摘 要

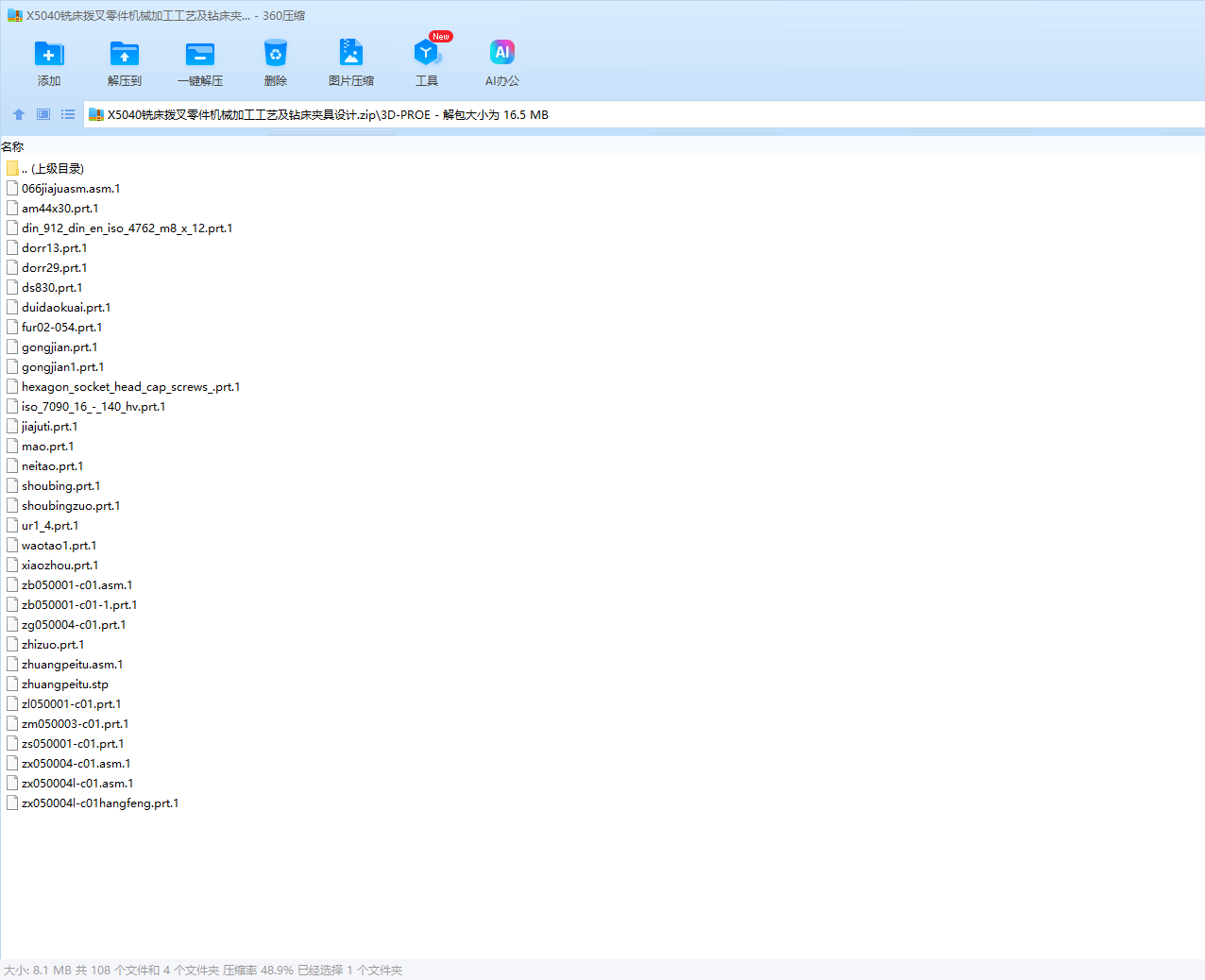

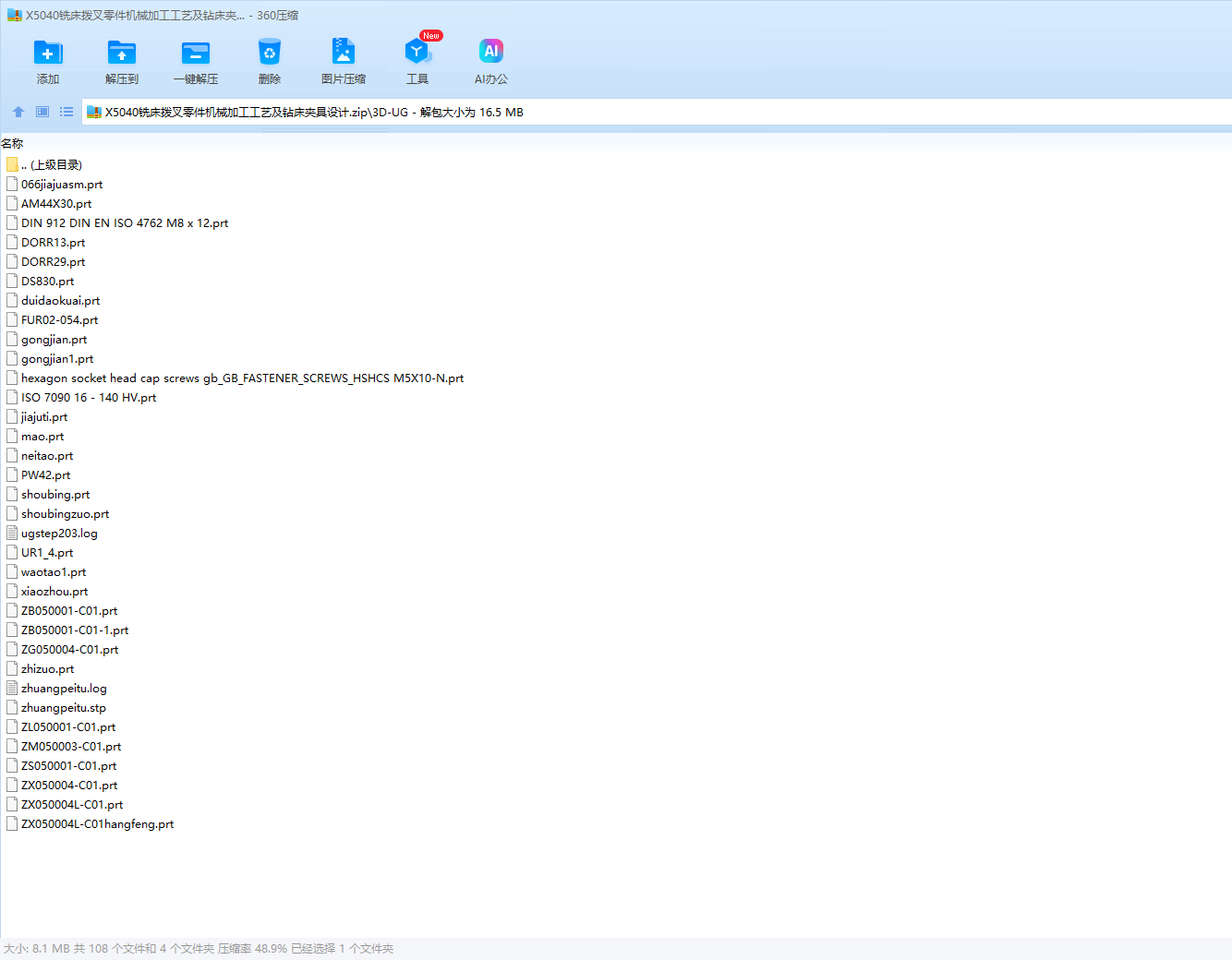

本研究旨在探讨X5040铣床拨叉零件的机械加工工艺及钻床夹具设计,涵盖零件加工工艺设计、工序设计以及专用夹具设计三大核心部分。首先,在零件加工工艺设计阶段,我们深入分析零件结构,明确其工艺特性,并据此设计毛坯结构。随后,选定加工基准,规划出合理的工艺路线,这是确保零件加工精度和效率的关键步骤。

在工序设计阶段,我们详细计算了零件各个工步的工序尺寸,这一过程中,决定各工序的工艺装备及切削用量至关重要。切削用量的合理选择不仅能提高加工效率,还能有效延长刀具寿命,降低生产成本。

最后,我们进行了专用夹具的设计。夹具作为机械加工中的重要辅助工具,其设计质量直接关系到零件的加工精度和生产效率。因此,我们精心选择了夹具的各个组成部件,包括定位元件、夹紧元件、引导元件等,并设计了夹具体与钻床的连接部件。此外,我们还对夹具定位时产生的定位误差进行了计算和分析,以确保夹具结构的合理性和可靠性。

通过本研究,我们期望能够优化X5040铣床拨叉零件的机械加工工艺,提高加工效率和产品质量,同时为类似零件的加工工艺及夹具设计提供参考和借鉴。

关键词:X5040铣床拨叉零件、机械加工工艺、工序设计、切削用量、夹具设计、定位误差

Abstract

The purpose of this study is to explore the machining process and drill machine fixture design of X5040 milling machine, covering three core parts: machining process design, process design and special fixture design. First of all, in the design stage of the part processing process, we deeply analyze the structure of the parts, clarify its process characteristics, and design the blank structure accordingly. Subsequently, the processing benchmark is selected and a reasonable process route is planned, which is a key step to ensure the accuracy and efficiency of parts.

In the process design stage, we calculated the process size of each step in detail. In this process, it is very important to determine the process equipment and cutting amount of each process. The reasonable selection of cutting amount can not only improve the processing efficiency, but also effectively extend the tool life and reduce the production cost.

Finally, we have done the design of a special fixture. As an important auxiliary tool in machining, the design quality of the fixture is directly related to the machining accuracy and production efficiency of the parts. Therefore, we have carefully selected the various components of the clamp, including positioning elements, clamping elements, guide components, etc., and designed the specific connection components between the clamp and the drilling machine. In addition, we calculated and analyzed the positioning error generated during the clamp positioning to ensure the rationality and reliability of the clamp structure.

Through this study, we expect to optimize the machining process of X5040 milling parts, improve the processing efficiency and product quality, and provide reference for the processing process and fixture design of similar parts.

Key words: X5040 milling machine fork parts, machining technology, process design, cutting dosage, fixture design, positioning error

目录

摘 要

Abstract

绪论

1.夹具设计目的与意义

1.1钻床夹具的现状

1.2 现代钻床夹具的发展方向

1.3本课题主要讨论的问题

第1章 夹具设计的概论

1.1 钻床夹具的概述

1.1.1 钻床夹具概述

1.1.2 钻床夹具的种类

1.1.3 钻床夹具的组成

1.2 铣床夹具的分类

1.3 铣削专用夹具的设计要点

1.4 铣床夹具的安装

1.5 工件的定位与误差分析

1.5.1 工件定位的基本原理

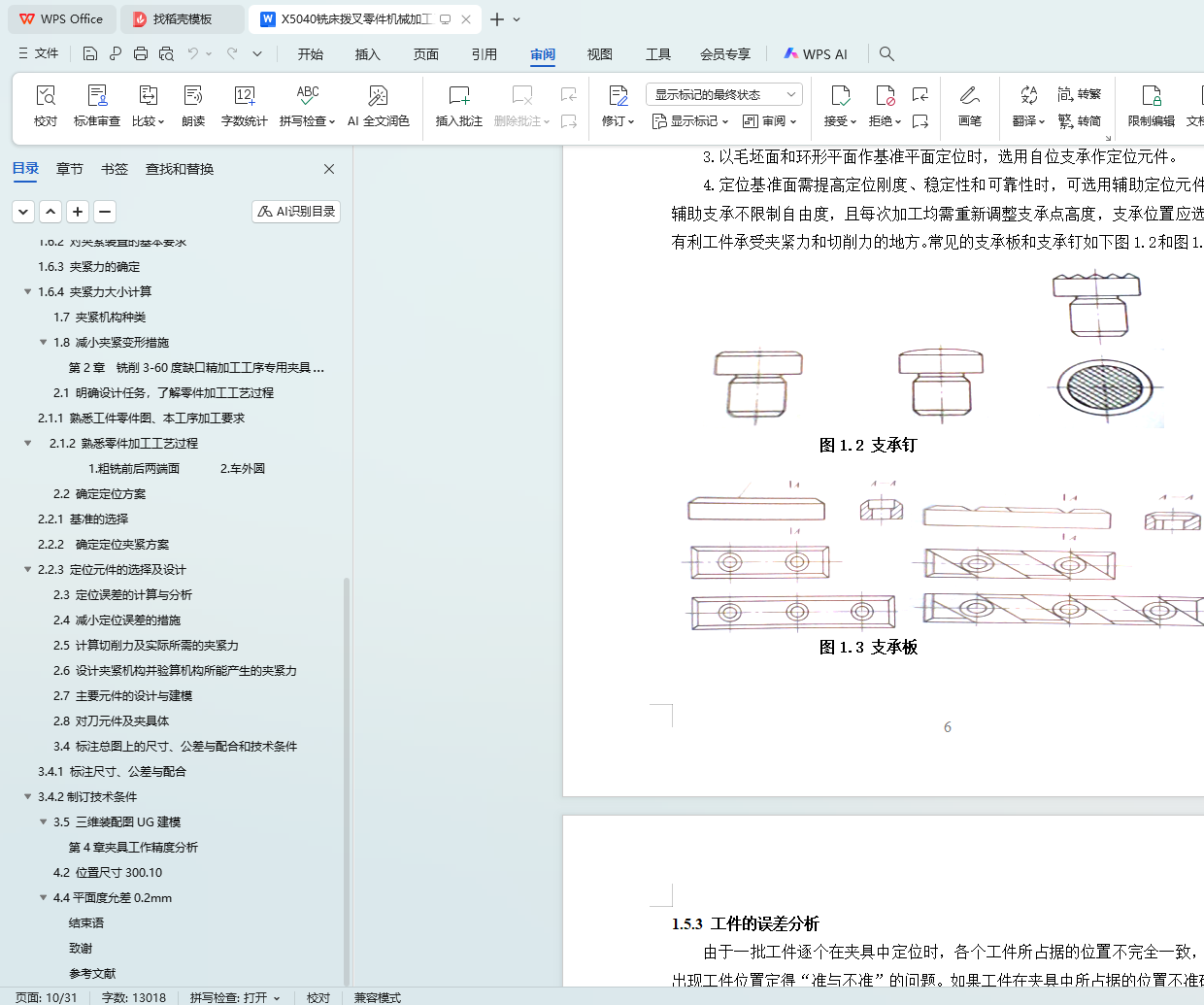

1.5.2 定位方法与定位元件

1.5.3 工件的误差分析

1.5.4 定位误差产生的原因

1.6 夹紧装置

1.6.1夹紧装置的组成

1.6.2 对夹紧装置的基本要求

1.6.3 夹紧力的确定

1.6.4 夹紧力大小计算

1.7 夹紧机构种类

1.8 减小夹紧变形措施

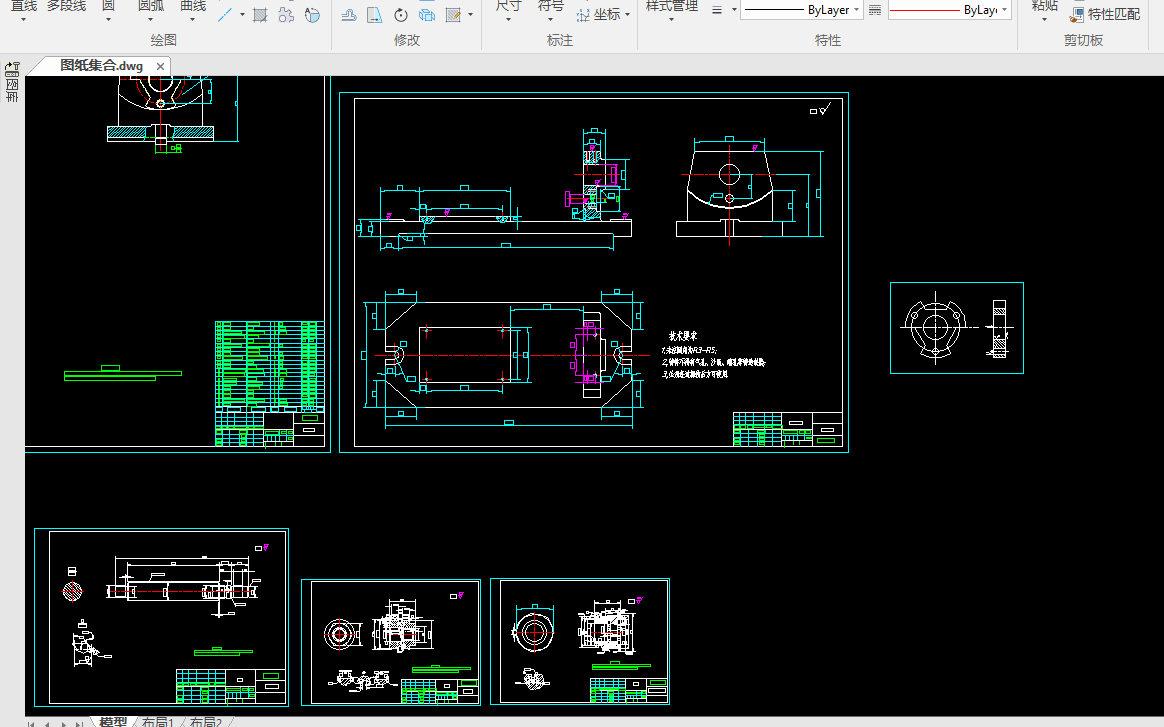

第2章 铣削3-60度缺口精加工工序专用夹具的设计

2.1 明确设计任务,了解零件加工工艺过程

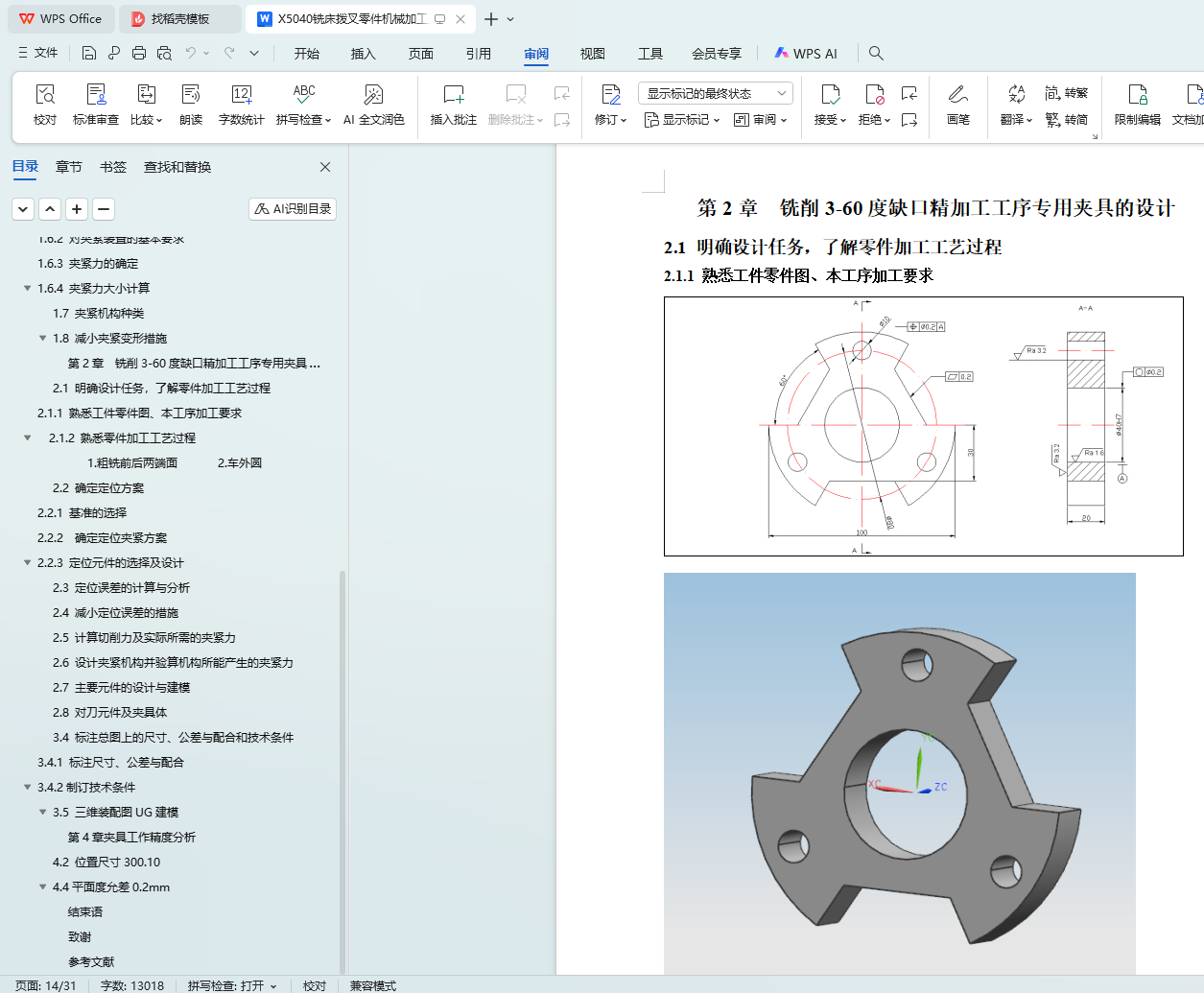

2.1.1 熟悉工件零件图、本工序加工要求

2.1.2 熟悉零件加工工艺过程

2.2.1 基准的选择

2.2.2 确定定位夹紧方案

2.2.3 定位元件的选择及设计

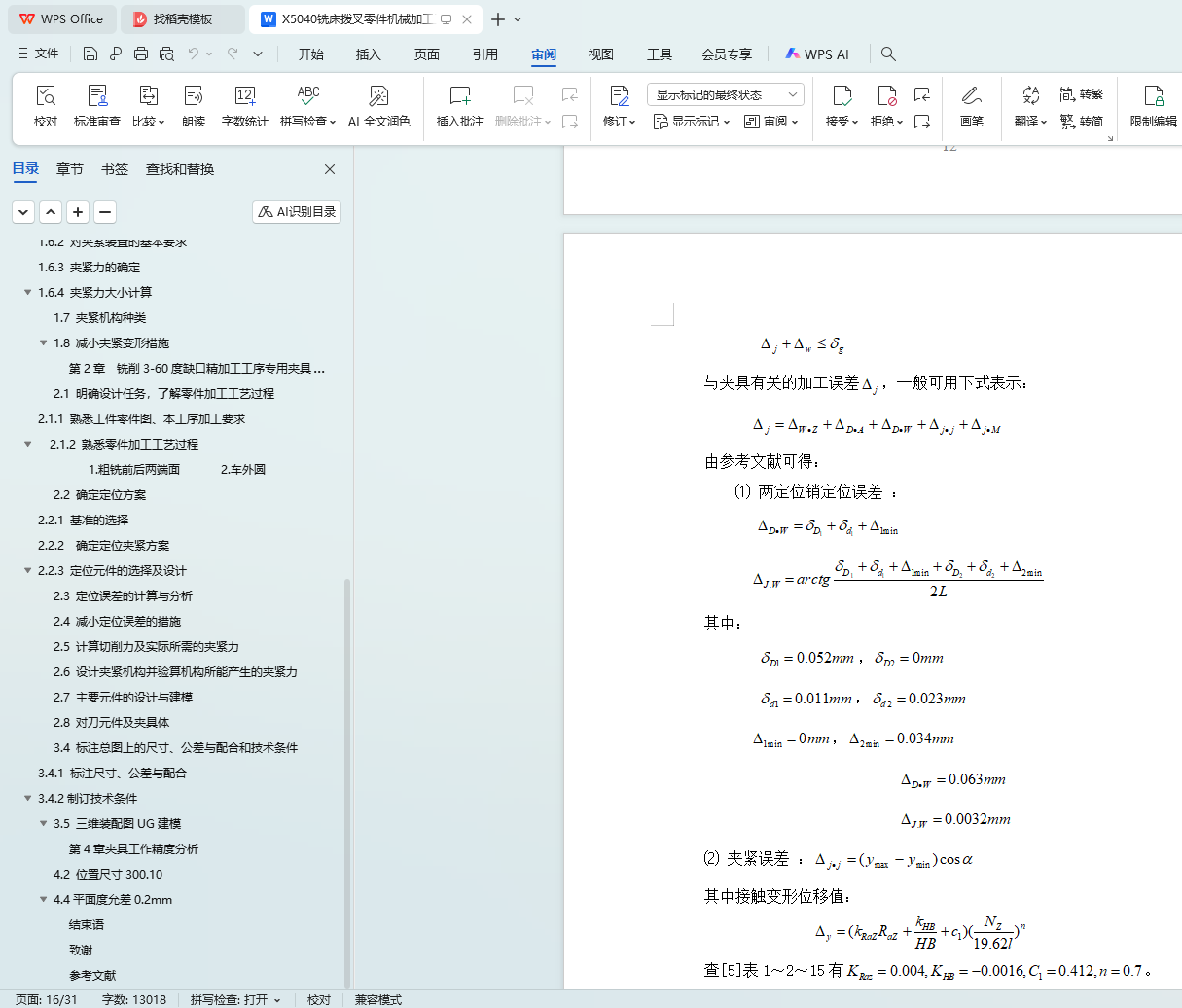

2.3 定位误差的计算与分析

2.4 减小定位误差的措施

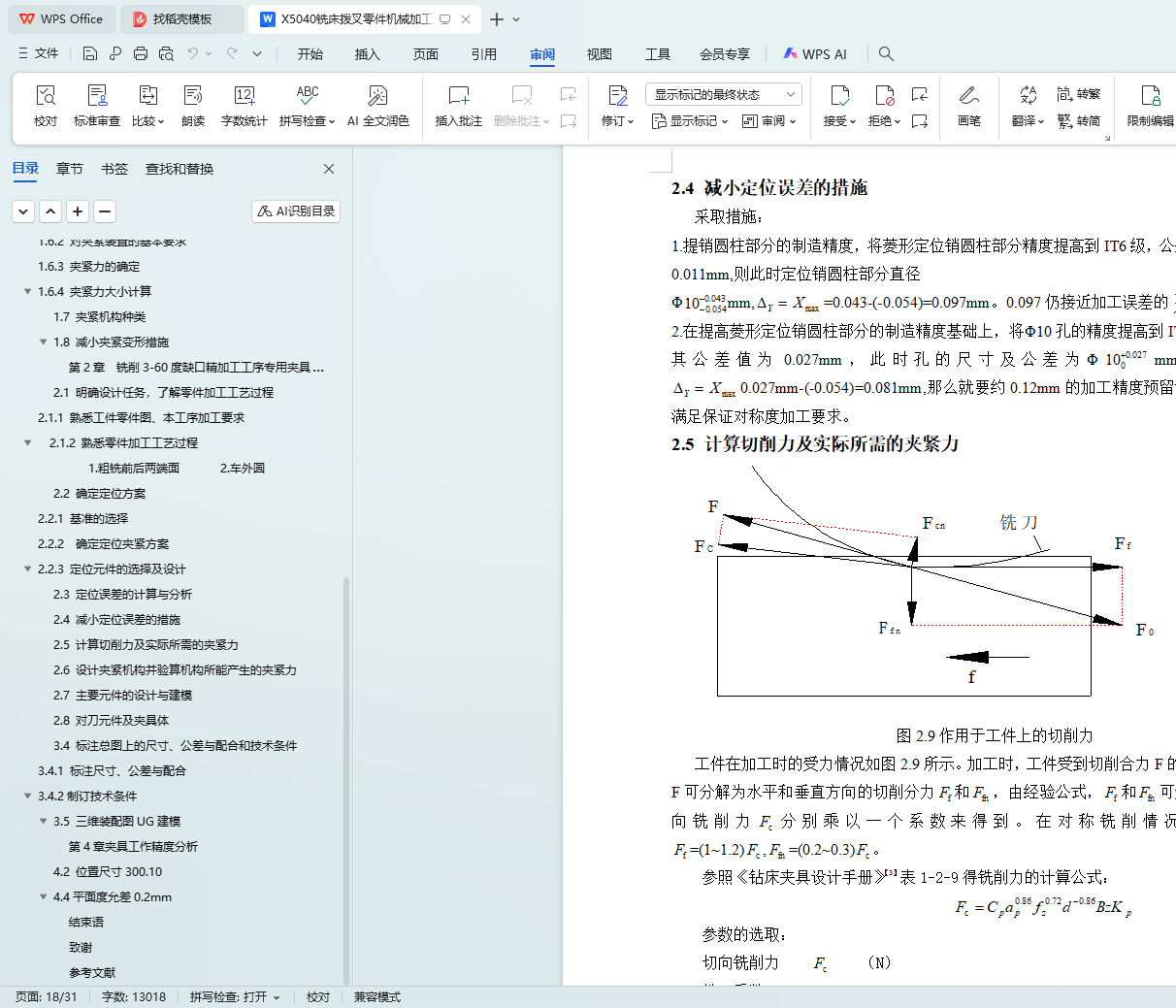

2.5 计算切削力及实际所需的夹紧力

2.6 设计夹紧机构并验算机构所能产生的夹紧力

2.7 主要元件的设计与建模

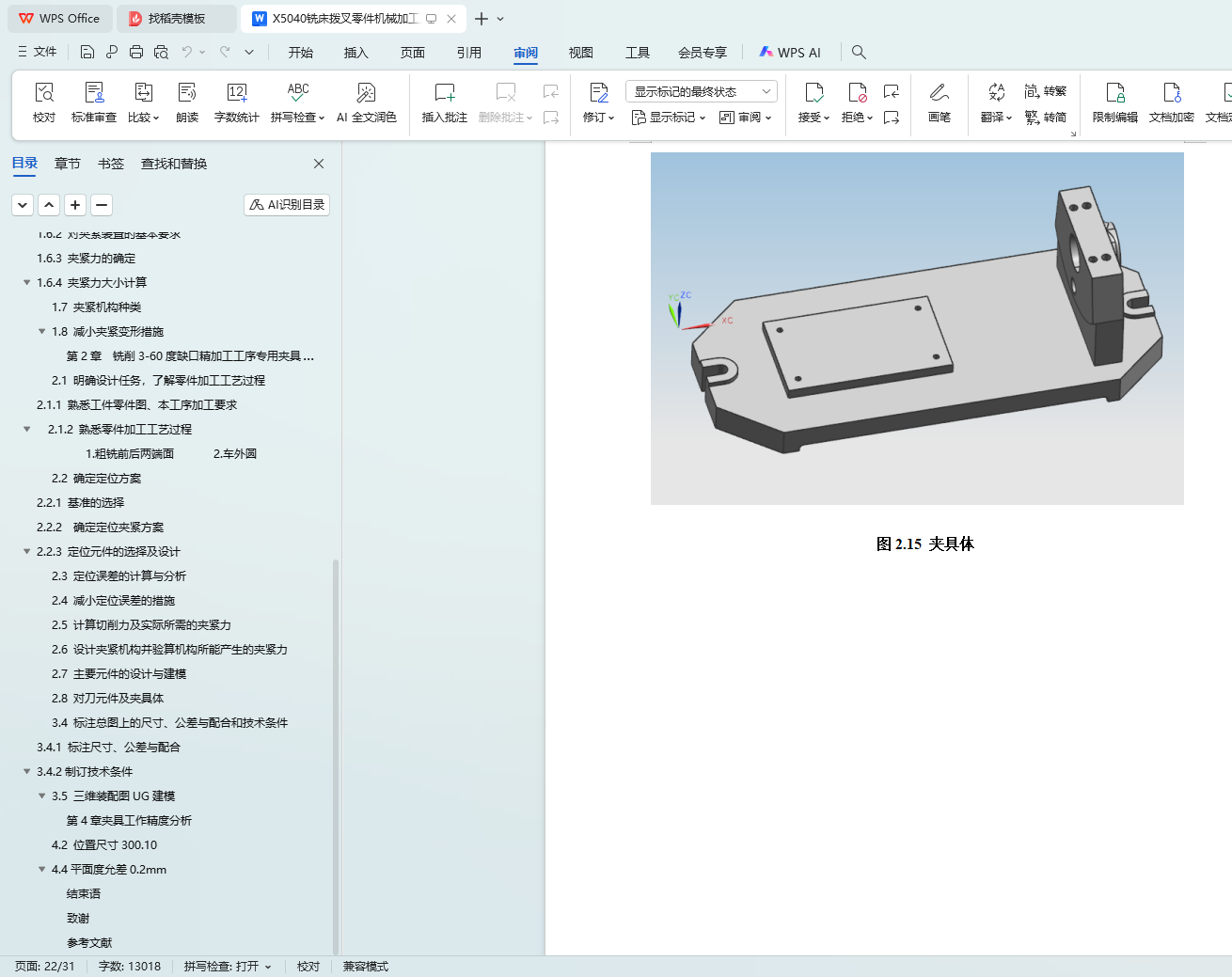

2.8 对刀元件及夹具体

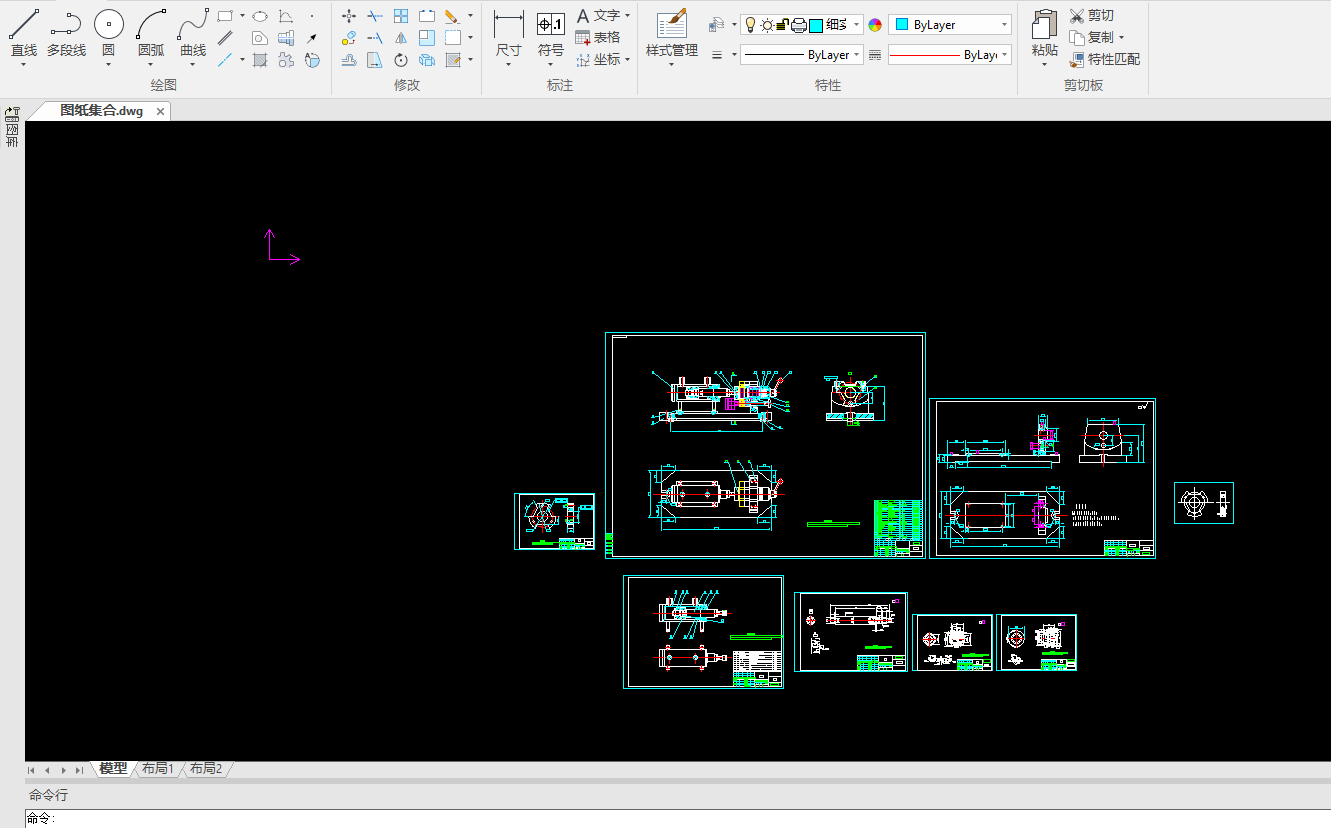

第3章 夹具图绘制

3.1 工序图

3.2 夹具体零件图

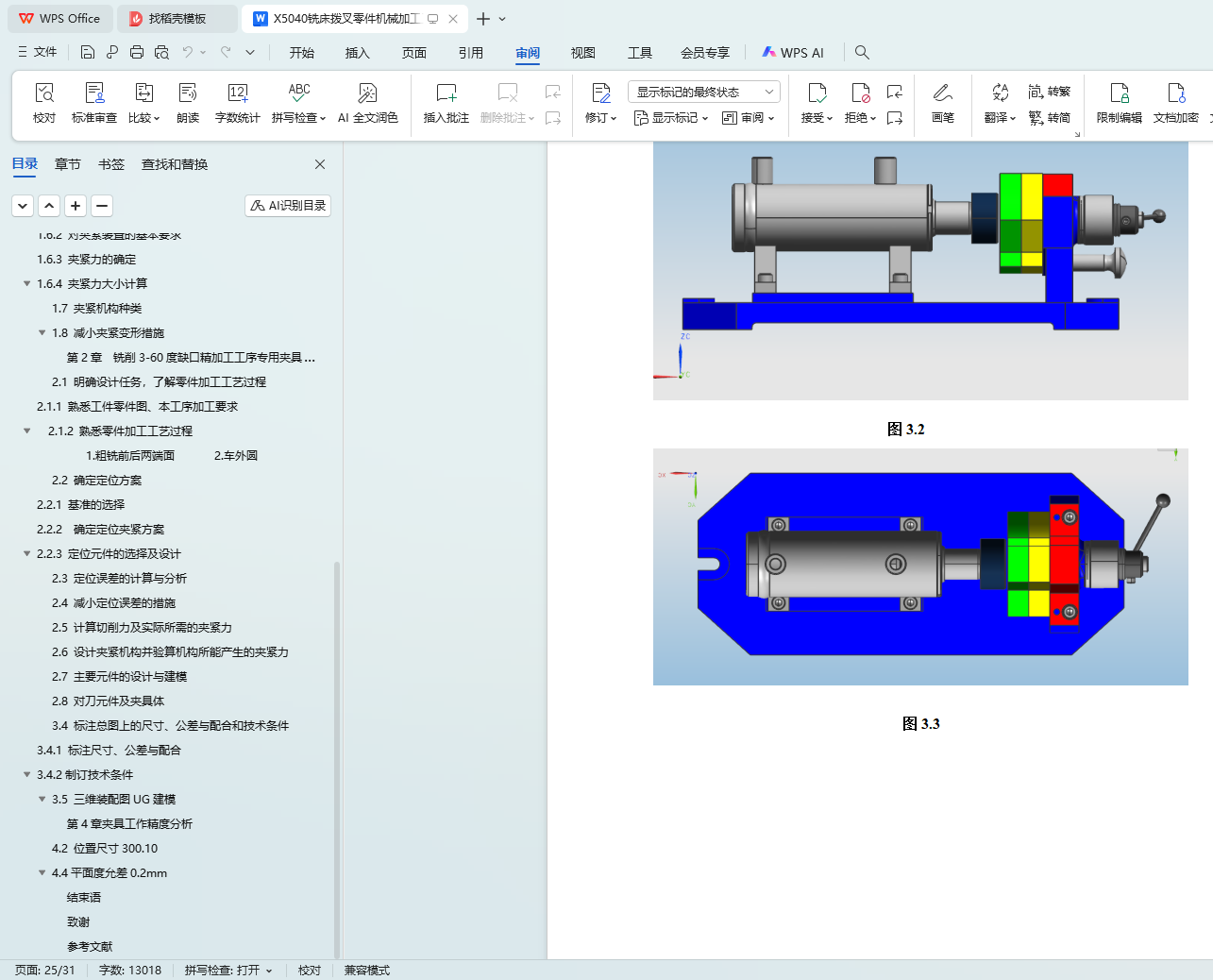

3.3 绘制夹具装配总图

3.4 标注总图上的尺寸、公差与配合和技术条件

3.4.1 标注尺寸、公差与配合

3.4.2制订技术条件

3.5 三维装配图UG建模

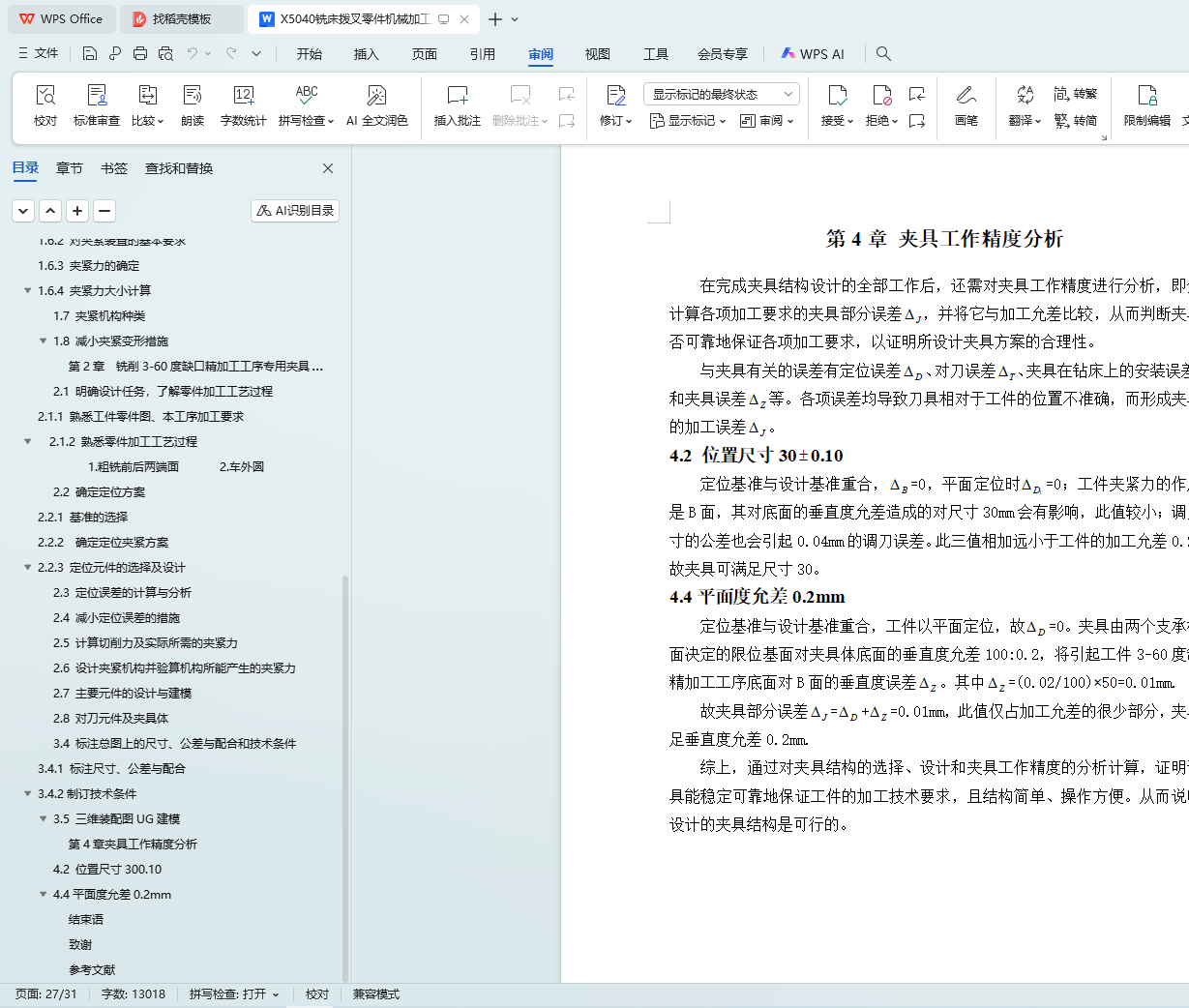

第4章 夹具工作精度分析

4.2 位置尺寸30 0.10

0.10

4.4平面度允差0.2mm

结束语

致谢

参考文献