摘要

核桃作为一种高营养价值的果品,在国内外市场上享有广泛的认可和需求。我国作为核桃生产大国,核桃产业具有显著的地方优势和特色,尤其在新疆等地,核桃种植面积广泛,成为当地林果业生产发展的重点。然而,核桃加工过程中存在着去外皮困难、取仁效率低以及外皮清理与分级技术落后等问题,这严重影响了核桃加工的品质和成本效益。

为了解决核桃加工过程中的这些难题,本研究致力于设计一种核桃外皮清理与分级装置。该装置的设计旨在提高核桃外皮清理的效率和分级精度,以满足日益增长的市场需求与品质要求。通过深入研究与实践,我们期望为核桃外皮清理与分级技术的创新与优化贡献力量。

在具体设计中,我们将综合考虑动力选择、材料选择、加工精度以及环保性等因素,力求实现装置的高效、稳定和可靠运行。同时,我们还将关注整体成本控制,以推动技术的广泛应用与产业化发展。

本研究将结合国内外在核桃外皮清理与分级技术上的研究成果,借鉴先进的设计理念和方法,提出一种切实可行的解决方案。通过试验和优化,我们期望最终能够设计出一种具有自主知识产权、高效、实用的核桃外皮清理与分级装置,为核桃产业的发展做出贡献。

关键词:核桃外皮清理;分级装置;机械化;自动化;效率

Abstract

Walnut, as a kind of fruit with high nutritional value, enjoys wide recognition and demand in the domestic and foreign markets. As a walnut production country, walnut industry has significant local advantages and characteristics, especially in Xinjiang and other places, walnut planting area is extensive, become the focus of the local forestry and fruit industry production development. However, there are some problems in walnut processing, such as difficult skin removal, low kernel extraction efficiency and backward skin cleaning and grading technology, which seriously affect the quality and cost effectiveness of walnut processing.

To solve these problems in walnut processing, this study aims to design a walnut skin cleaning and grading device. The device is designed to improve the efficiency and grading accuracy of walnut skin cleaning to meet the growing market demand and quality requirements. Through in-depth research and practice, we expect to contribute to the innovation and optimization of walnut skin cleaning and grading technology.

In the specific design, we will comprehensively consider the power selection, material selection, machining accuracy and environmental protection factors, and strive to achieve the efficient, stable and reliable operation of the device. At the same time, we will also pay attention to the overall cost control to promote the wide application and industrialization of technology.

This study will combine the domestic and foreign research results in walnut skin cleaning and classification technology, draw lessons from the advanced design concepts and methods, and propose a feasible solution. Through the experiment and optimization, we expect to finally design an efficient and practical walnut skin cleaning and classification device with independent intellectual property rights, to make contributions to the development of the walnut industry.

Key words: walnut skin cleaning; grading device; mechanization; automation; efficiency

目 录

摘要

Abstract

1 绪论

1.1 课题提出的背景

1.2 课题研究的目的和意义

1.3 核桃外皮清理与分级装置械的发展

1.4 核桃外皮清理与分级装置械的研究应用现状

1.4.1 目前核桃外皮清理与分级装置采用的去外皮原理

1.4.2 新型去外皮技术

1.4.3 核桃外皮清理与分级装置械的工艺研究

1.4.4 核桃外皮清理与分级装置械存在的问题

1.5 核桃外皮清理与分级装置械研究重点

1.5.1 提高核桃外皮清理与分级装置械的通用性和适应性

1.6.2 提高机械去外皮率。降低破损率

1.7.3 向自动控制和自动化方向发展

1.6 核桃外皮清理与分级装置械应用前景展望

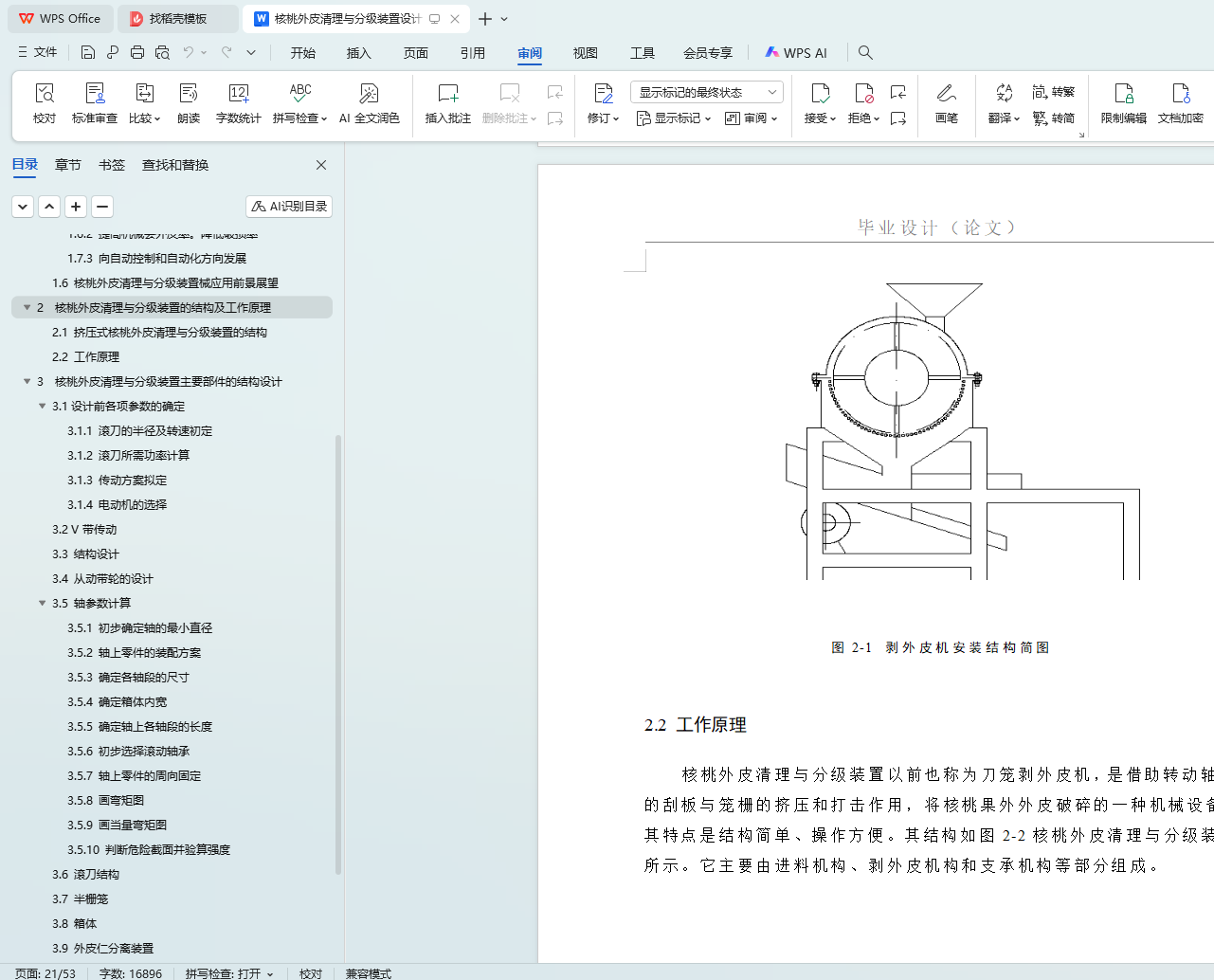

2 核桃外皮清理与分级装置的结构及工作原理

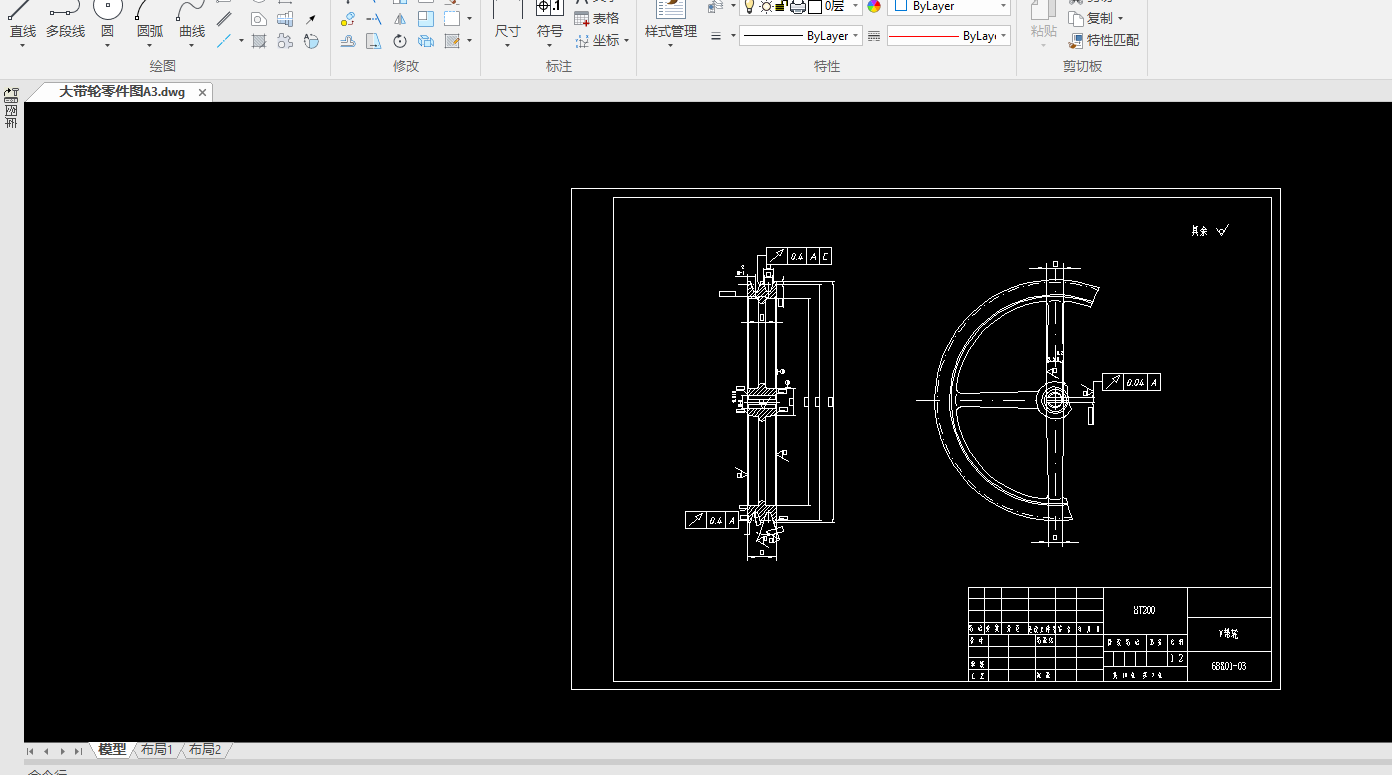

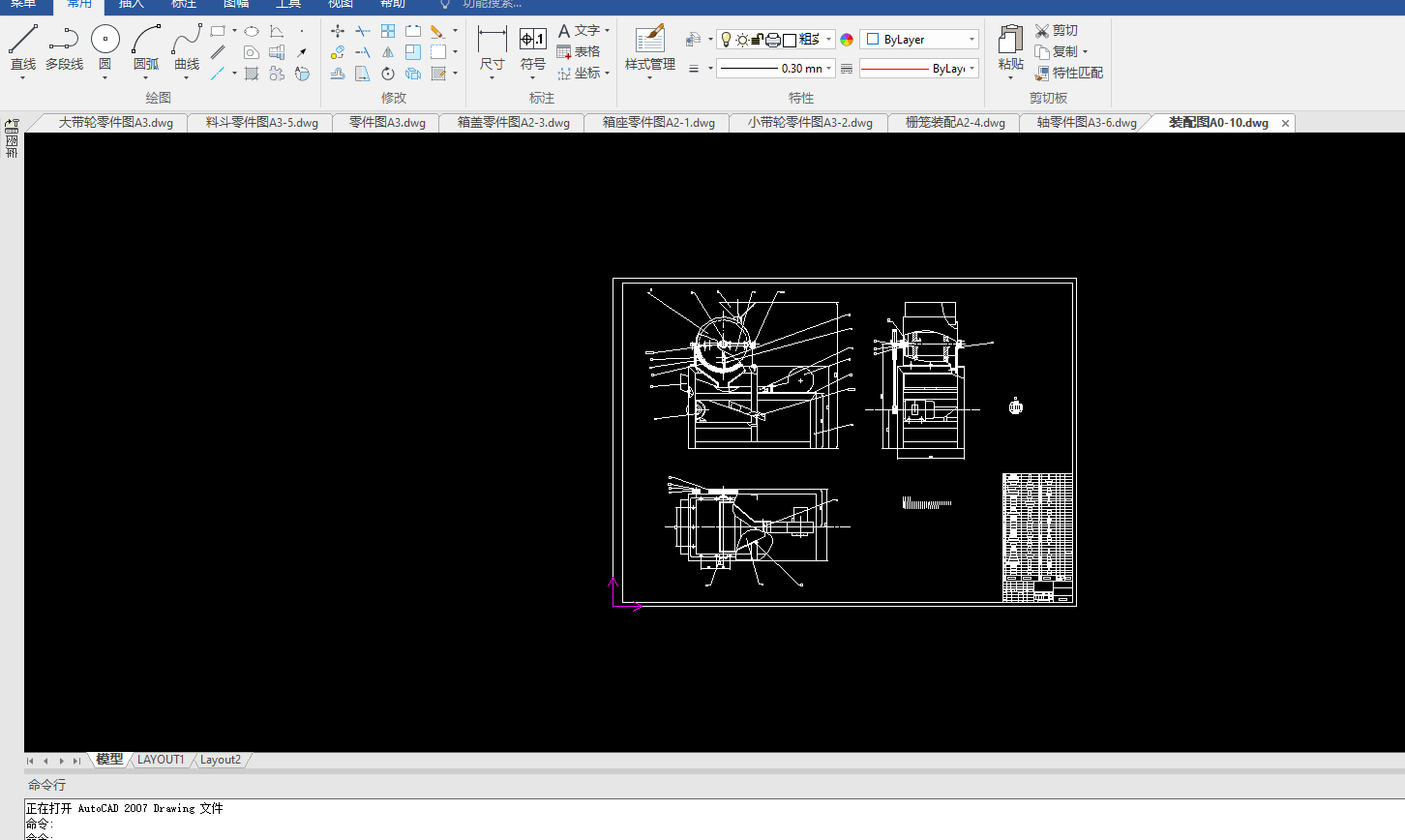

2.1 挤压式核桃外皮清理与分级装置的结构

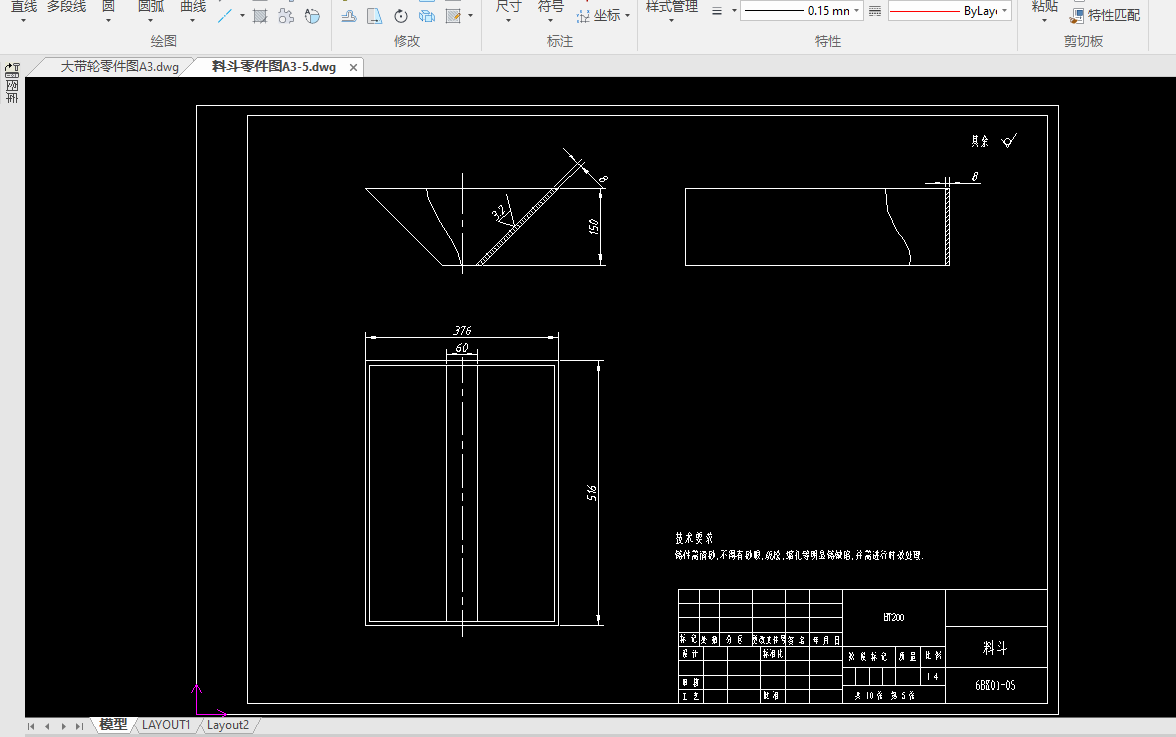

2.2 工作原理

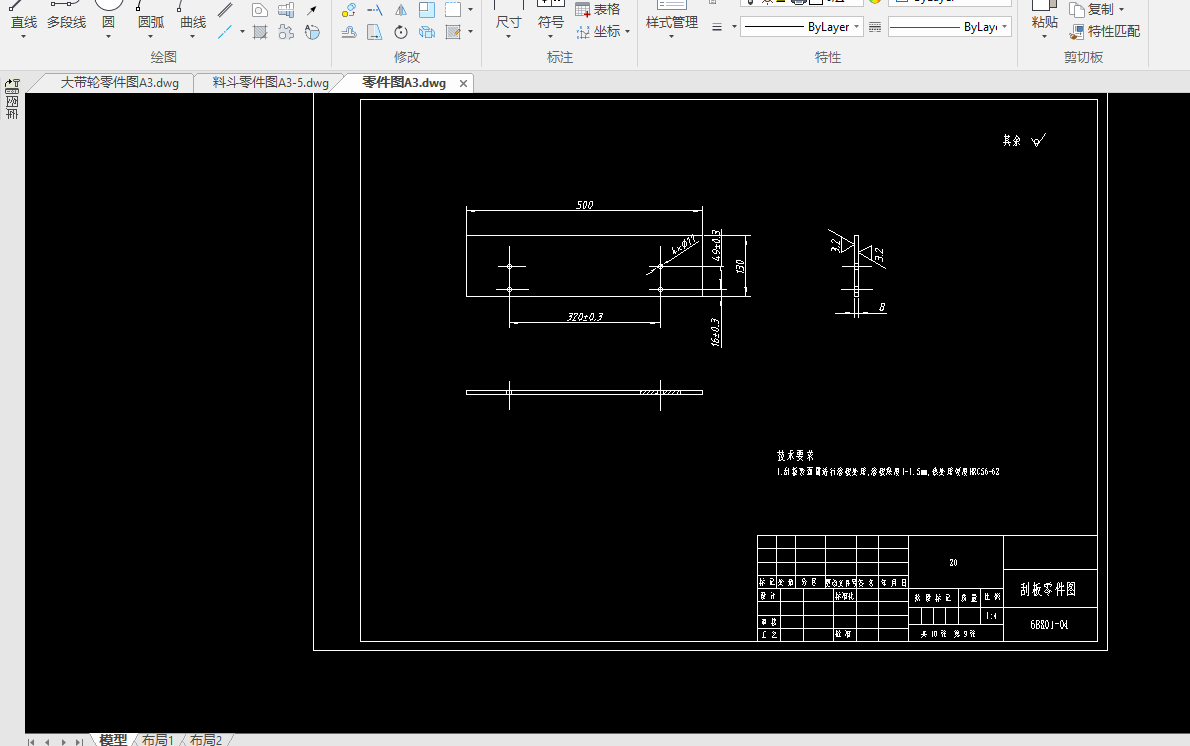

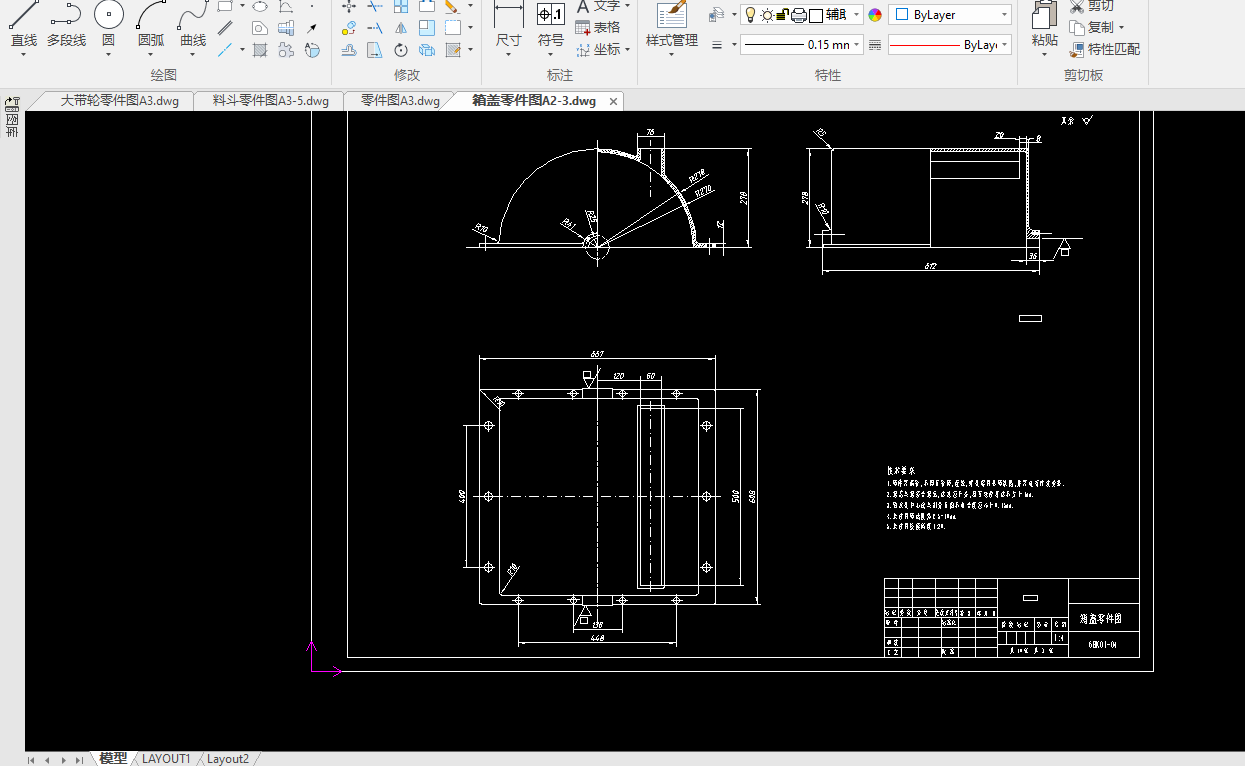

3 核桃外皮清理与分级装置主要部件的结构设计

3.1 设计前各项参数的确定

3.1.1 滚刀的半径及转速初定

3.1.2 滚刀所需功率计算

3.1.3 传动方案拟定

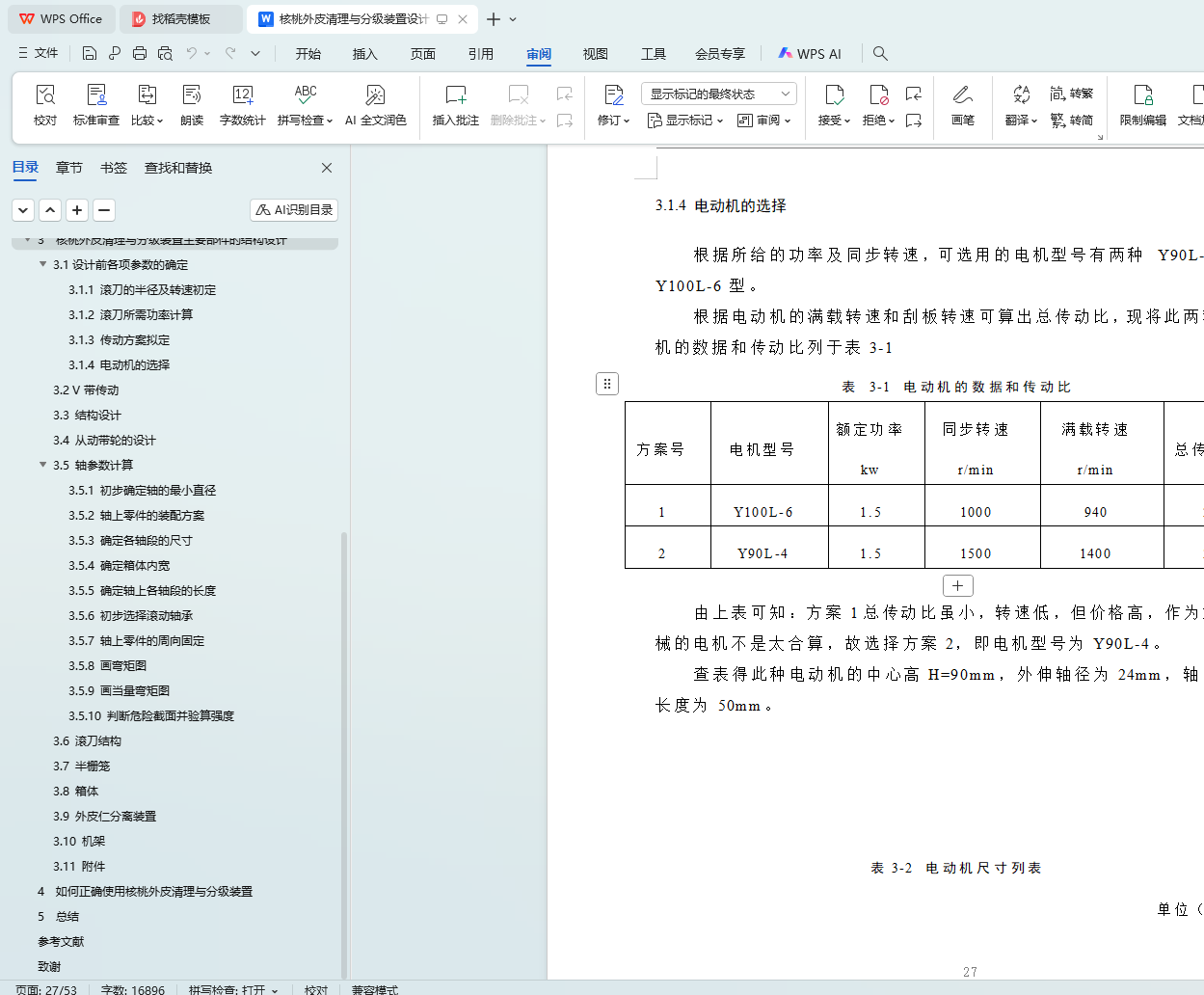

3.1.4 电动机的选择

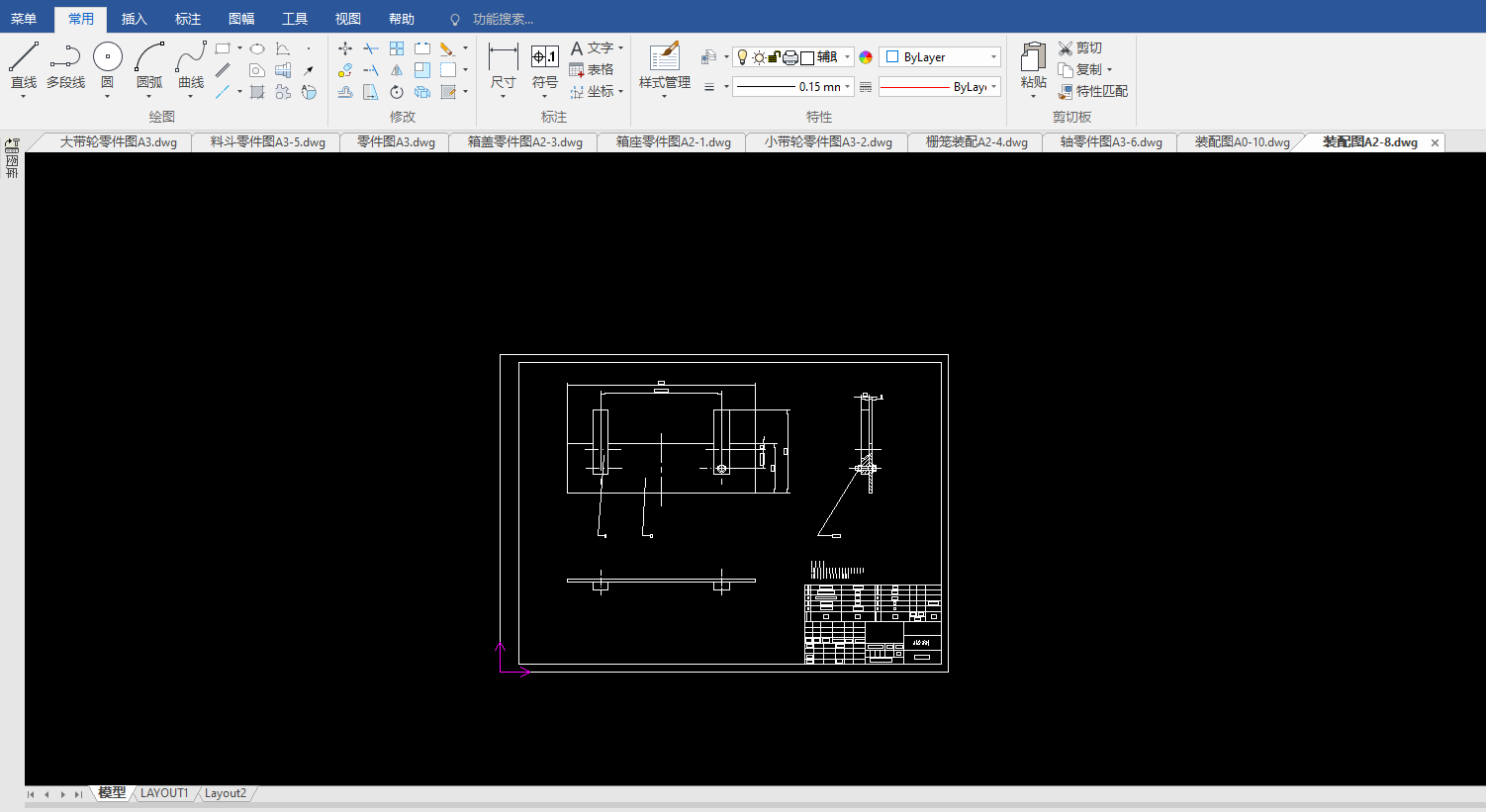

3.2 V带传动

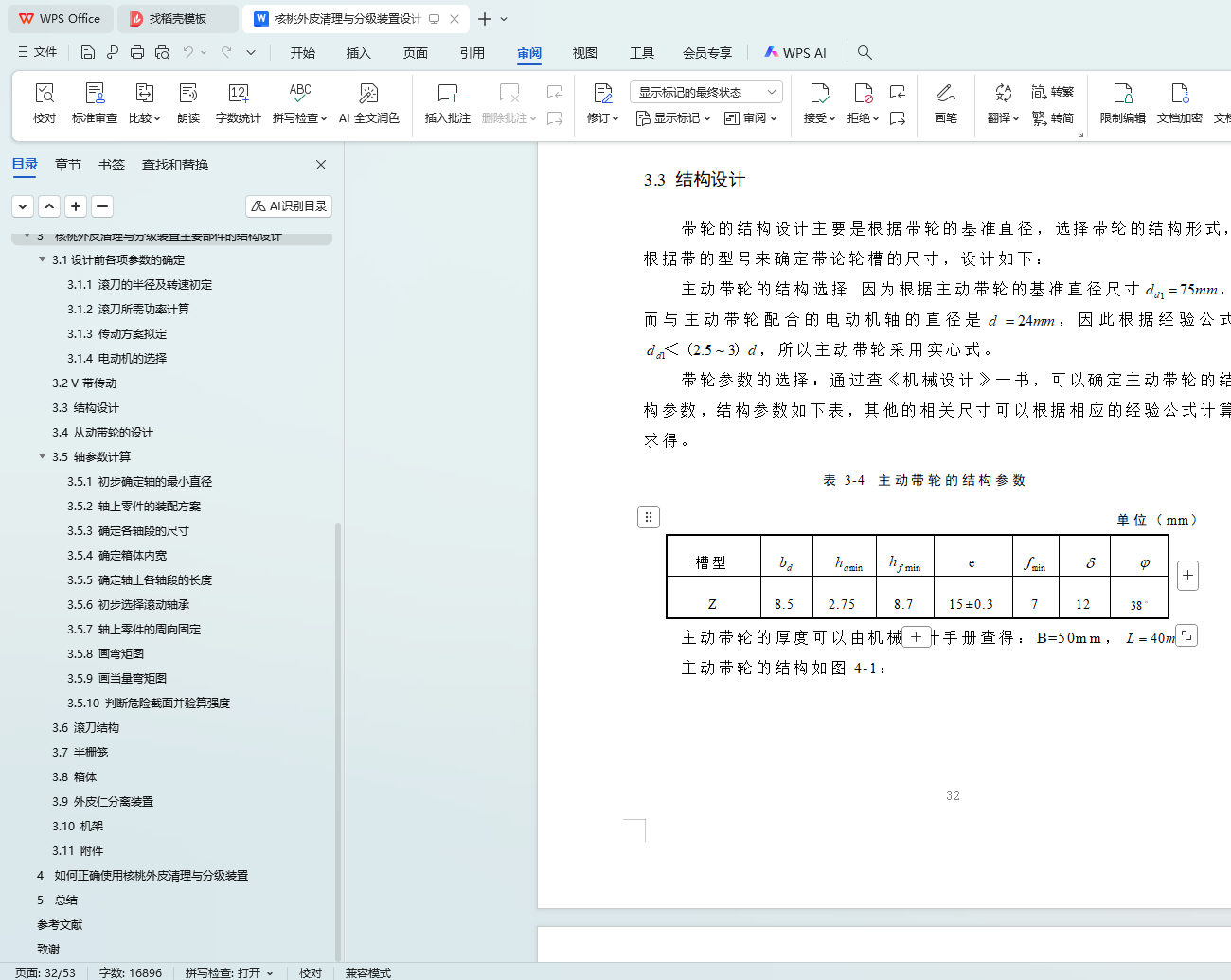

3.3 结构设计

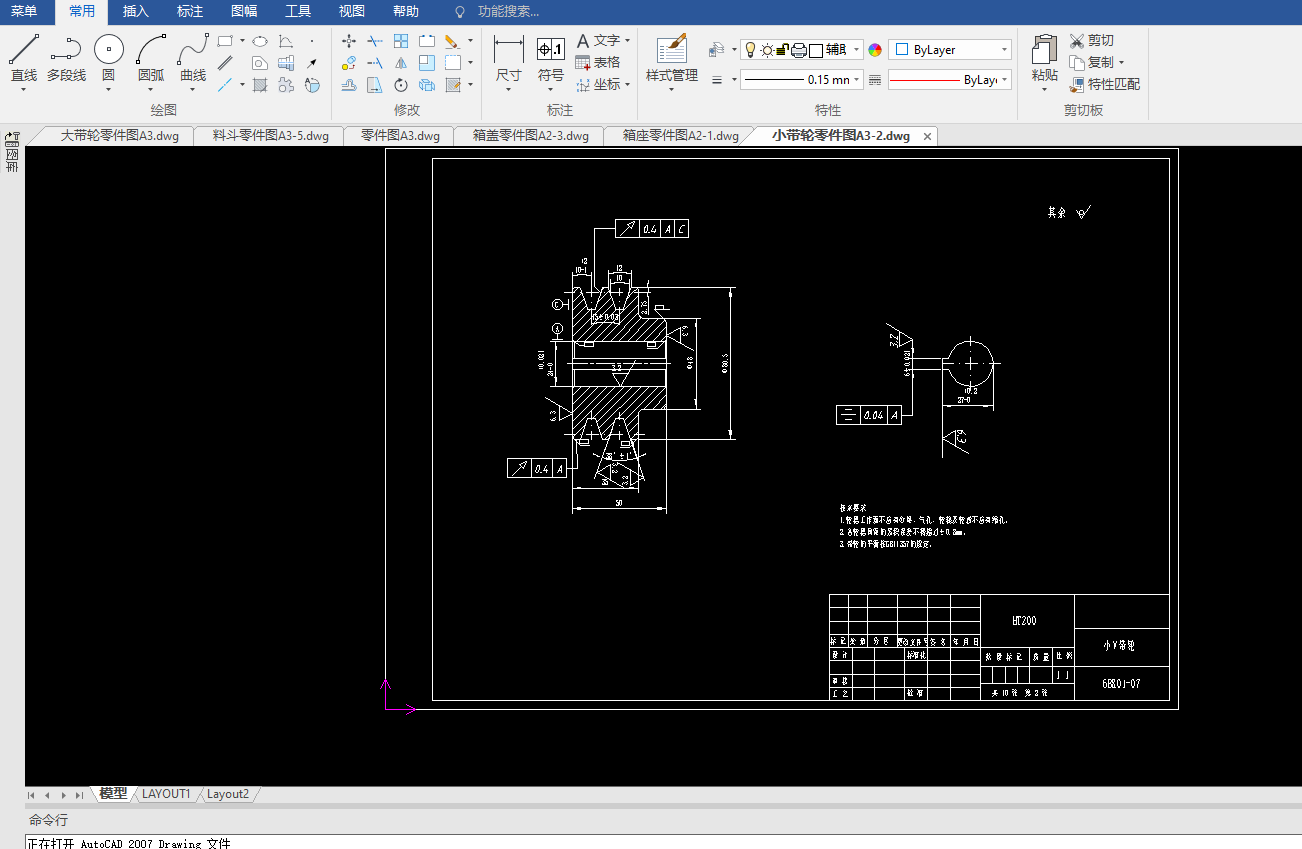

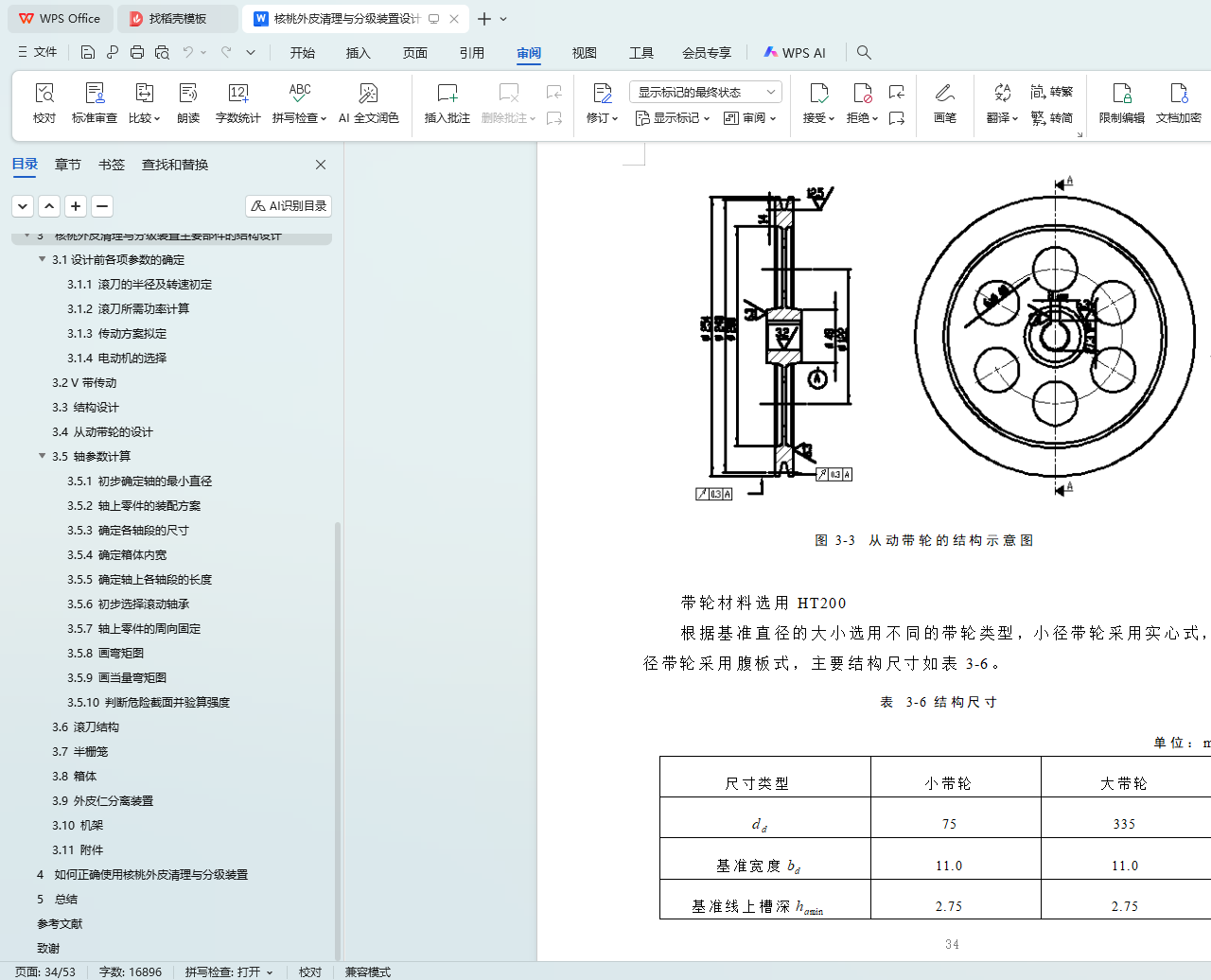

3.4 从动带轮的设计

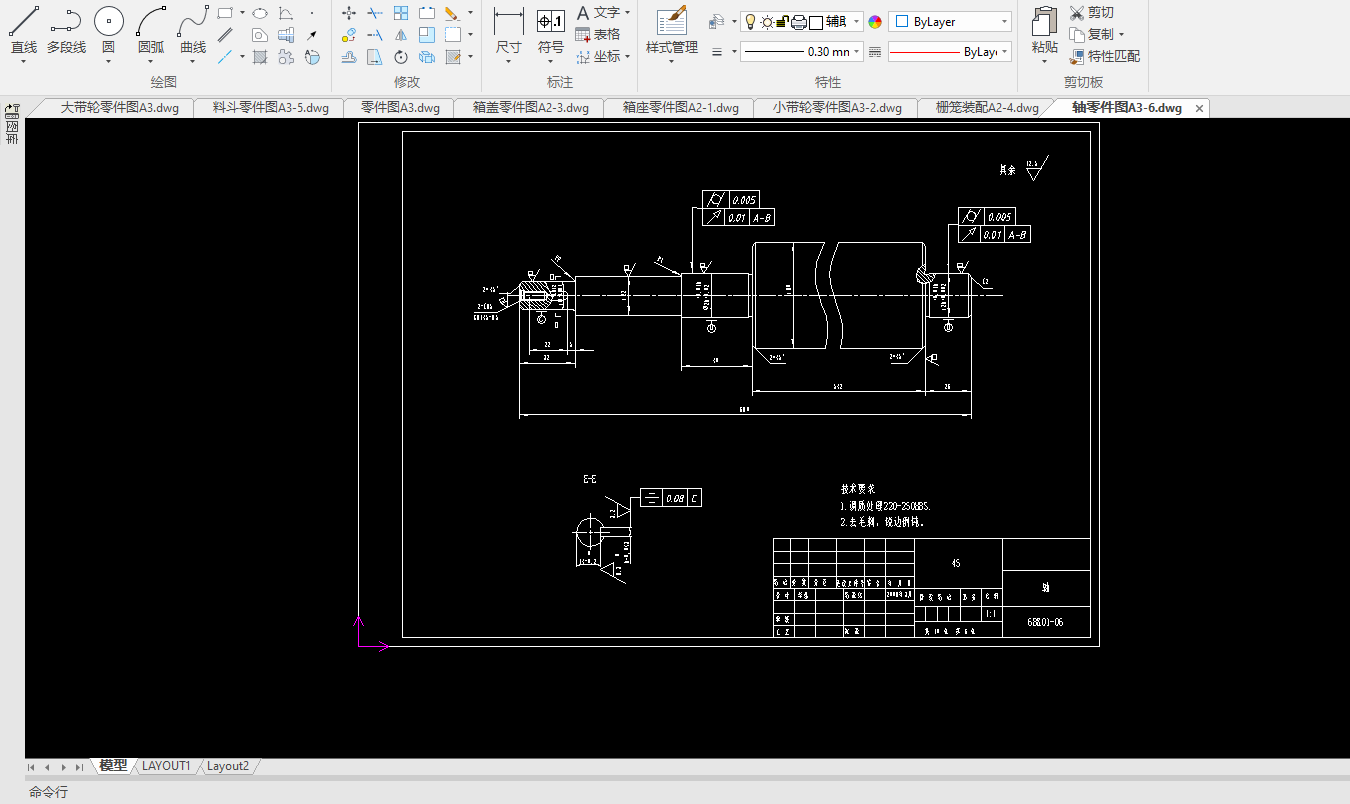

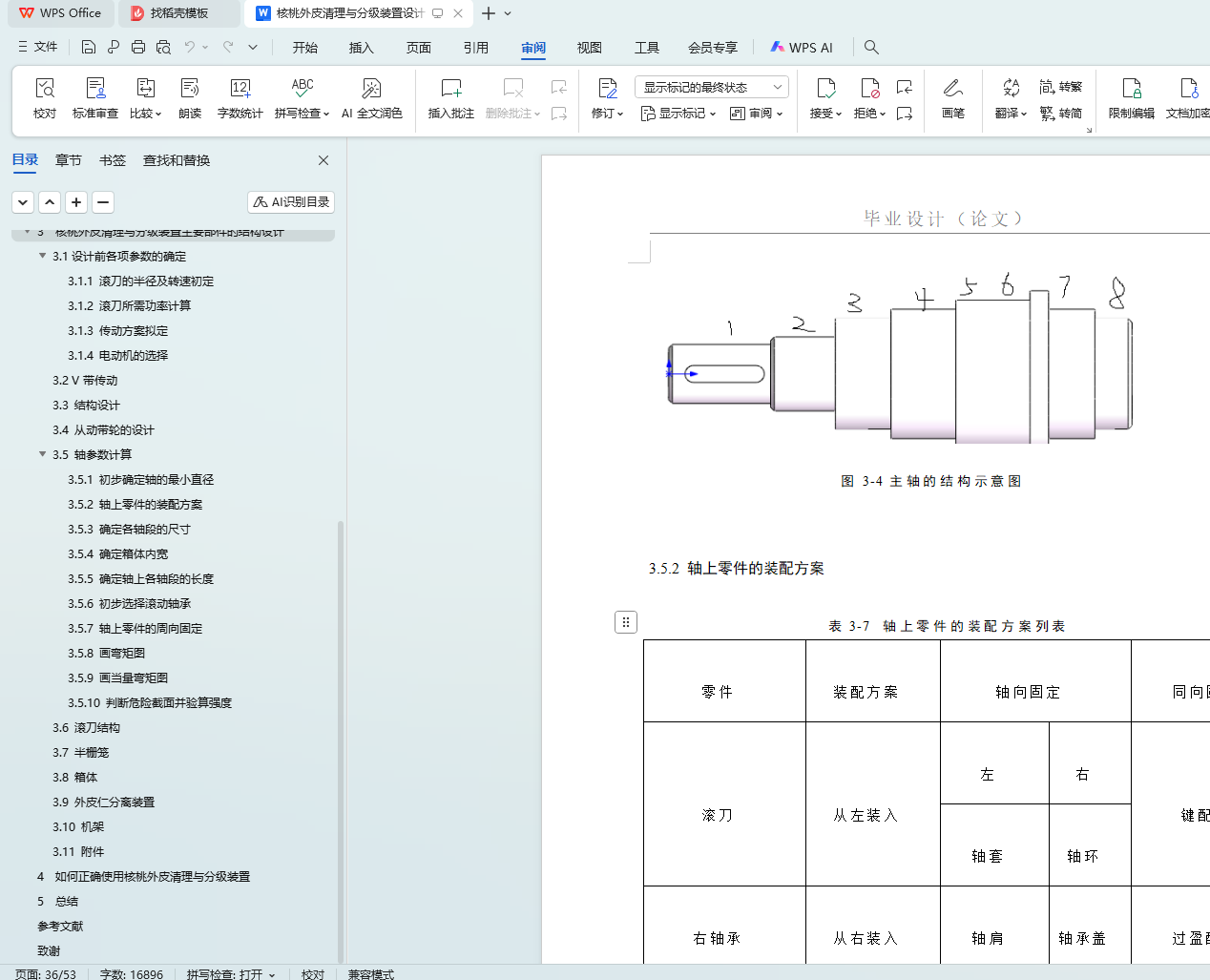

3.5 轴参数计算

3.5.1 初步确定轴的最小直径

3.5.2 轴上零件的装配方案

3.5.3 确定各轴段的尺寸

3.5.4 确定箱体内宽

3.5.5 确定轴上各轴段的长度

3.5.6 初步选择滚动轴承

3.5.7 轴上零件的周向固定

3.5.8 画弯矩图

3.4.7 画转矩图

3.5.9 画当量弯矩图

3.5.10 判断危险截面并验算强度

3.6 滚刀结构

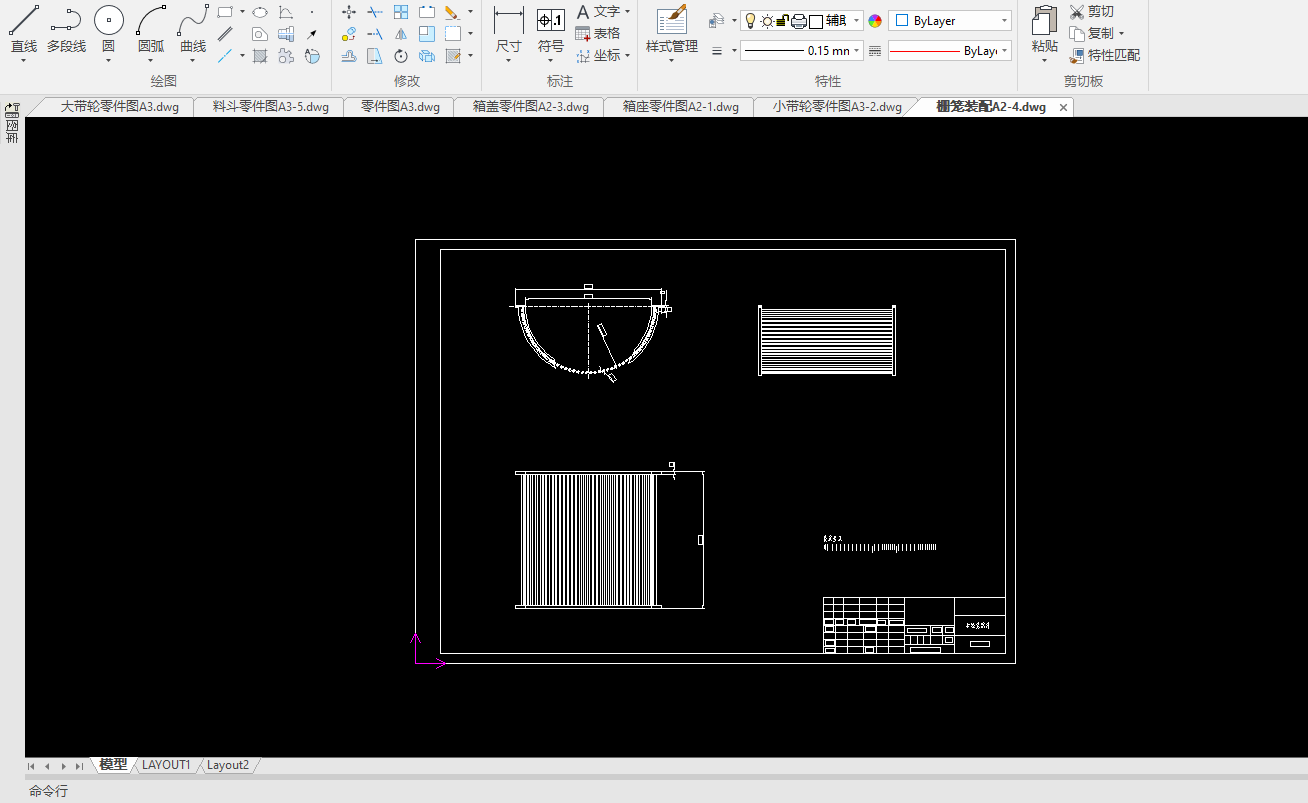

3.7 半栅笼

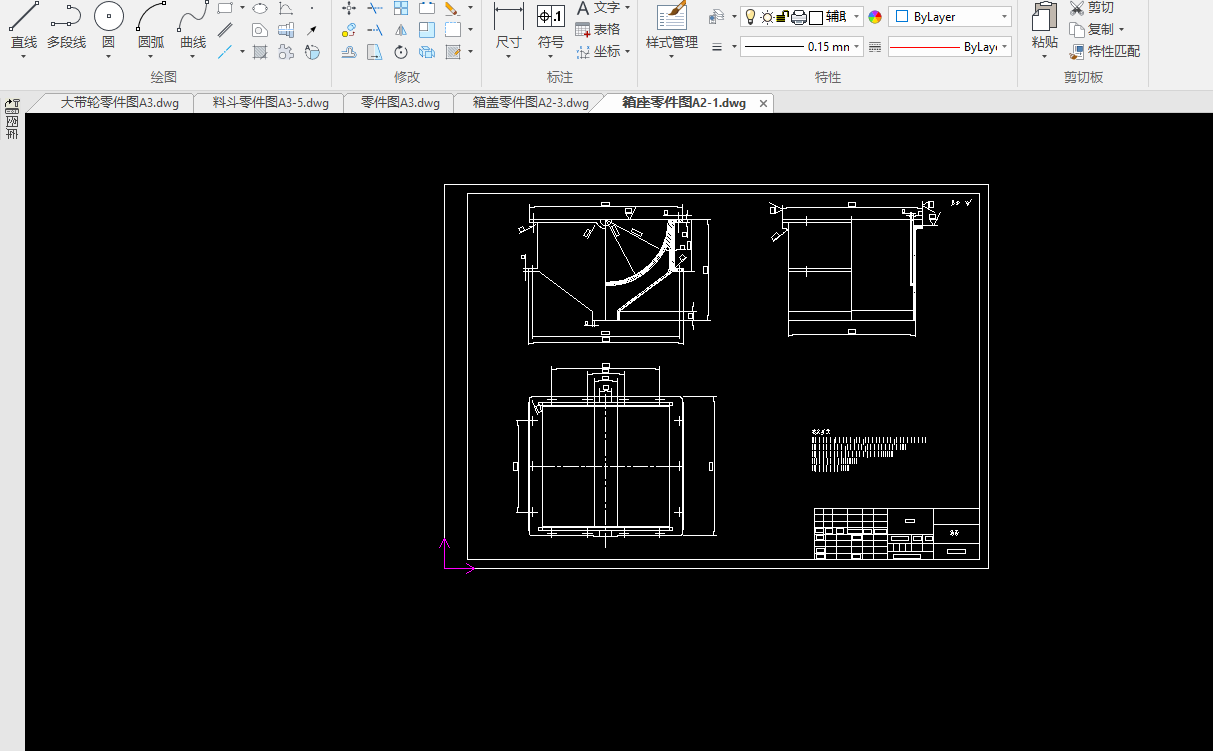

3.8 箱体

3.9 外皮仁分离装置

3.10 机架

3.11 附件

4 如何正确使用核桃外皮清理与分级装置

5 总结

参考文献

致谢