摘要

随着农业种植成本的增加和农产品品质要求的提高,农药的利用率成为农业生产中的关键问题。据农业部公布的数据,我国农药利用率为36.6%,虽然比过去有所提高,但仍存在较大的提升空间。特别是在新疆这一棉花种植大区,棉花作为支柱产业,其植保农药的利用率对于棉花产量和品质具有重要影响。

新疆大力推广机采棉,对棉花种植和植保提出了更高要求。在棉花采摘前,实施脱叶处理是提升机采棉加工品级和质量的关键环节。然而,传统的棉花喷雾机在喷洒脱叶剂时,由于棉花叶子茂密,往往难以确保脱叶剂均匀喷洒到每一片叶子,特别是下部的叶子,导致脱叶效果不佳,影响后续采棉机的采收和棉花的等级评定。

针对这一问题,自走式风送喷雾机以其独特的优势在棉花脱叶剂喷洒中展现出巨大的应用潜力。该喷雾机通过优化喷雾系统和风送系统的设计,能够实现对雾滴粒径、喷头流量、喷洒角度等参数的精确控制,确保脱叶剂能够均匀覆盖到棉花的每一片叶子,包括下部难以喷洒到的区域。同时,自走式风送喷雾机还配备了灵活的传动机构和悬挂系统,能够适应不同地形和作物类型的作业需求,提高喷雾作业的效率和效果。

此外,自走式风送喷雾机还具有操作简便、劳动强度低、作业安全性高等优点。操作人员只需通过简单的启动操作,即可轻松完成整个喷雾过程,大大降低了人工喷洒的劳动强度,提高了作业的安全性和舒适度。

综上所述,自走式风送喷雾机在棉花脱叶剂喷洒中的应用,能够显著提高农药的利用率,确保脱叶剂均匀喷洒到棉花的每一片叶子,提高棉花的脱叶效果和品质等级。这对于提升机采棉的加工品级和质量、增加农户收入、推动农业可持续发展具有重要意义。因此,进一步研究和推广自走式风送喷雾机在棉花植保中的应用,将具有重要的现实意义和广阔的市场前景。

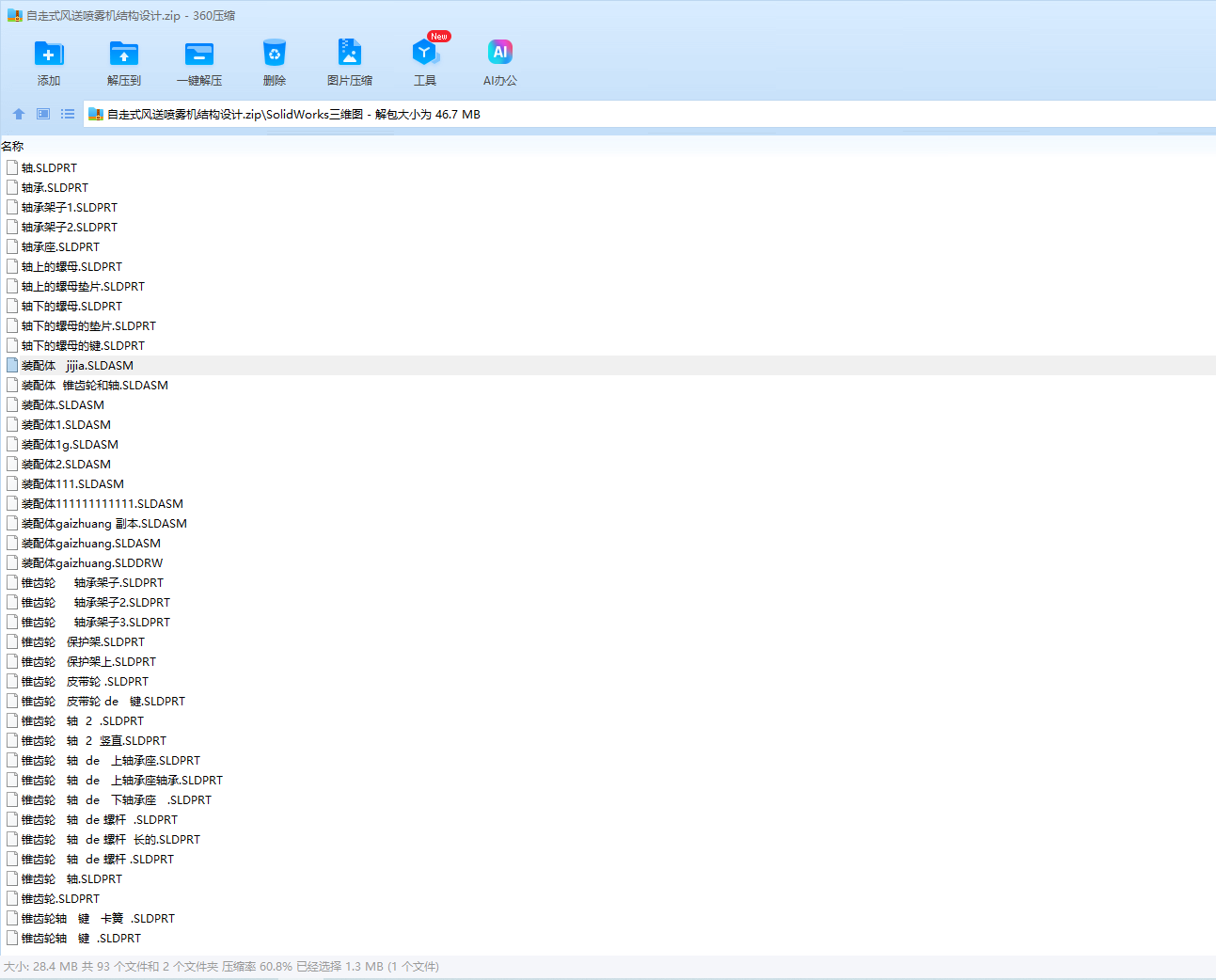

关键词:自走式 ;喷雾机;风扇助力;cad图纸;Sw三维图

Abstract

With the increase of agricultural planting cost and the improvement of the quality requirements of agricultural products, the utilization rate of pesticides has become a key problem in agricultural production. According to the data released by the Ministry of Agriculture, the utilization rate of pesticides in China is 36.6%, which is higher than in the past, but there is still a large room for improvement. Especially in Xinjiang, a cotton planting region, cotton as a pillar industry, the utilization rate of plant protection pesticides has an important impact on the yield and quality of cotton.

Xinjiang has vigorously promoted mechanical cotton picking, which has put forward higher requirements for cotton planting and plant protection. Before cotton picking, the implementation of defoliation treatment is the key link to improve the quality of cotton processing. However, when traditional cotton sprayers spray the defoliation agent, due to the dense cotton leaves, it is often difficult to ensure that the defoliation agent is evenly sprayed into each leaf, especially the lower leaves, resulting in poor defoliation effect, affecting the subsequent harvesting of cotton pickers and the grading of cotton.

In view of this problem, the self-propelled air delivery spray machine has shown great application potential in cotton leaflet spraying with its unique advantages. By optimizing the design of the spray system and air transmission system, the sprayer can achieve accurate control of the droplet particle size, nozzle flow, spray Angle and other parameters, ensuring that the stripping agent can evenly cover every leaf of cotton, including the lower area that is difficult to spray. At the same time, the self-propelled air delivery sprayer is also equipped with flexible transmission mechanism and suspension system, which can adapt to the operation needs of different terrain and crop types, and improve the efficiency and effect of the spray operation.

In addition, the self-propelled air delivery sprayer also has the advantages of simple operation, low labor intensity and high operation safety. Operators only need to easily complete the whole spray process through a simple start operation, which greatly reduces the labor intensity of manual spraying and improves the safety and comfort of the operation.

To sum up, the application of self-propelled air delivery sprayer in cotton defoliation agent spraying can significantly improve the utilization rate of pesticide, ensure that defoliation agent is evenly sprayed to every leaf of cotton, and improve the defoliation effect and quality grade of cotton. This is of great significance for improving the processing grade and quality of mechanized cotton picking, increasing the income of farmers and promoting the sustainable development of agriculture. Therefore, further research and promotion of the application of self-propelled air delivery sprayer in cotton plant protection will have great practical significance and broad market prospects.

Key words: self-propelled; sprayer; fan power; cad drawing; Sw 3 d drawing

目 录

1 绪论

1.1课题研究的意义

1.2国内的自走式风送喷雾机的现状

1.3 该产品的研究目的

1.3.1 研究的方法和内容

1.3.2预期的目标

1.4重点研究的关键问题及解决思路

1.4.2工作条件及解决方法

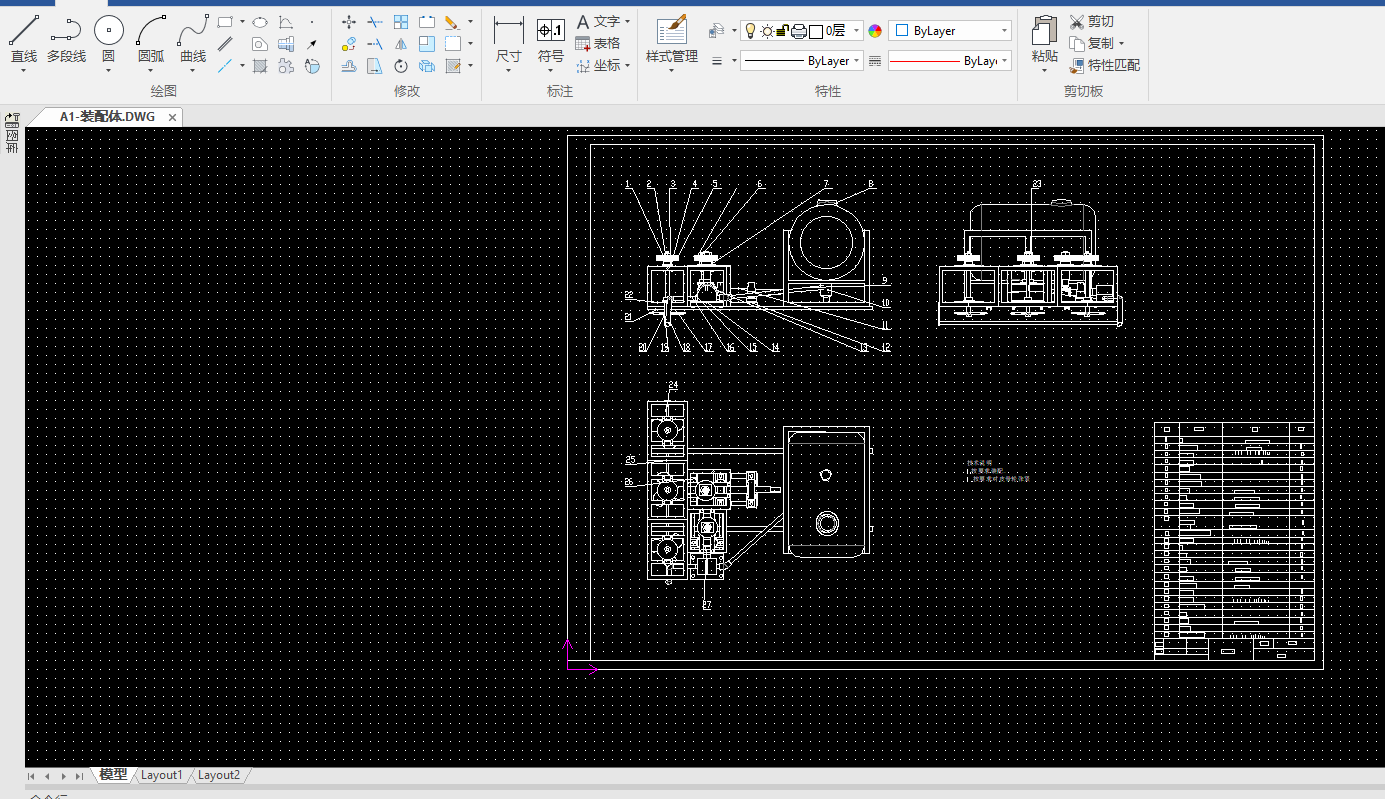

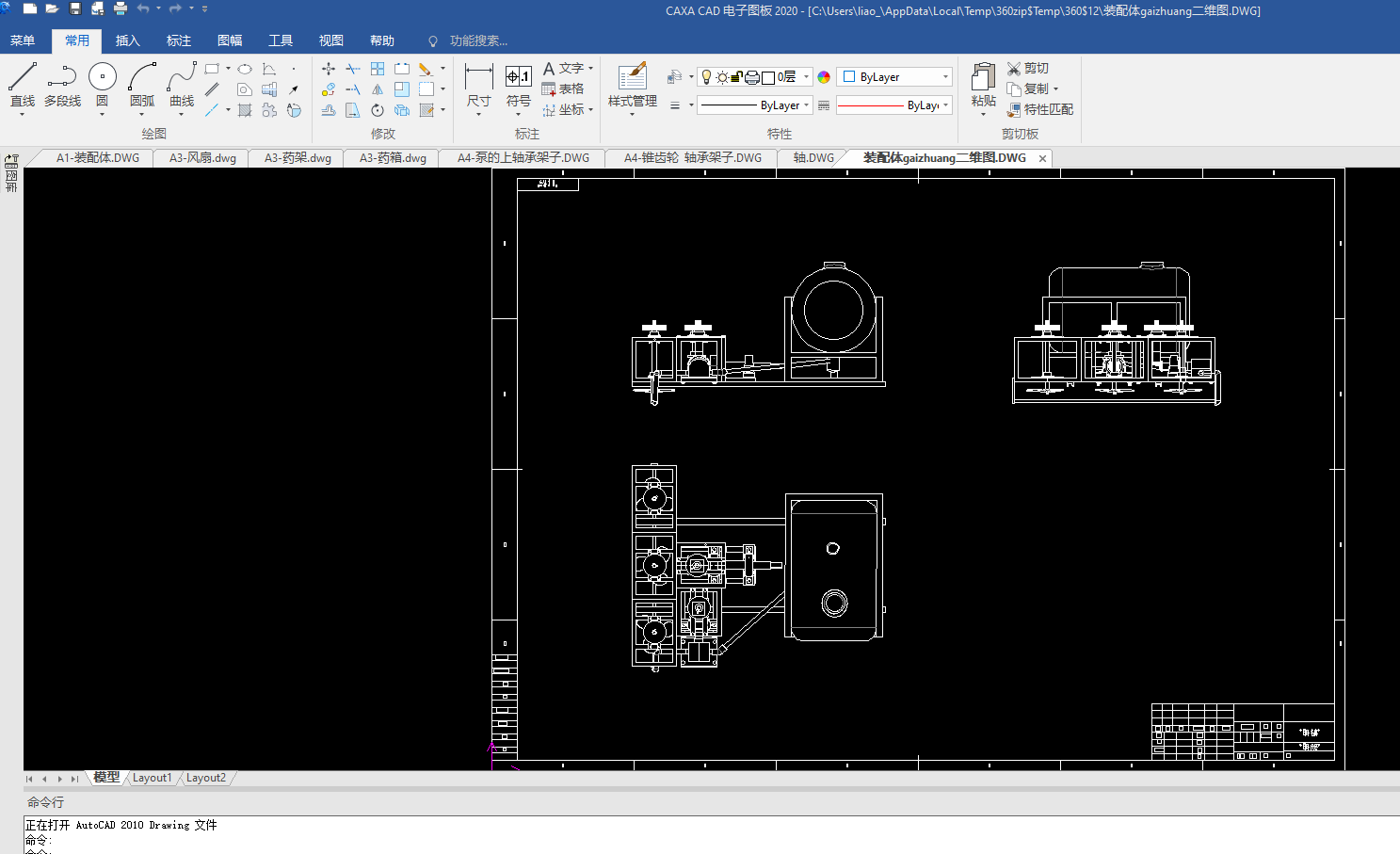

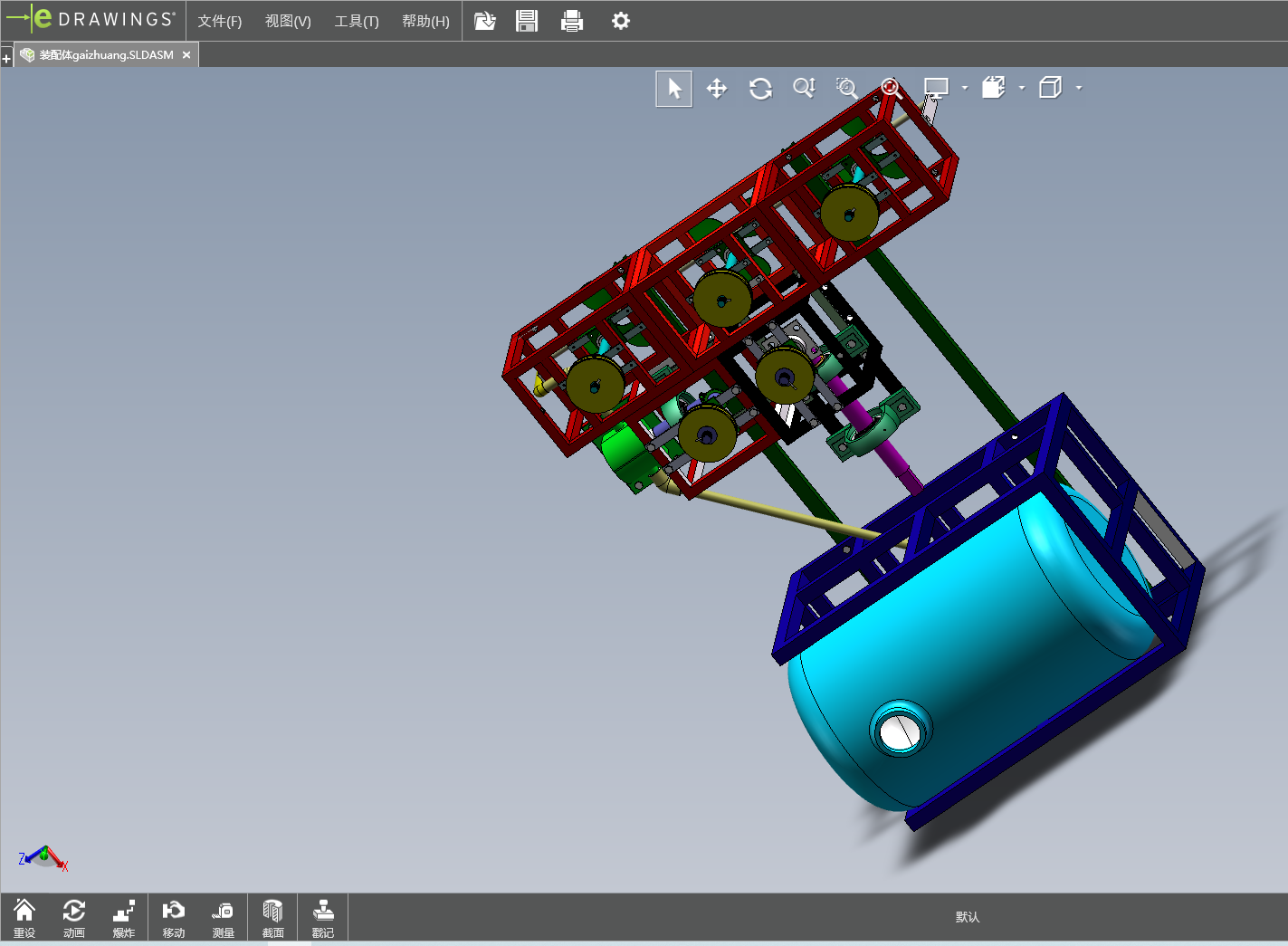

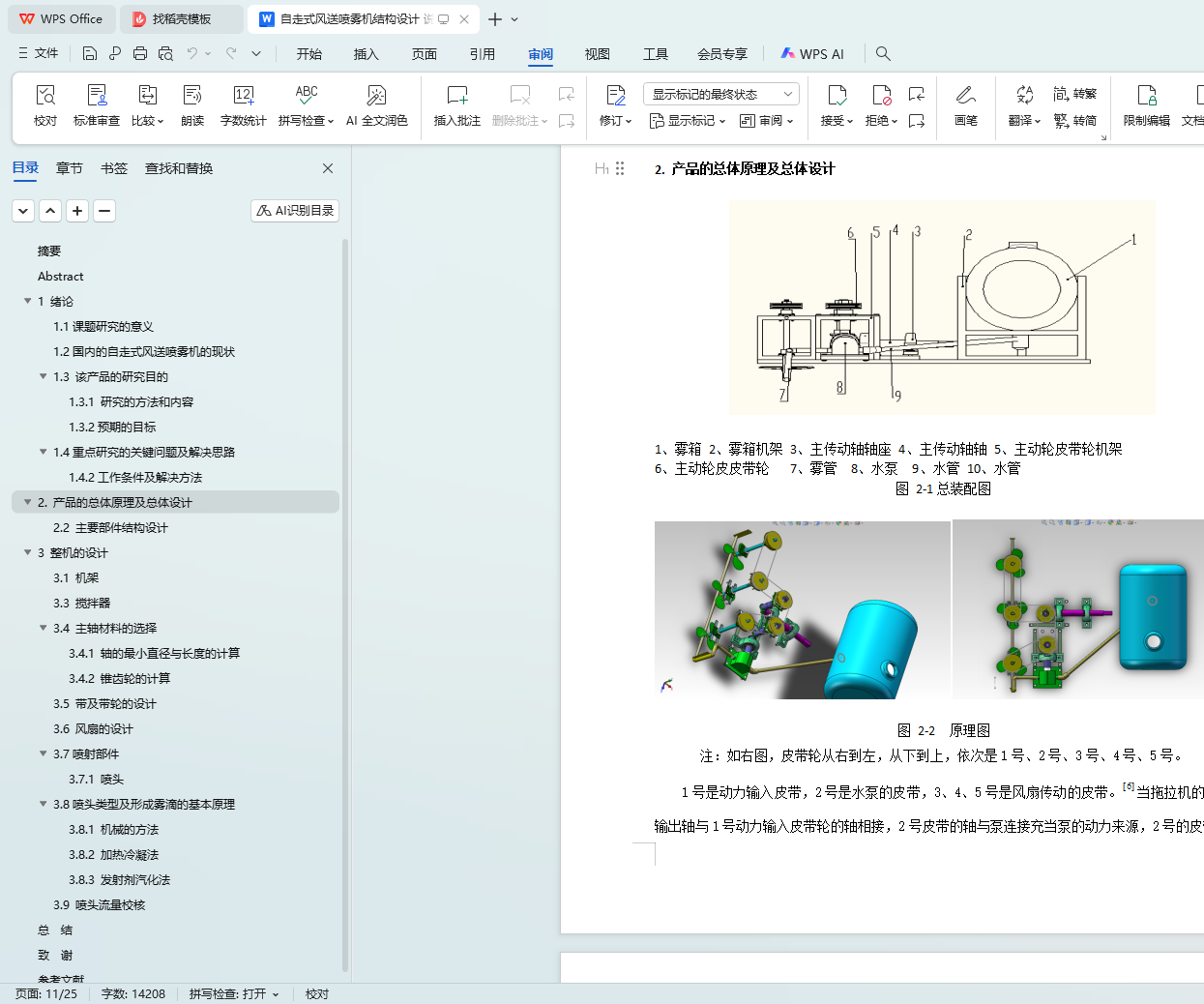

2. 产品的总体原理及总体设计

2.2 主要部件结构设计

3 整机的设计

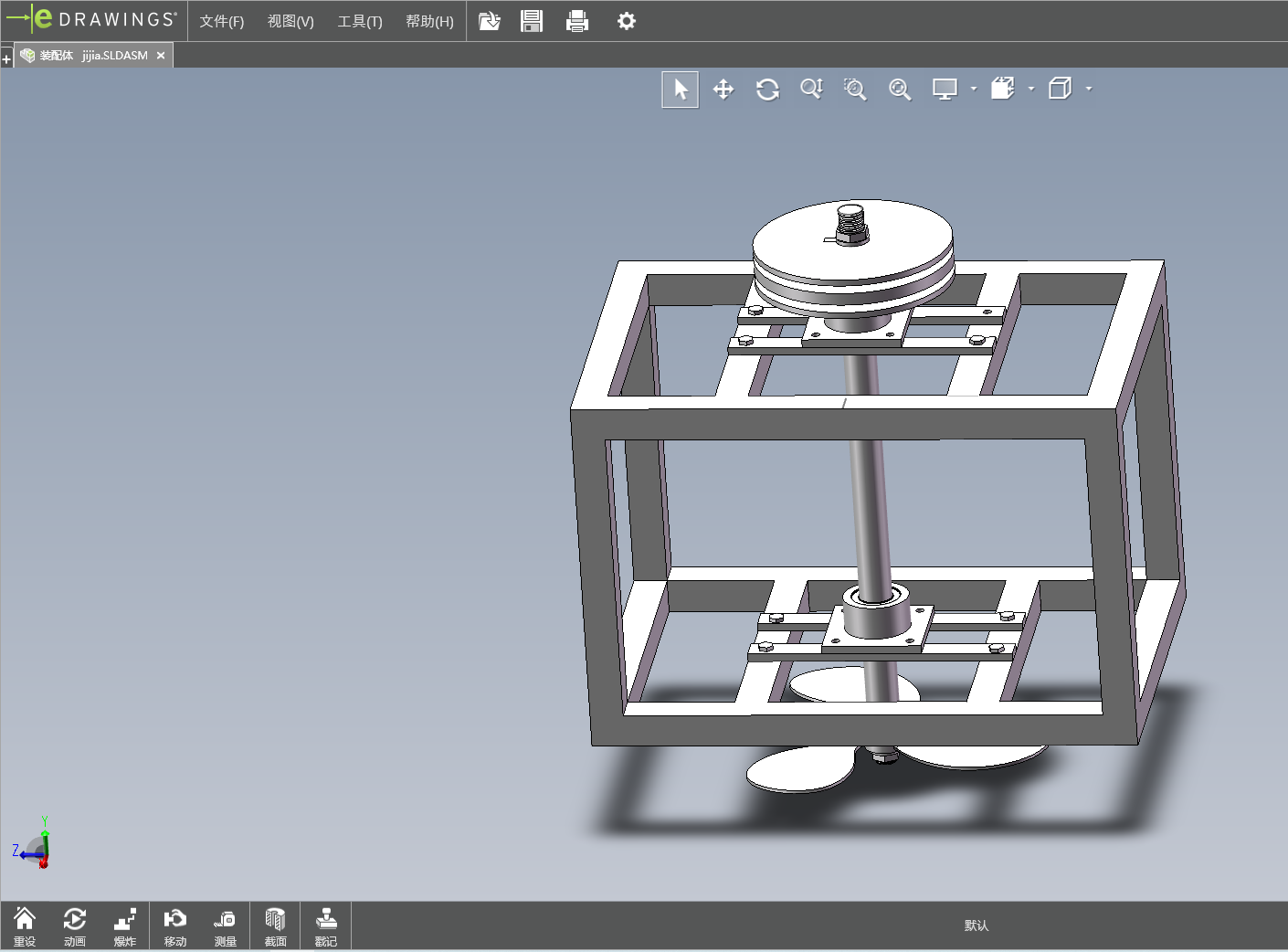

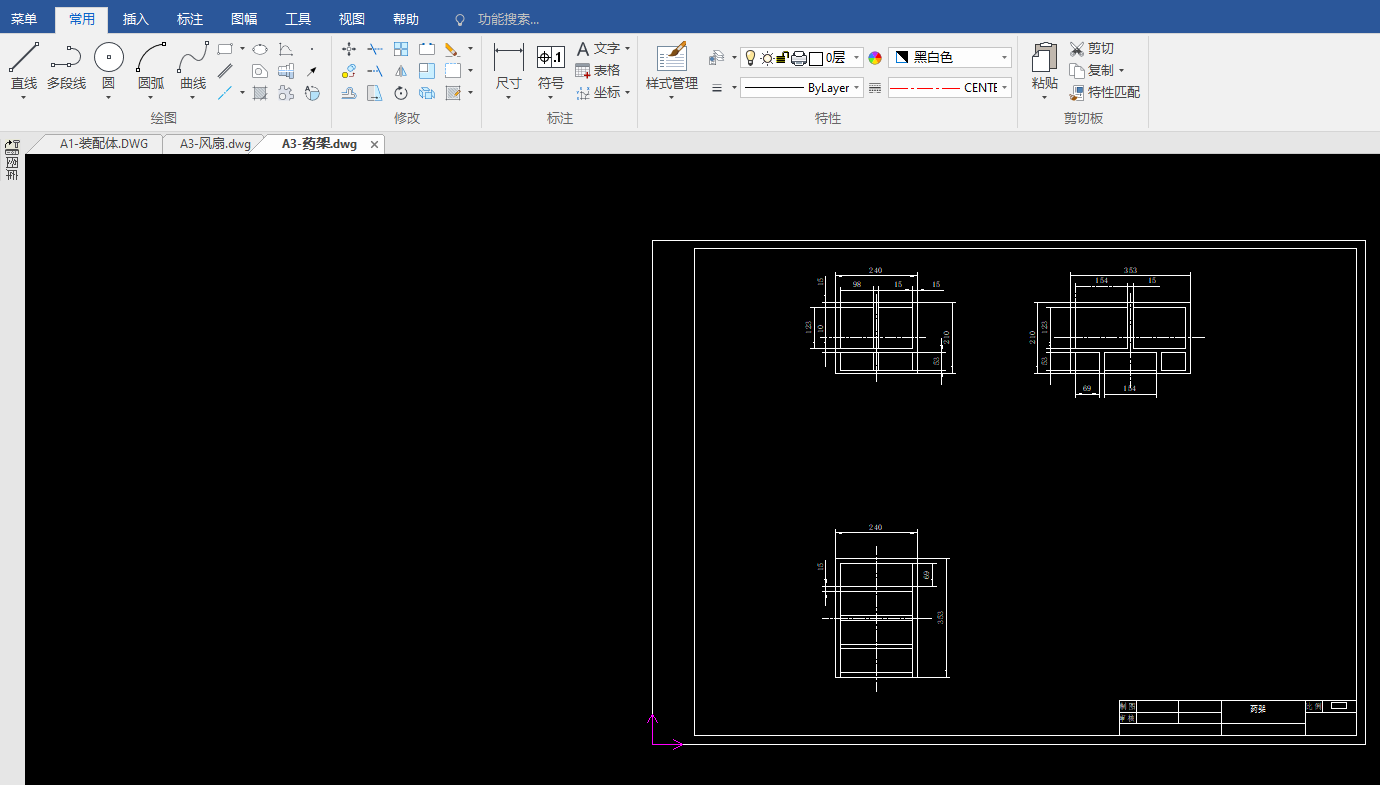

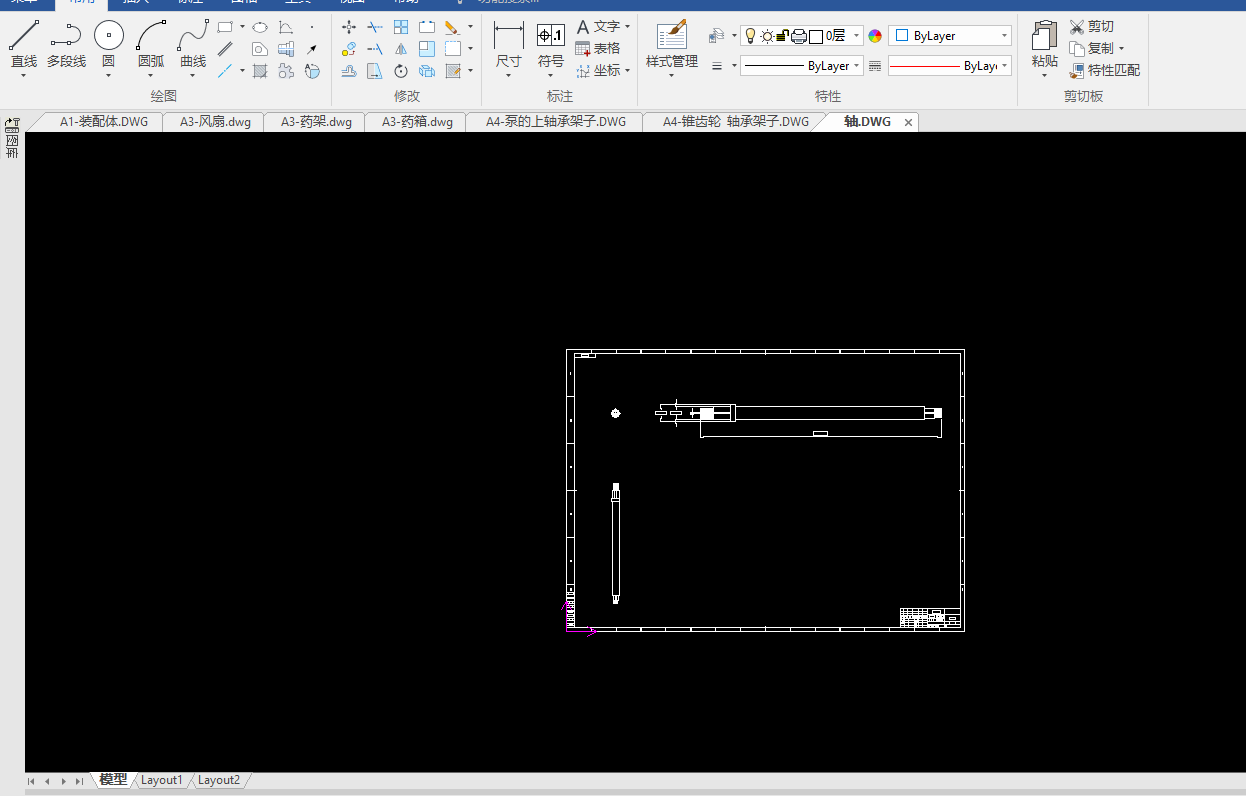

3.1 机架

3.3 搅拌器

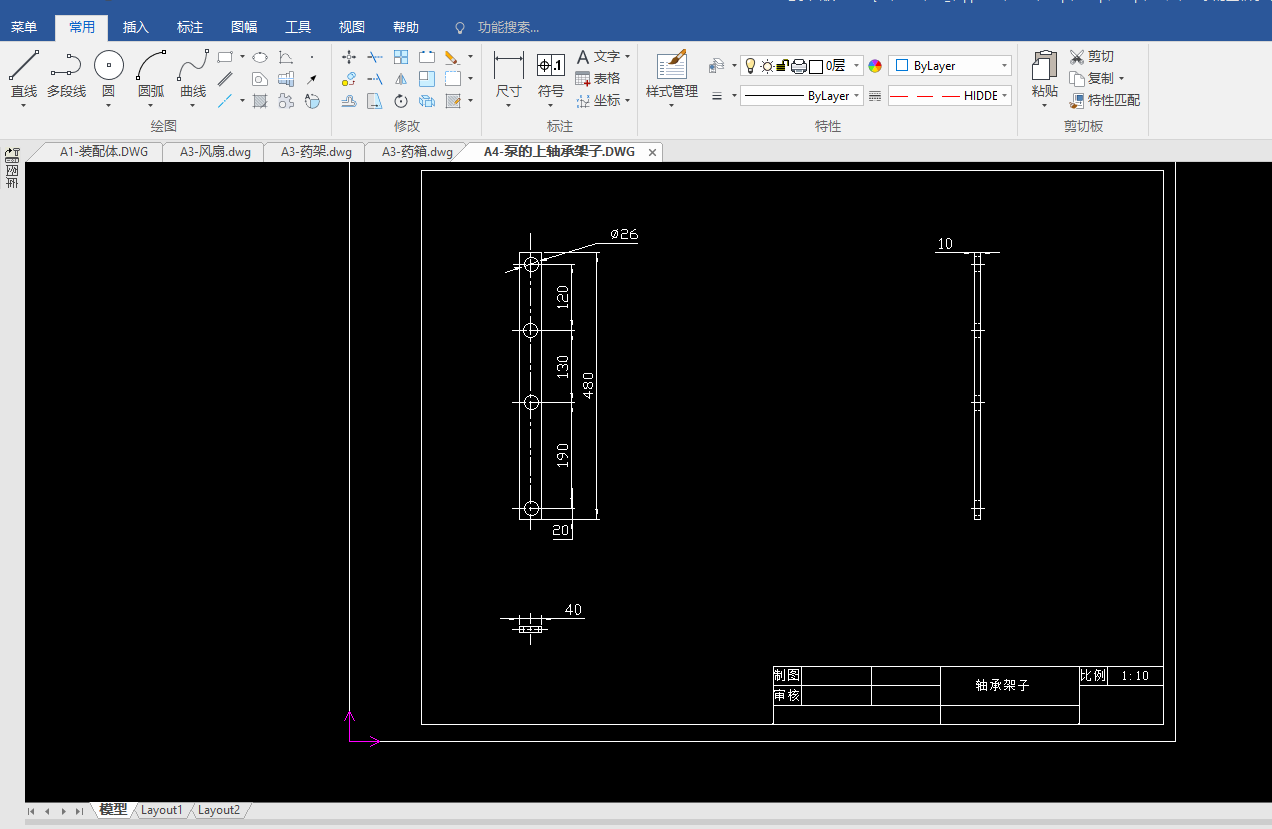

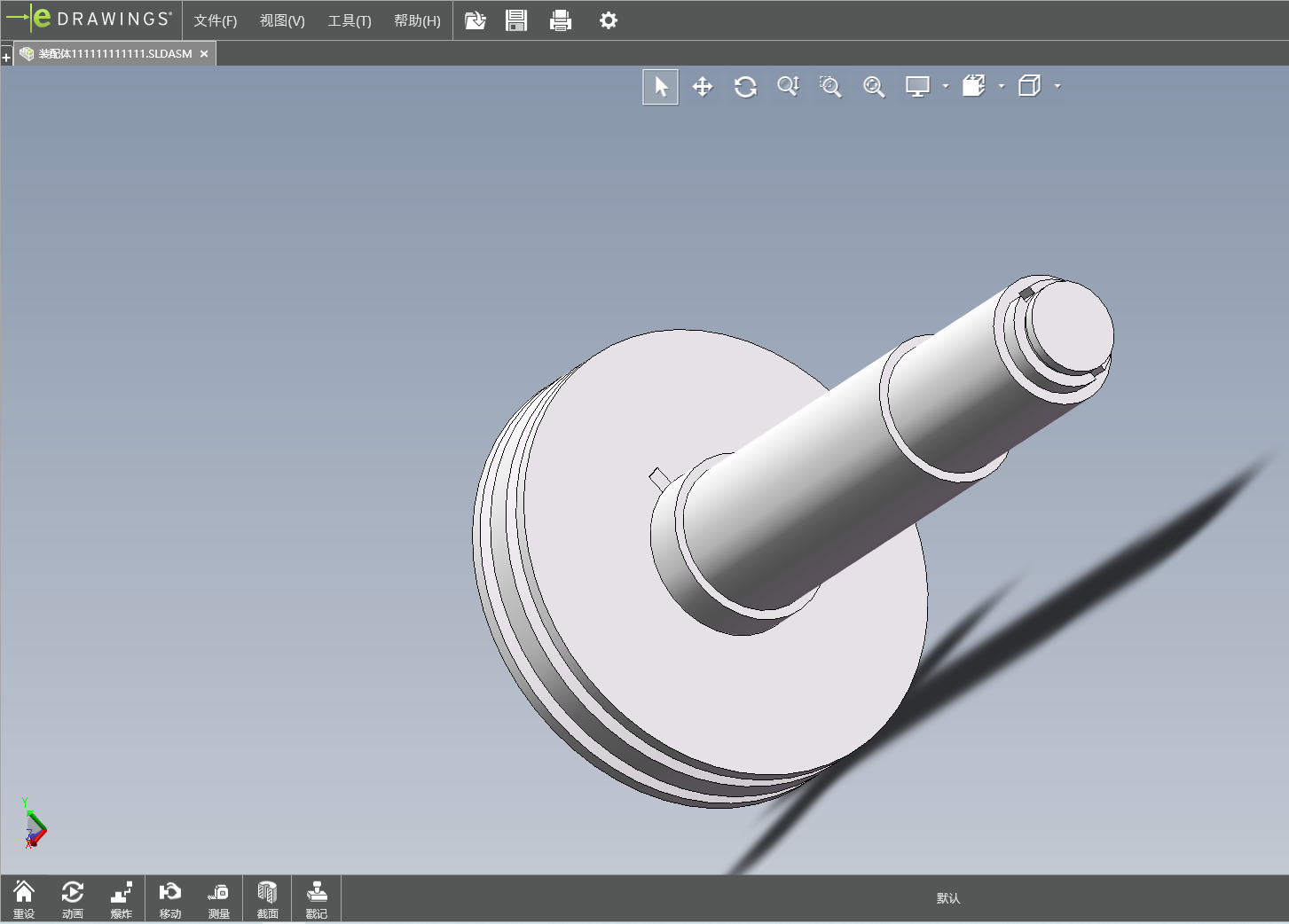

3.4 主轴材料的选择

3.4.1 轴的最小直径与长度的计算

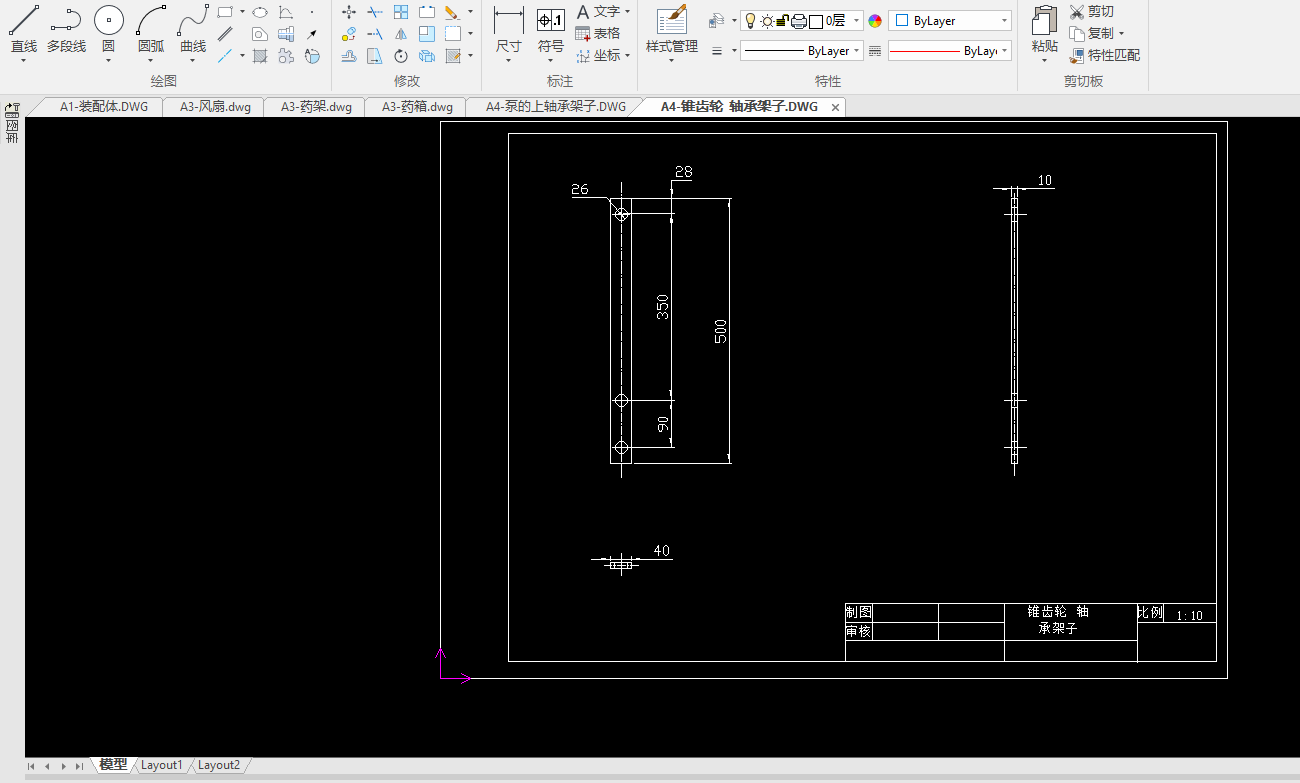

3.4.2 锥齿轮的计算

3.5 带及带轮的设计

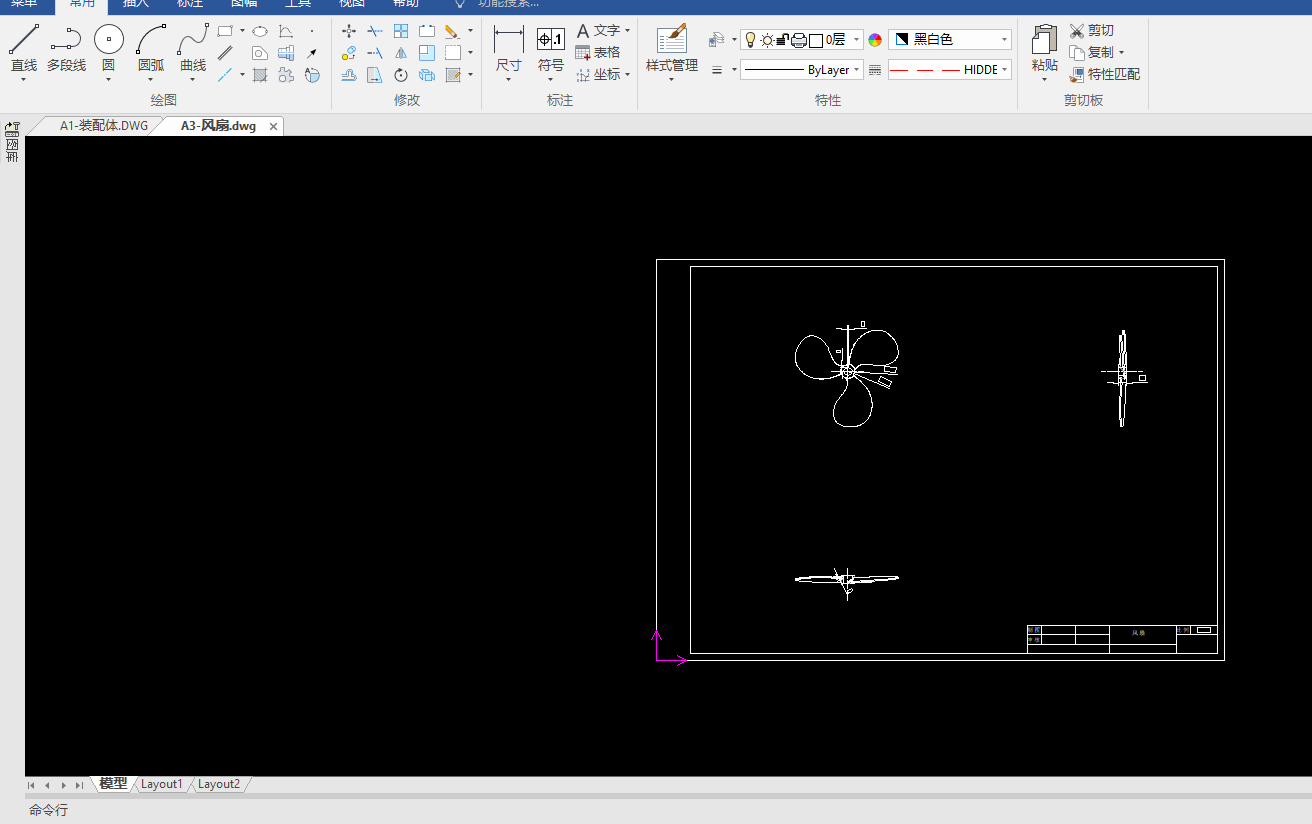

3.6 风扇的设计

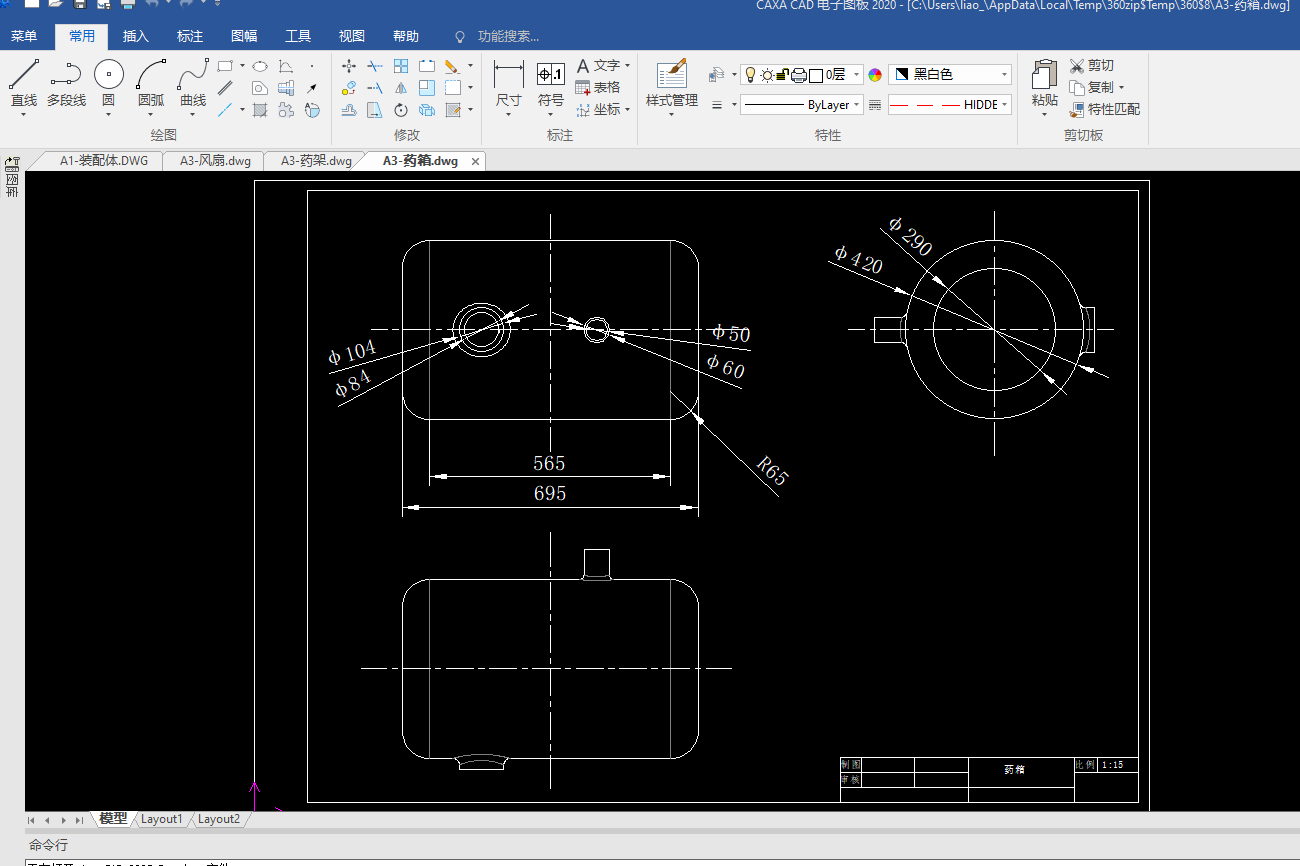

3.7喷射部件

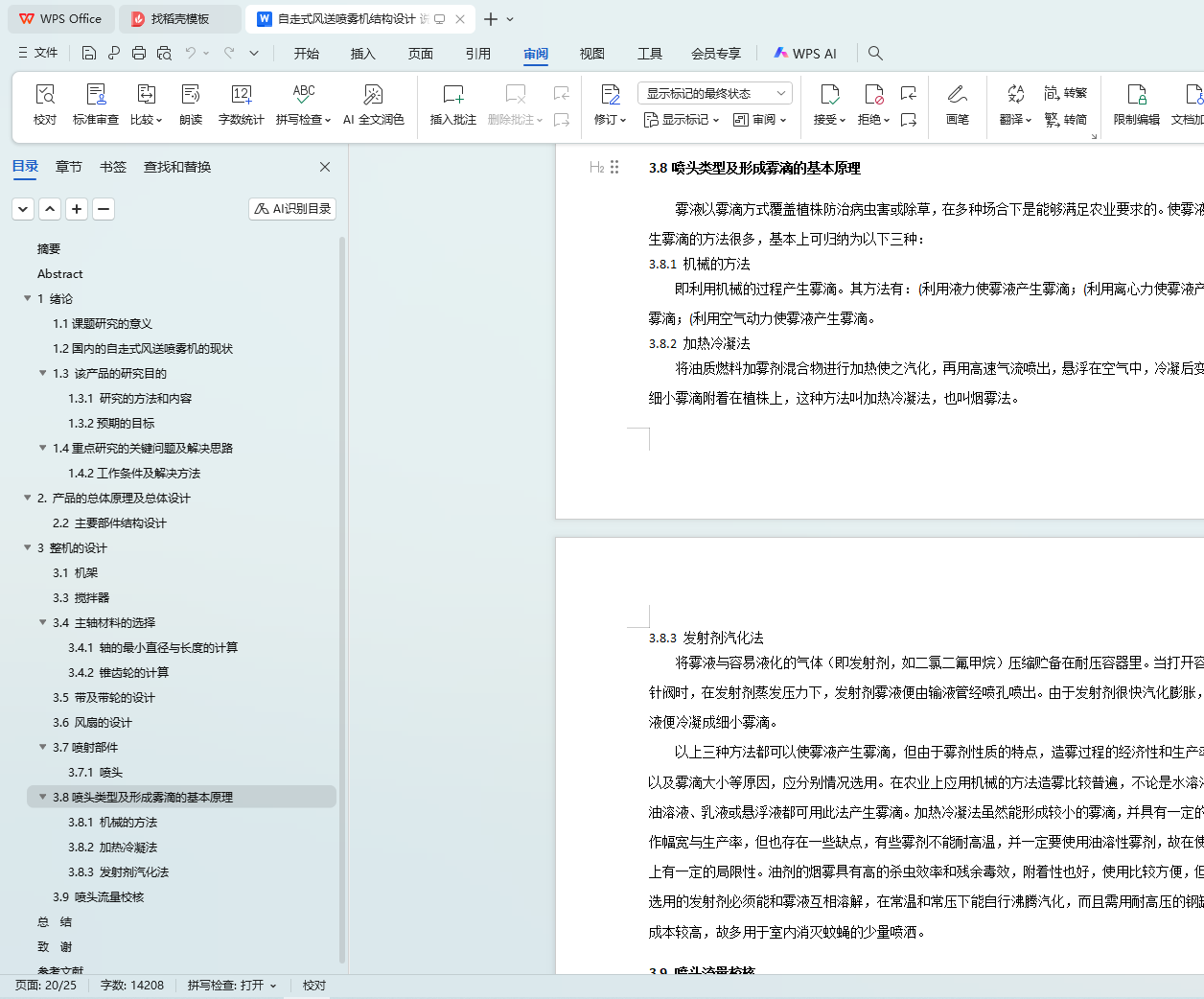

3.7.1 喷头

3.8喷头类型及形成雾滴的基本原理

3.8.1 机械的方法

3.8.2 加热冷凝法

3.8.3 发射剂汽化法

3.9 喷头流量校核

总 结

致 谢

参考文献