摘 要

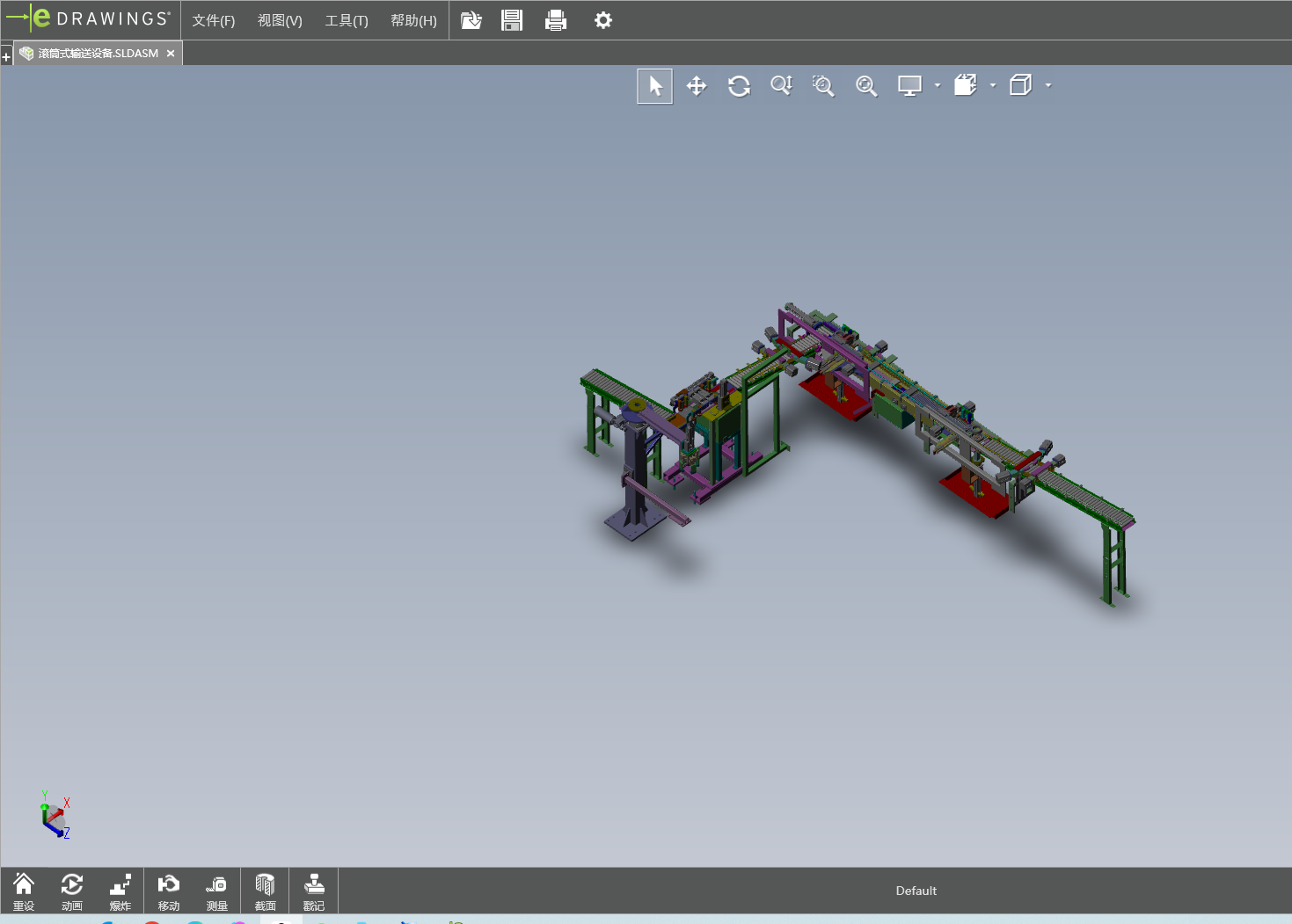

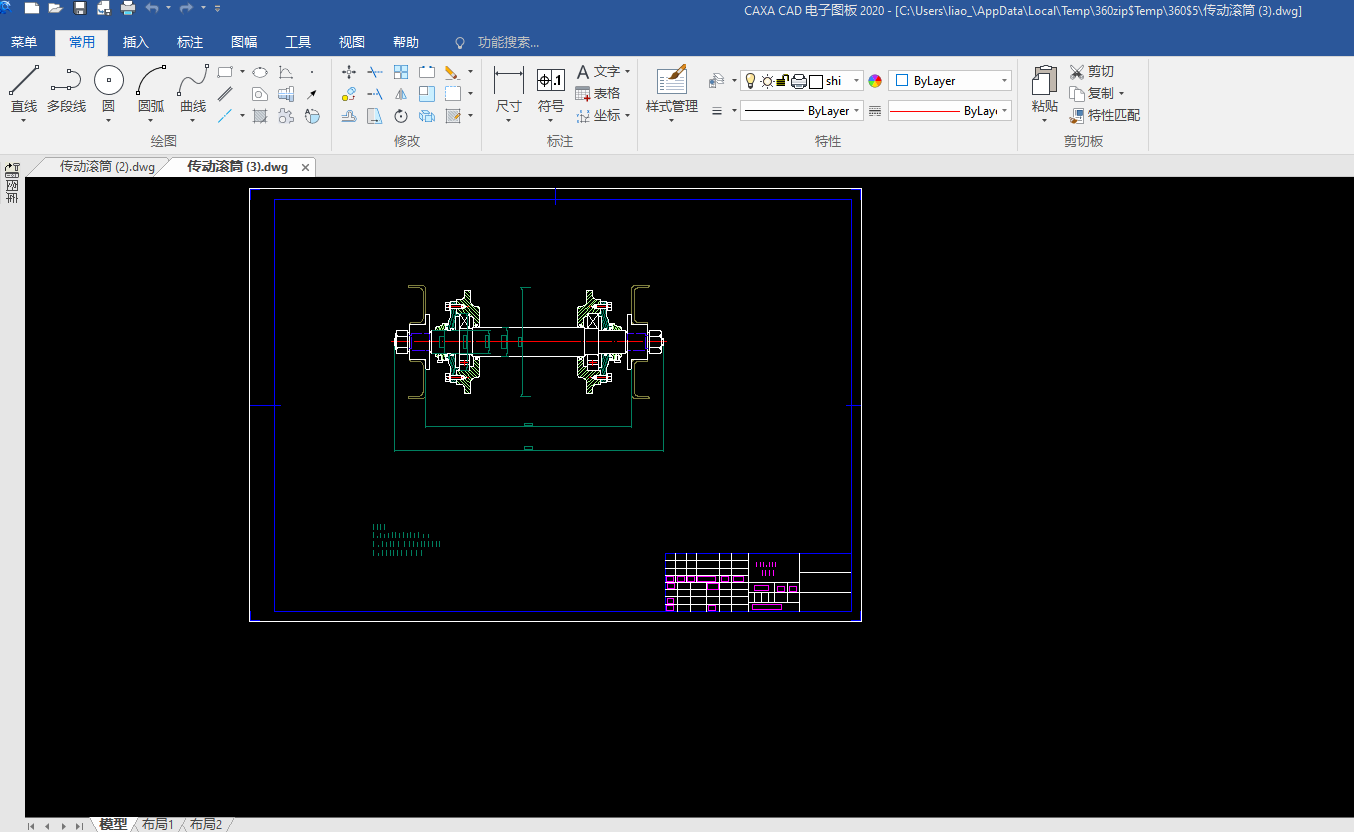

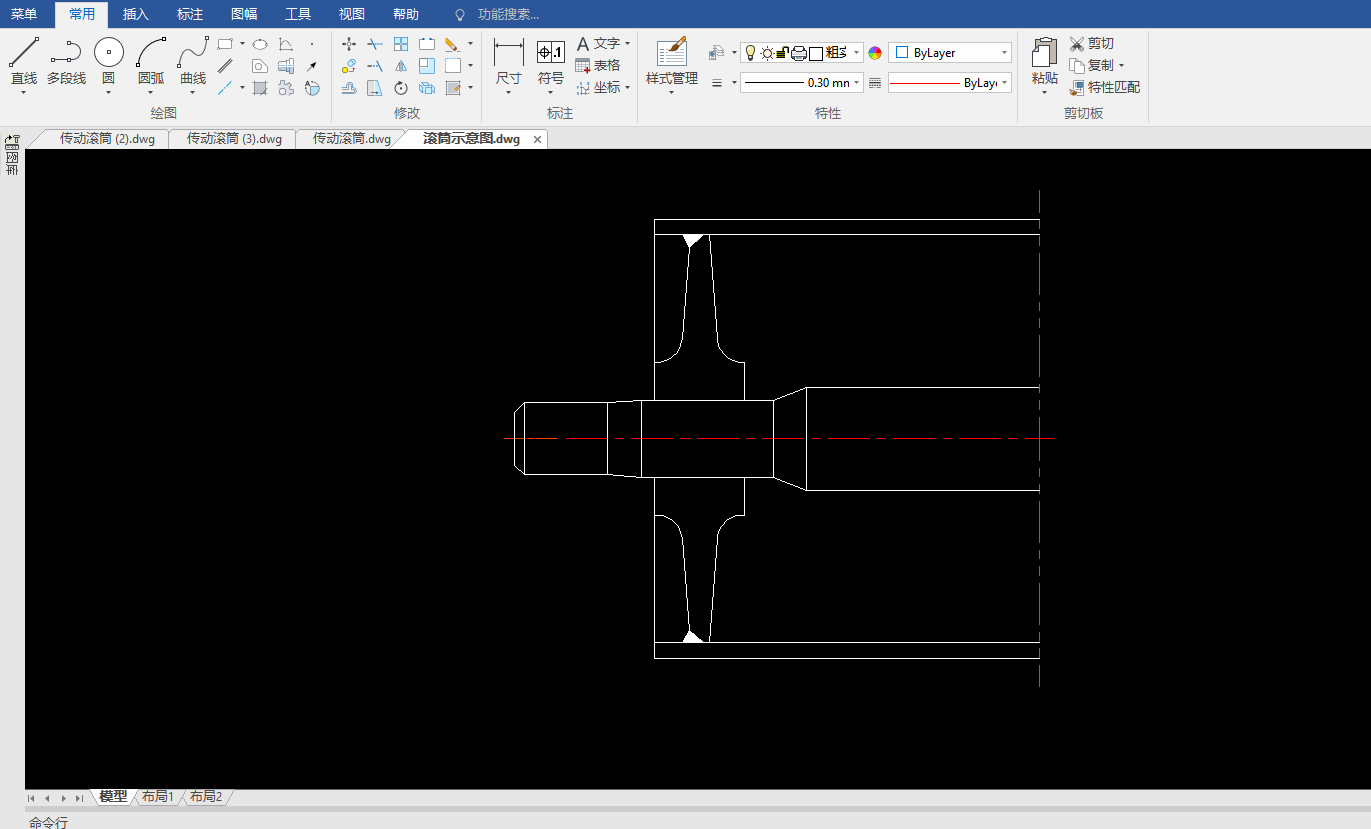

本文针对当前大型滚筒设计研究方法相对滞后的现状,深入开展了滚筒式输送设备的力学分析及设计研究。随着全球制造业向自动化、智能化方向发展,滚筒式输送设备作为物流系统和生产线的重要组成部分,其性能的优化对于提升生产效率、降低成本具有重要意义。本研究首先分析了滚筒式输送设备的受力状况,明确了其表面载荷沿轴向和周向的分布规律。在此基础上,根据设计侧重点的不同对滚筒式输送设备进行了分类,并对比了国内外各类滚筒式输送设备的设计方法,提炼出筒体、辐板、轮毂及滚筒轴的详细结构设计方案。为进一步验证设计的合理性,本文还进行了滚筒式输送设备的参数化建模和有限元分析,通过模拟仿真得出了各零部件的应力和变形情况,为滚筒结构的优化设计提供了重要的理论依据。本研究不仅有助于提升滚筒式输送设备的技术水平,还可为物流、制造等行业的自动化生产提供有力支持。

关键词:滚筒式输送设备;力学分析;结构设计;参数化建模;有限元分析

Abstract

Belt-conveyor system is the most important transport equipment which can carry

This paper discusses the mechanical analysis and design of large drum conveying equipment. With the development of global manufacturing industry to the direction of automation and intelligence, as an important part of logistics system and production line, the optimization of its performance is of great significance for improving production efficiency and reducing cost. In this study, the force of roller conveying equipment was first analyzed and the distribution of surface load along axial and circumferential direction was defined. On this basis, the drum conveying equipment is classified according to the different design focus, and then the design methods of various kinds of drum conveying equipment at home and abroad are compared, and the detailed structure design scheme of cylinder, spoke plate, wheel hub and drum shaft is extracted. In order to further verify the rationality of the design, this paper also conducts the parametric modeling and finite element analysis of the drum-type conveying equipment, and the stress and deformation of each component are obtained through simulation, which provides an important theoretical basis for the optimization design of the drum structure. This study can not only help to improve the technical level of the drum conveying equipment, but also can provide strong support for the automatic production of logistics, manufacturing and other industries.

Key words: drum conveying equipment; mechanical analysis; structural design; parametric modeling; finite element analysis

目录

摘 要

Abstract

第一章 绪 论

1.1 概述

1.2 滚筒式输送设备的研究目的和意义

1.3 国内外研究现状

1.4 本文研究的主要内容

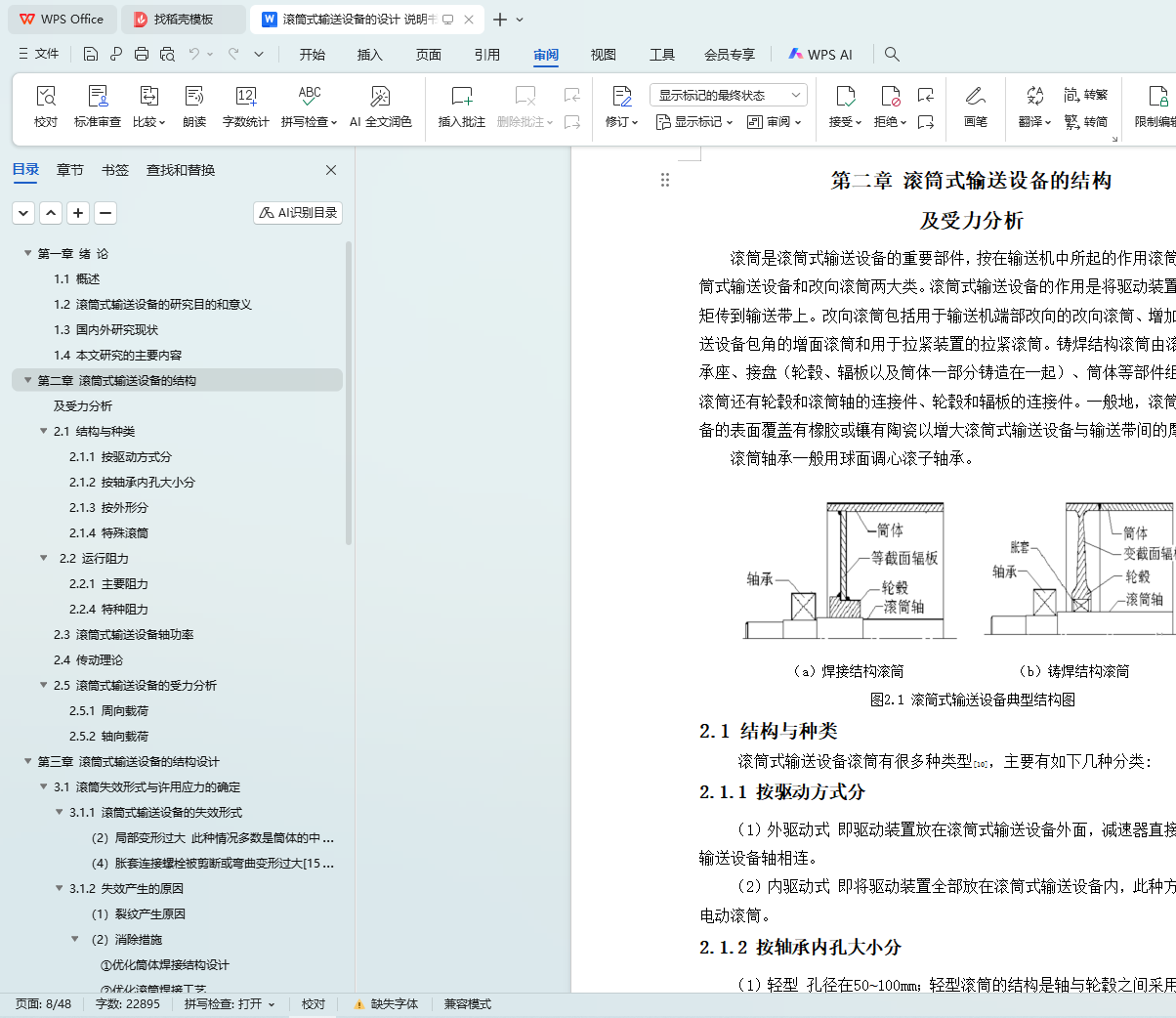

第二章 滚筒式输送设备的结构

及受力分析

2.1 结构与种类

2.2 运行阻力

2.3 滚筒式输送设备轴功率

2.4 传动理论

2.5 滚筒式输送设备的受力分析

第三章 滚筒式输送设备的结构设计

3.1 滚筒失效形式与许用应力的确定

3.1.1 滚筒式输送设备的失效形式

3.1.2 失效产生的原因

3.1.3 滚筒许用应力的确定

3.2 滚筒式输送设备结构设计

3.2.1 滚筒式输送设备最小直径的确定

3.2.2 筒体的厚度

3.2.3 滚筒式输送设备轴直径的计算

3.2.4 辐板厚度的确定

3.2.5 滚筒轴与辐板间的力矩分配

3.2.6 轮毂尺寸的确定

3.2.7 铸焊滚筒接盘与中间筒体焊缝位置的确定

3.2.8 胀套的计算

第四章 滚筒式输送设备有限元模型的建立与分析

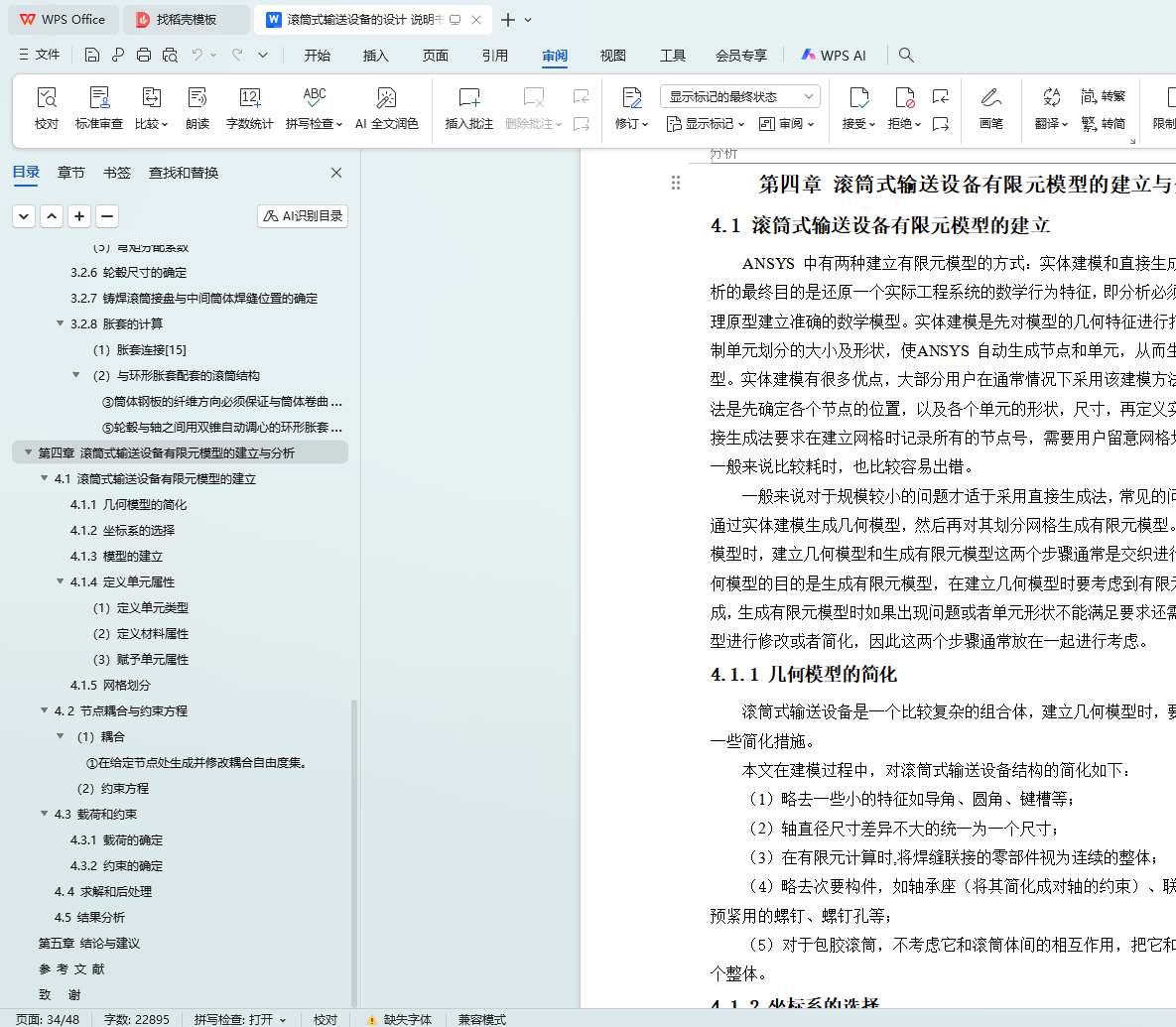

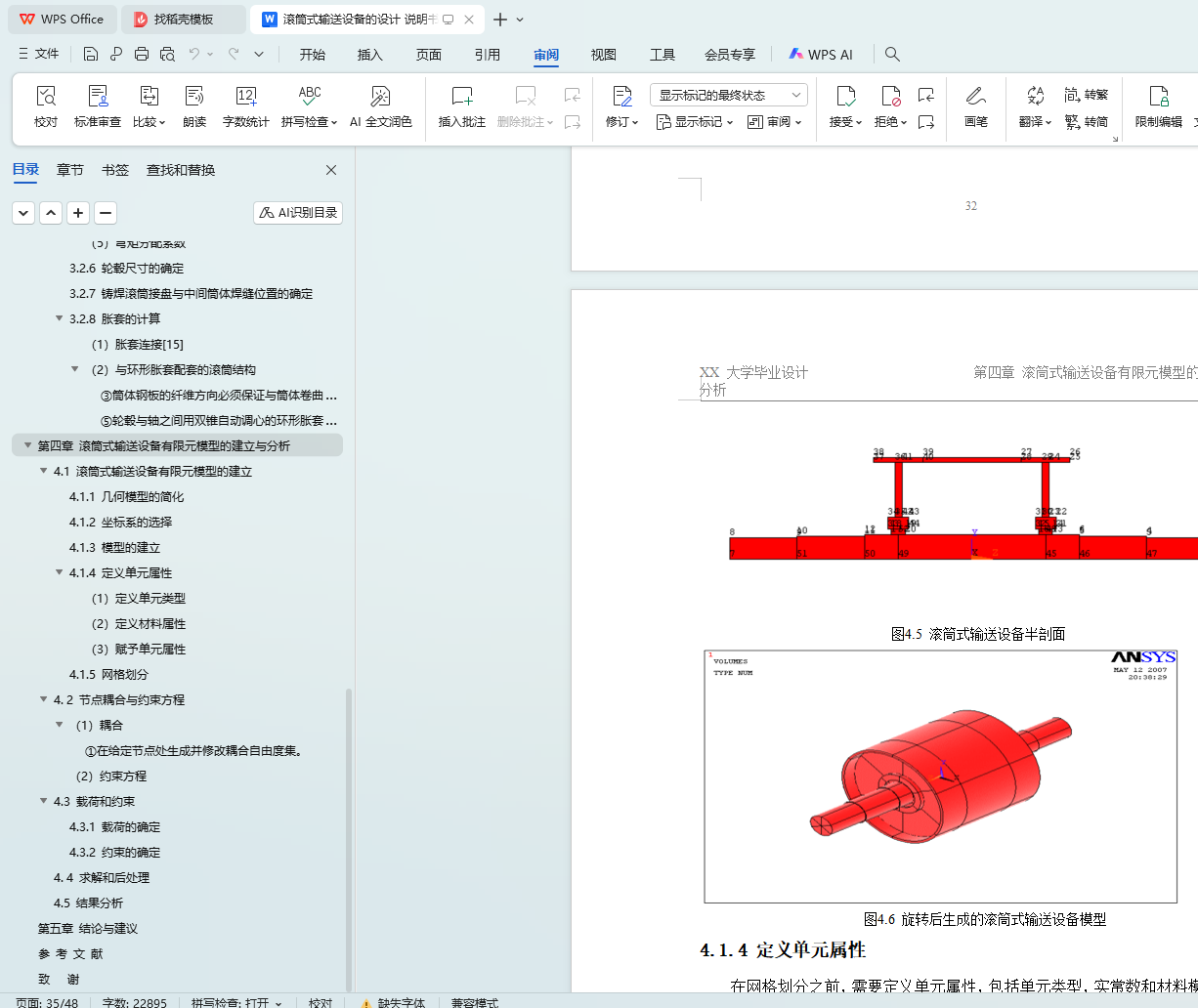

4.1 滚筒式输送设备有限元模型的建立

第五章 结论与建议

参 考 文 献

致 谢