paper completes the part design and overall assembly design of NAF250 planetary reducer, and preliminarily determines the overall structure design scheme.

The results of this paper not only provide a theoretical basis for the further development and development of NAF250 planetary reducer, but also provide a useful reference for the design and production of other models of planetary reducer. Through the research of this paper, we can better understand the working principle and performance characteristics of planetary gear transmission, and provide a scientific basis for the development and performance evaluation of planetary gear reducer products.

Key words: NAF250 planetary reducer; planetary gear drive; design; overall structure; strength check

目录

NAF250行星减速器设计及仿真摘要 XIII

前言 2

1 行星减速器的概述 3

1.1 术语及定义 3

1.1.1 轮系 3

1.2 周转轮系的组成 3

1.2 行星齿轮的传动类型 3

1.3 行星齿轮的特点 4

2 总体方案设计 5

2.1 毕业设计所需资料及原始数据(指导教师选定部分) 5

2.2 基本参数 5

3 齿轮材料、热处理工艺及制造工艺的选定 7

4 齿轮传动设计 7

4.1 行星齿轮的配齿计算 7

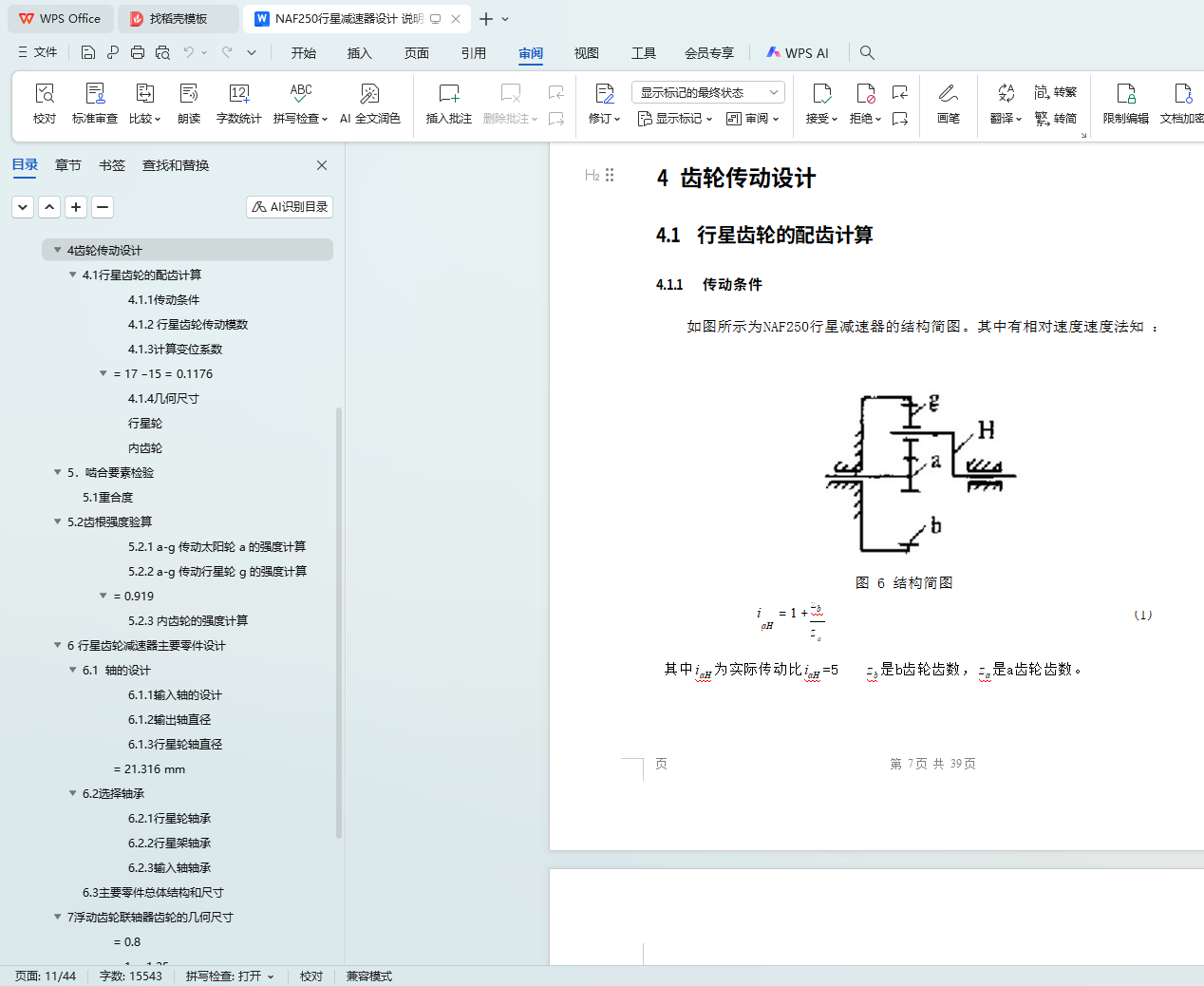

4.1.1 传动条件 7

4.1.2 行星齿轮传动模数 9

4.1.3 计算变位系数 11

4.1.4 几何尺寸 11

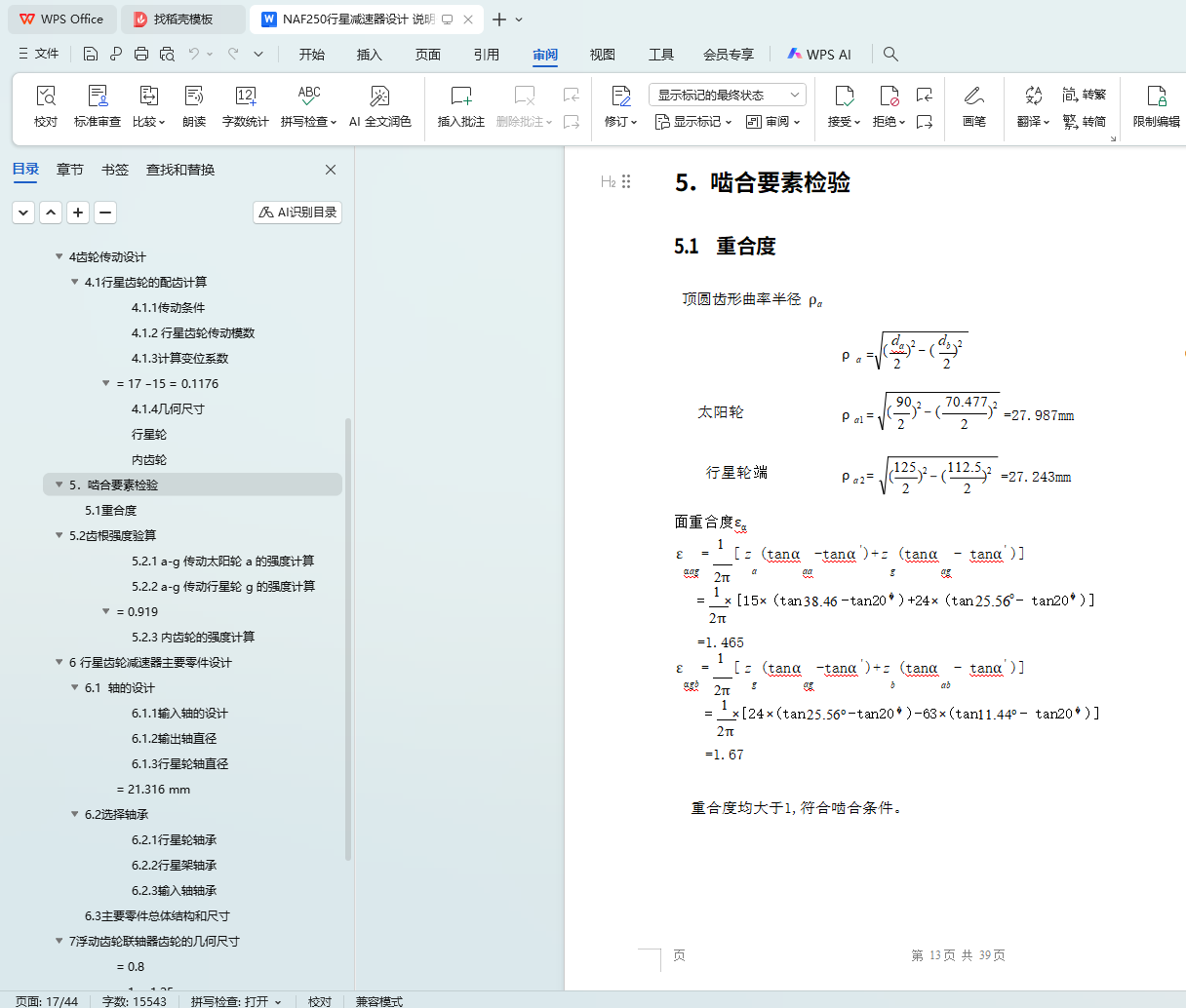

5.啮合要素检验 13

5.1 重合度 13

5.2 齿根强度验算 14

5.2.1 a-g 传动太阳轮 a 的强度计算 14

5.2.2 a-g 传动行星轮 g 的强度计算 17

5.2.3 内齿轮的强度计算 21

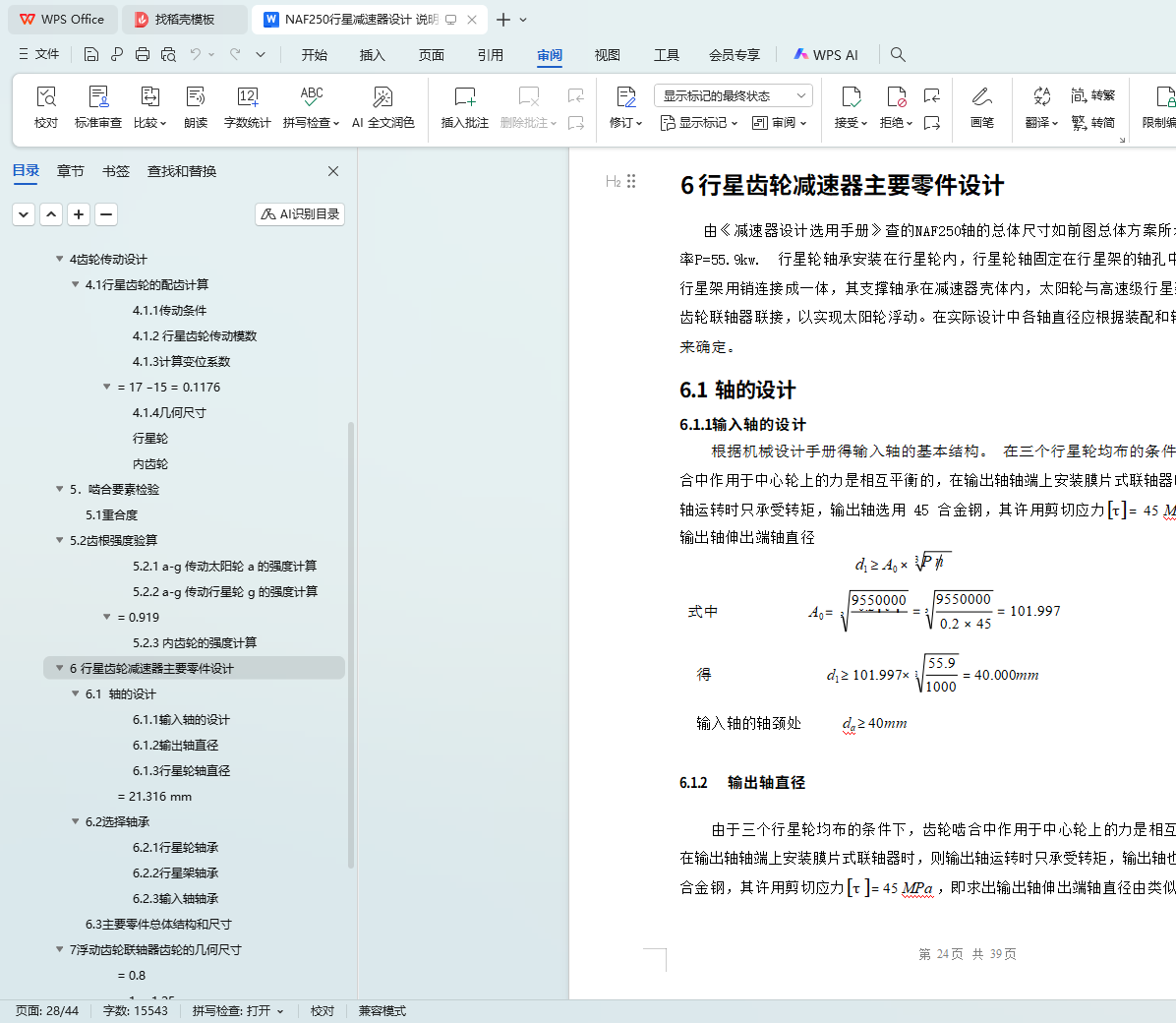

6 行星齿轮减速器主要零件设计 24

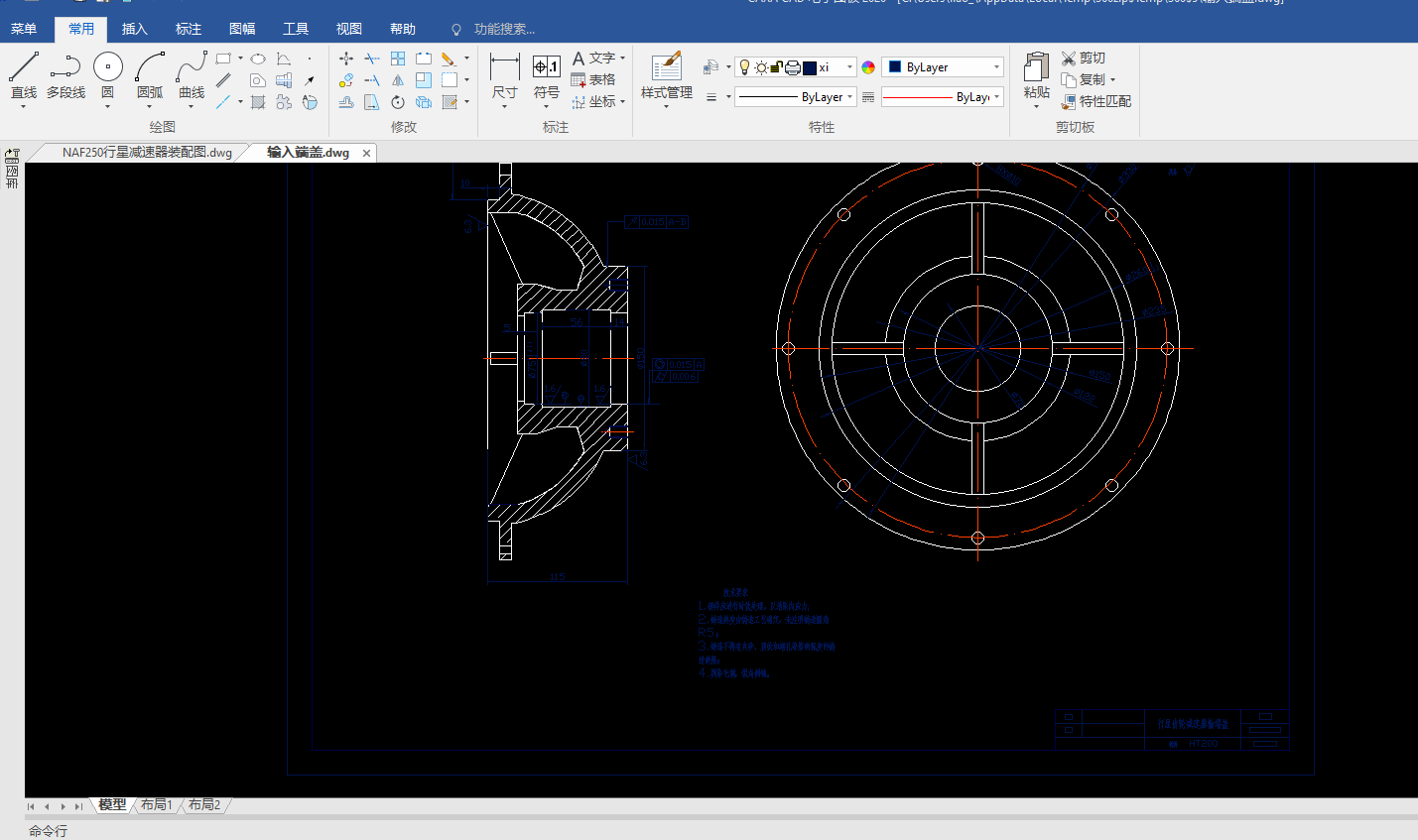

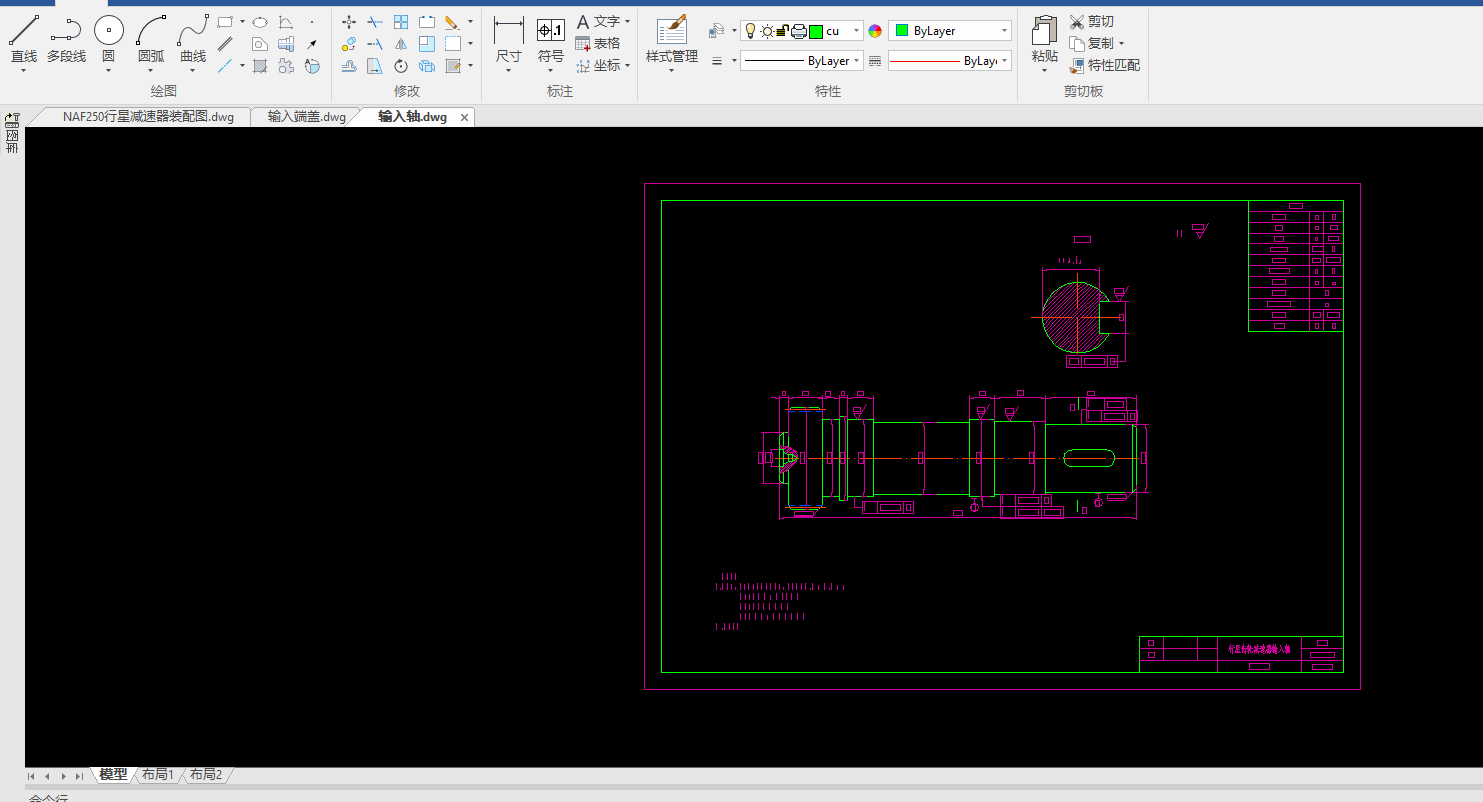

6.1 轴的设计 24

6.1.1 输入轴的设计 24

6.1.2 输出轴直径 24

6.1.3 行星轮轴直径 25

6.2 选择轴承 25

6.2.1 行星轮轴承 25

6.2.2 输出轴轴承 26

6.2.3 输入轴轴承 26

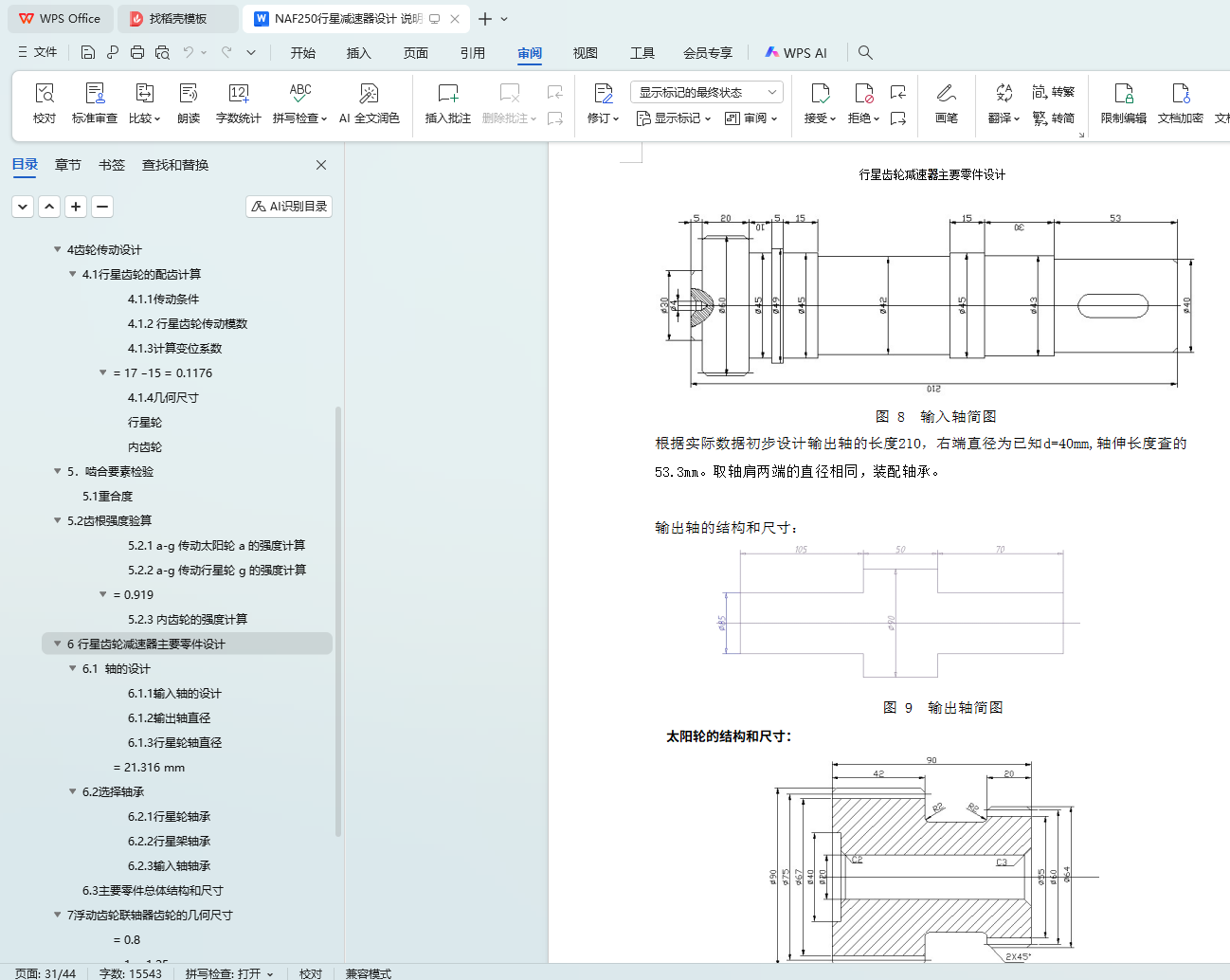

6.3 主要零件总体结构和尺寸 26

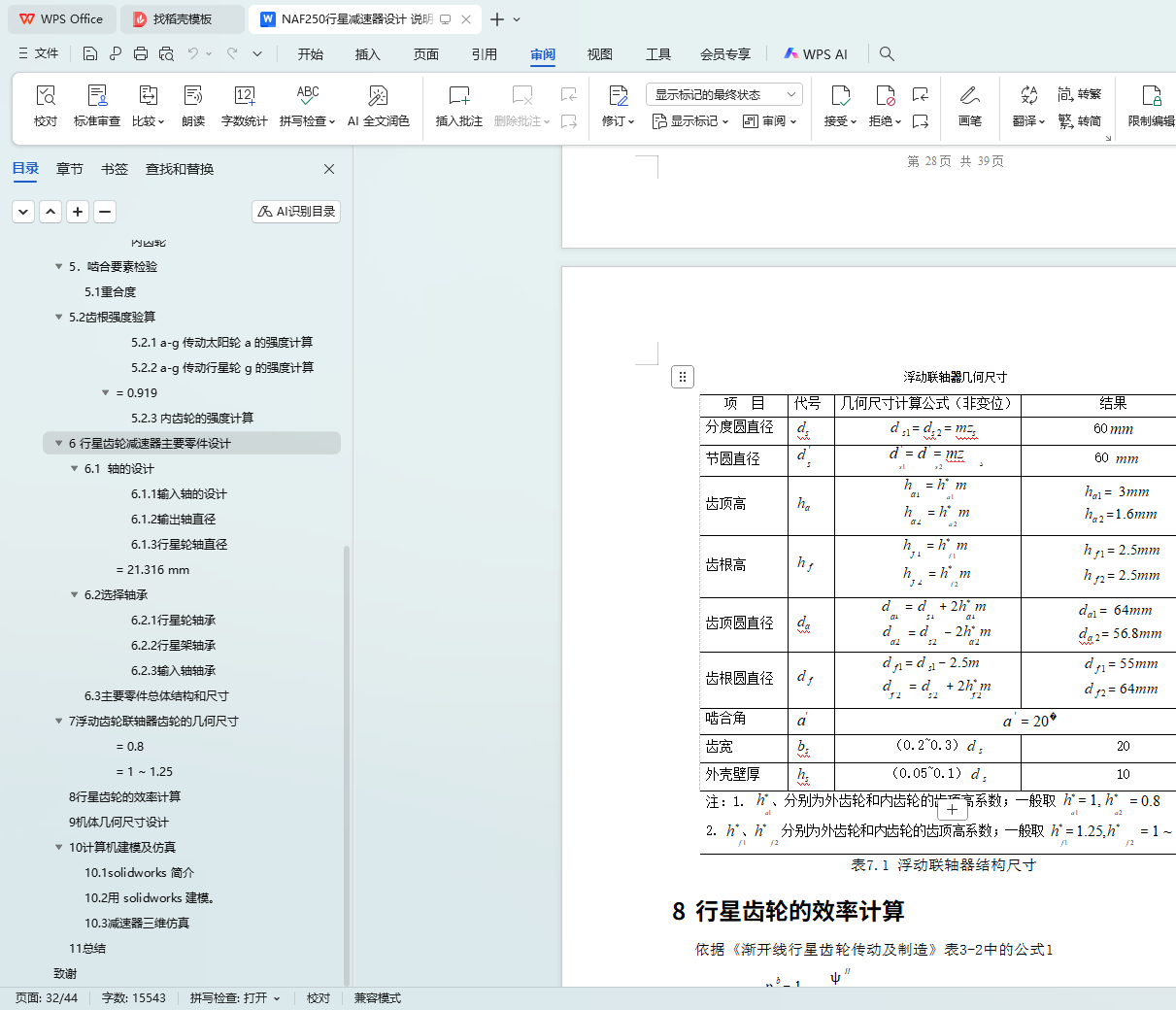

7 浮动齿轮联轴器齿轮的几何尺寸 28

8 行星齿轮的效率计算 29

9 机体几何尺寸设计 30

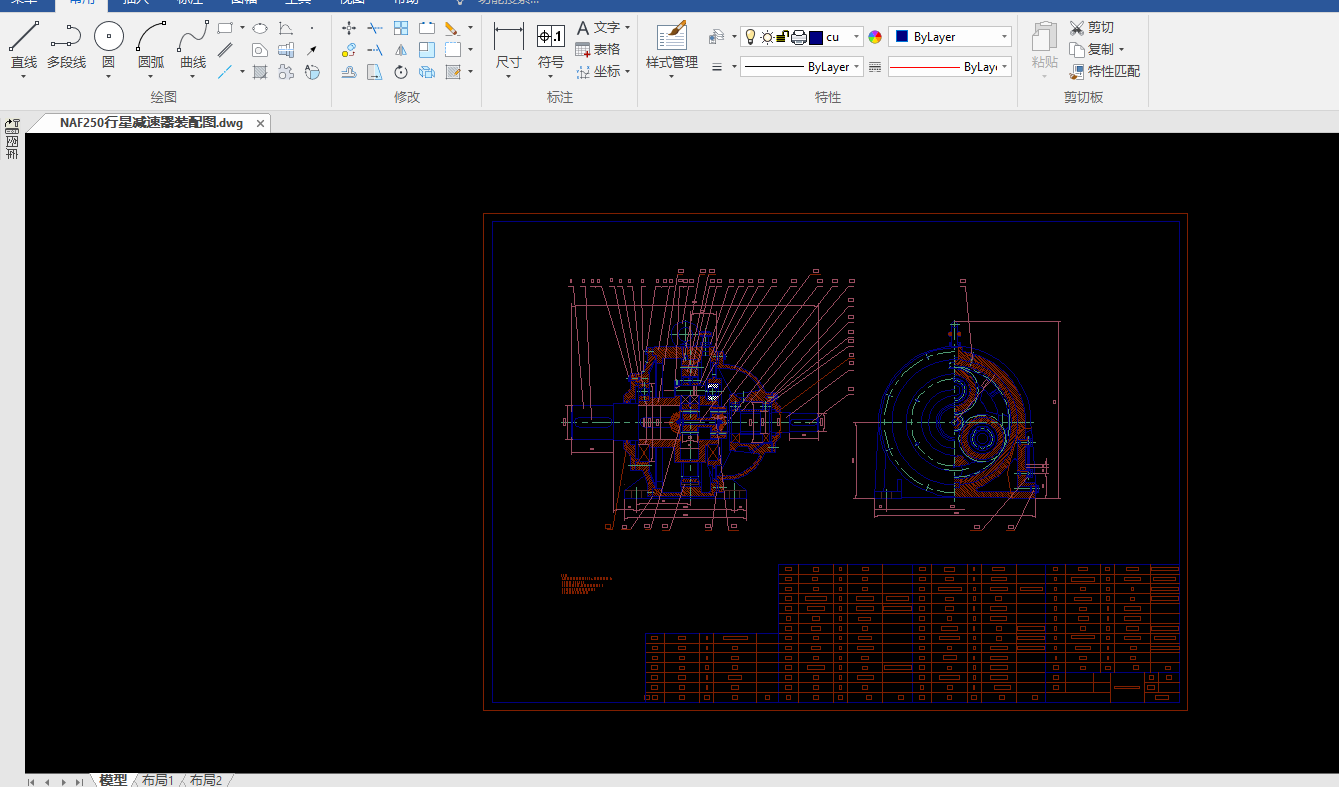

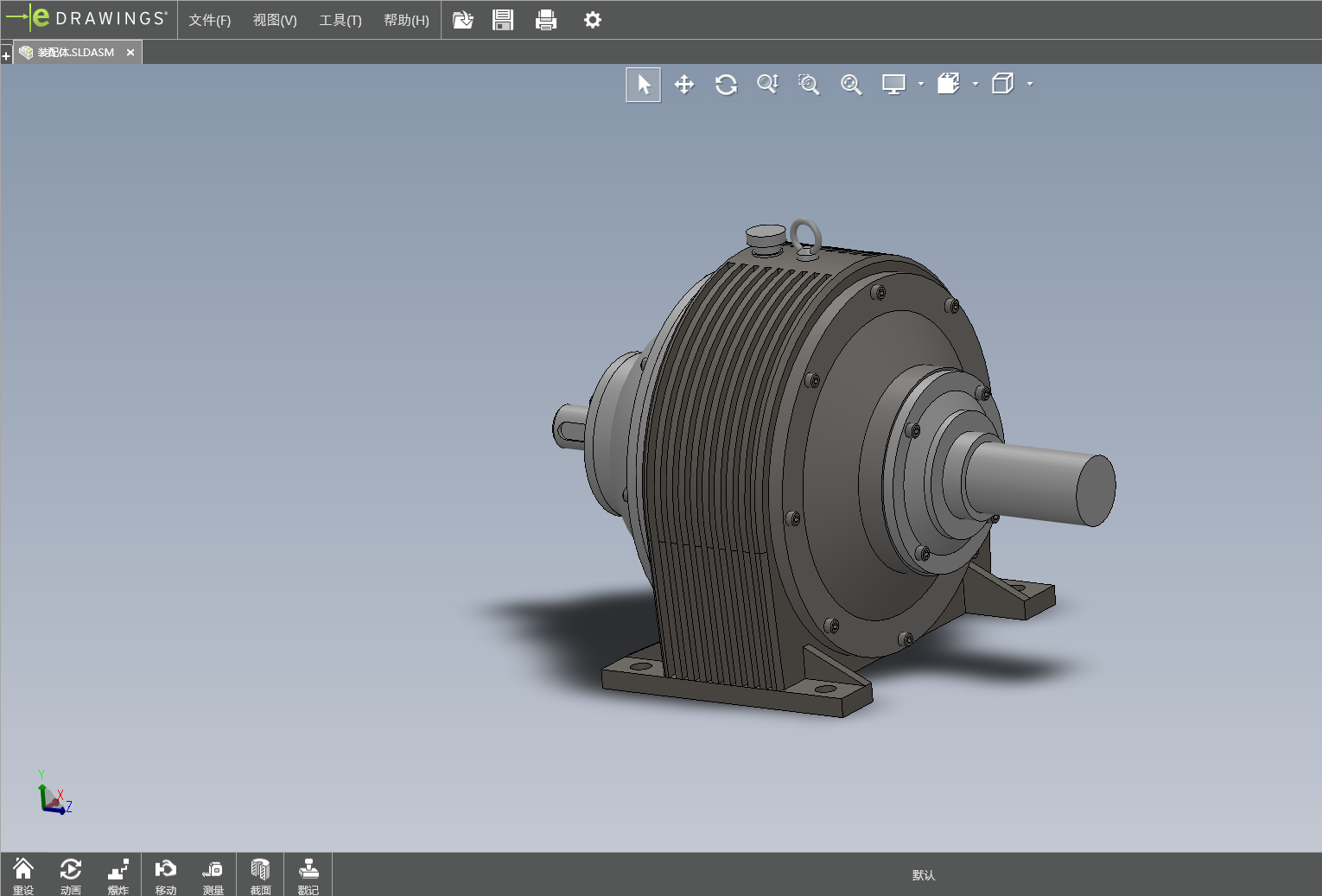

10 计算机建模及仿真 30

10.1 solidworks 简介 30

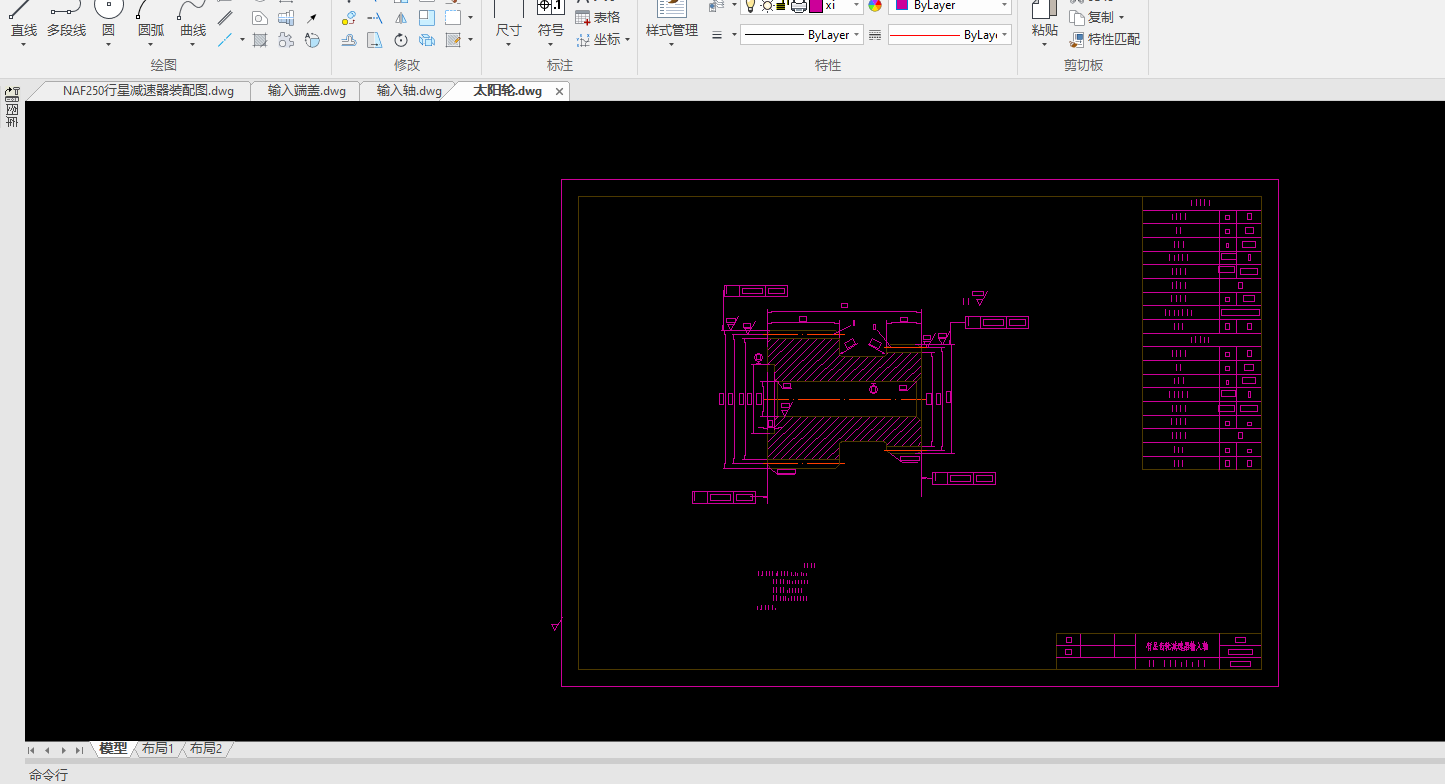

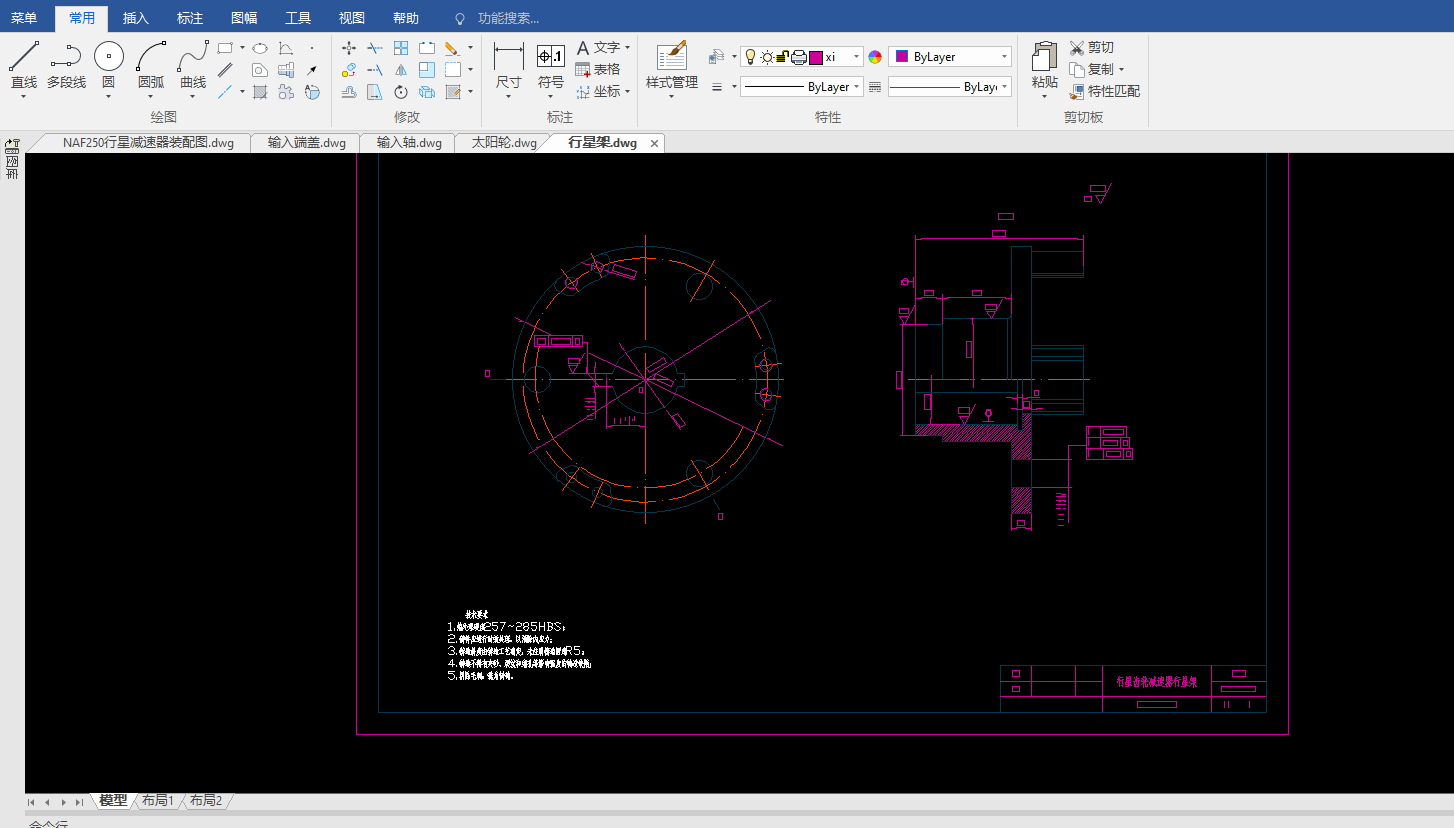

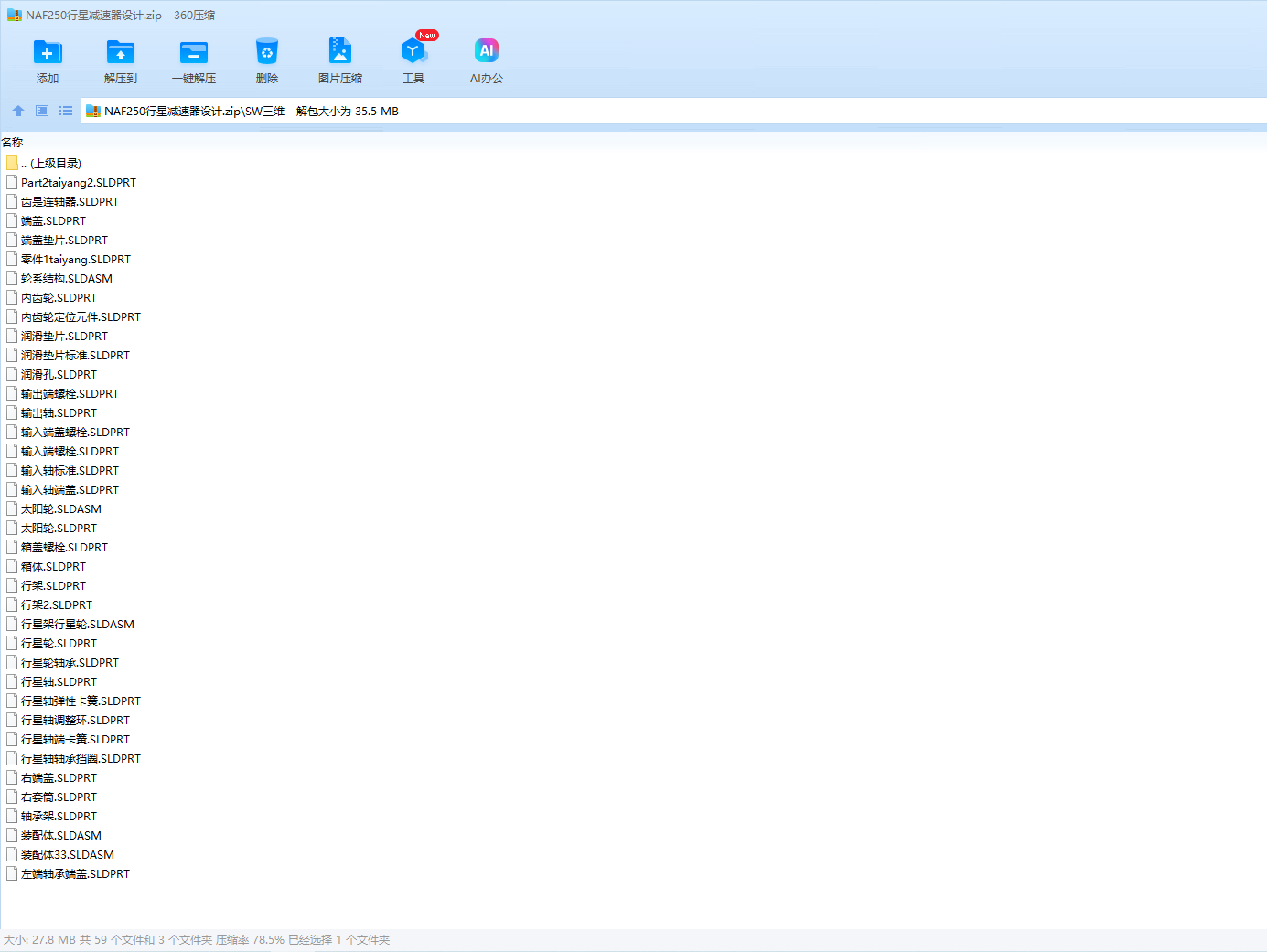

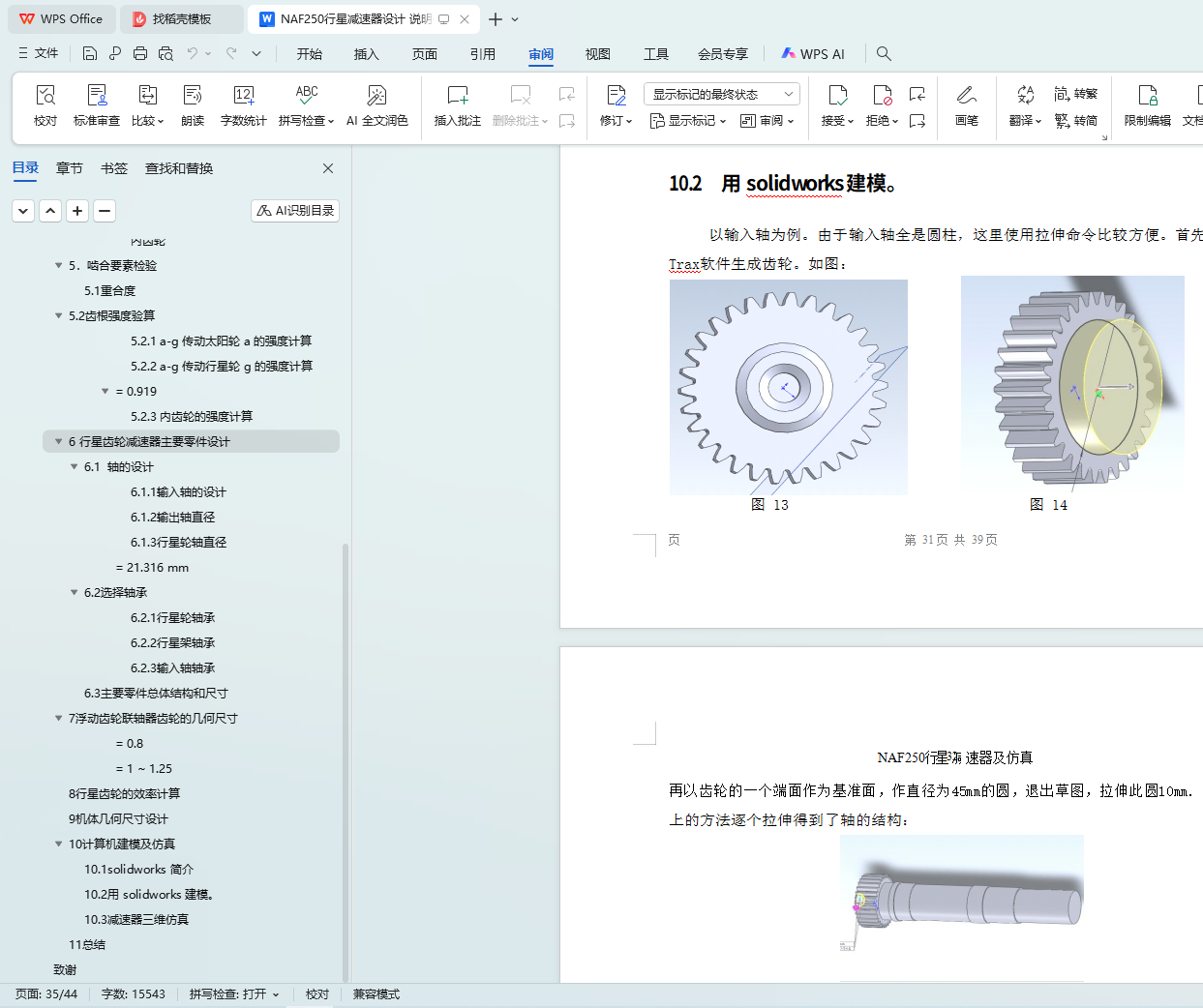

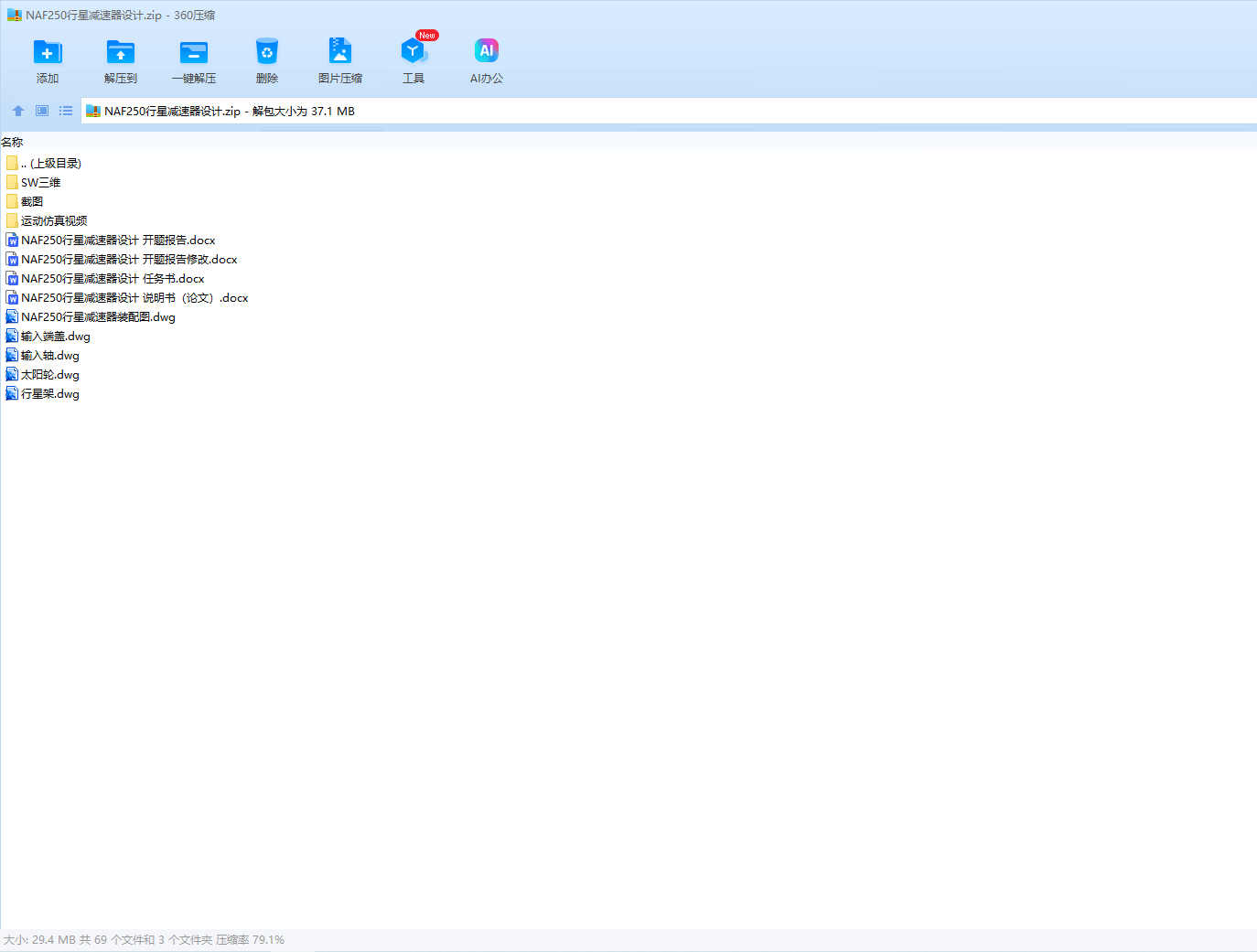

10.2 用 solidworks 建模。 31

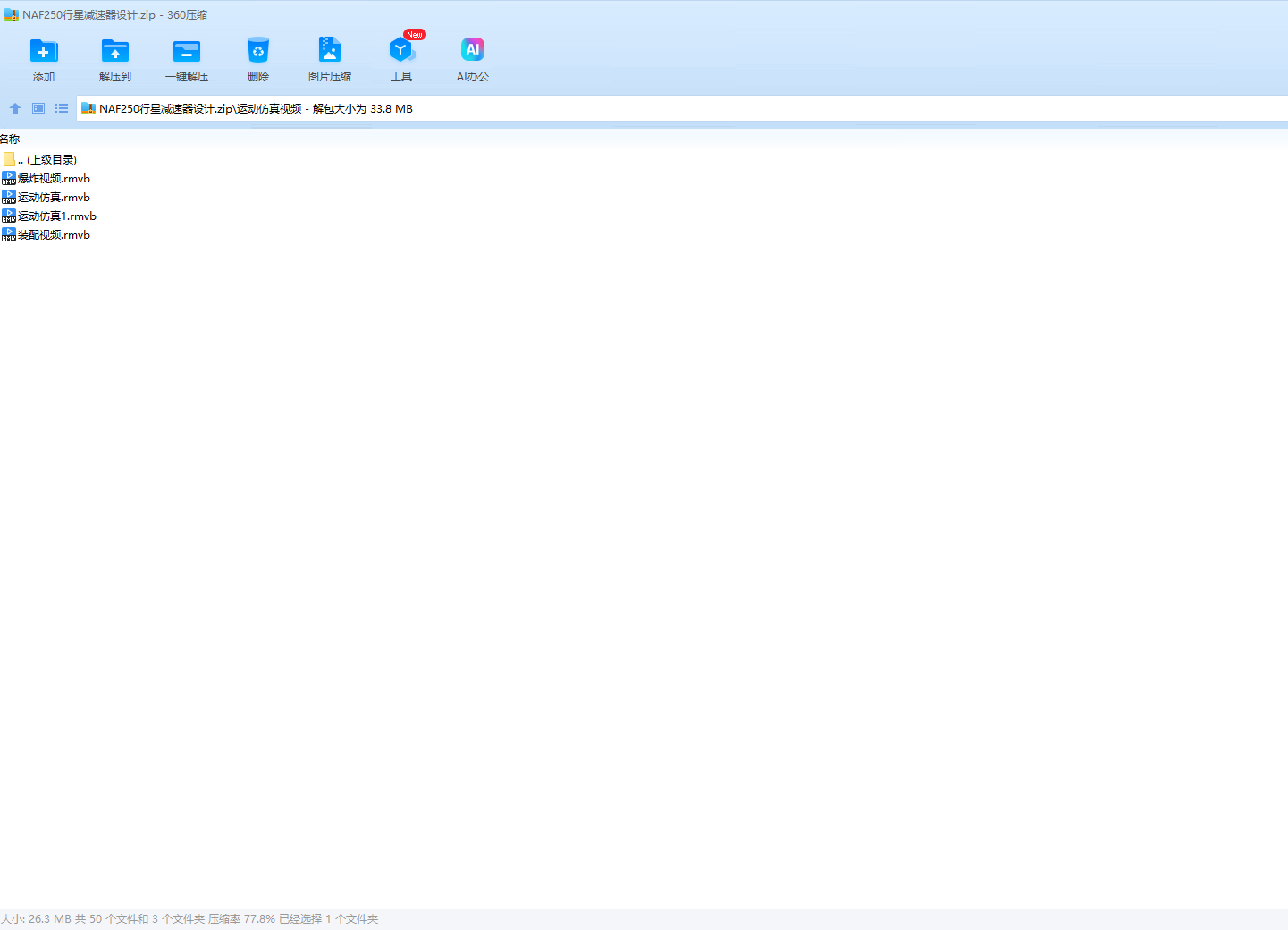

10.3 减速器三维仿真 35

11 总结 37

12 参考文献 38

13 致谢 39