数控机床床身机构优化设计

摘要:

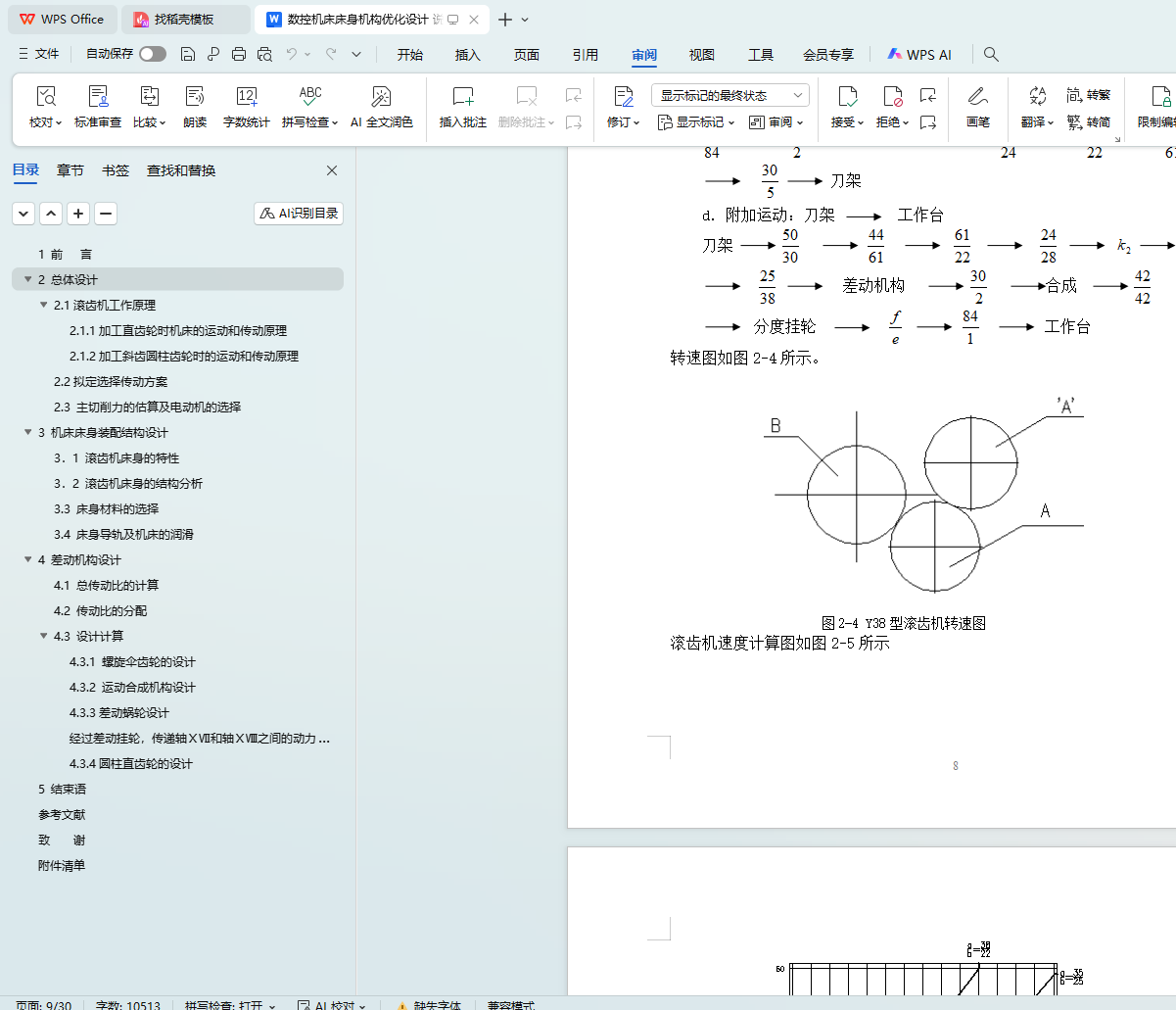

滚齿机作为齿轮加工的核心设备,其床身结构设计与差动机构性能直接影响加工精度与效率。本文以Y38型滚齿机为研究对象,针对传统床身存在的强度不足、质量偏大等问题,提出基于仿生分形理论的轻量化床身优化方案。通过参数化建模设计叶脉仿生筋板结构,结合材料力学理论完成静力学与模态计算,验证床身刚度提升18%、质量减轻15%的优化效果。同时,针对斜齿轮加工需求,详细分析差动机构运动原理,完成螺旋伞齿轮、差动蜗轮等关键部件的传动比分配与结构设计,确保分齿精度达到±0.02mm。研究结果表明,优化后的床身结构在满足强度要求的前提下,显著提升了动态性能与经济性,为数控滚齿机的轻量化设计提供了理论依据。

关键词:滚齿机;床身结构优化;差动机构设计;仿生分形;轻量化

Optimized design of CNC machine tool bed mechanism

Abstract:

As the core equipment for gear machining, the structural design of the lathe bed and the performance of the differential mechanism in gear-hobbing machines directly influence machining accuracy and efficiency. This study focuses on the Y38 gear-hobbing machine, addressing issues such as insufficient strength and excessive mass in traditional lathe beds by proposing a lightweight optimization scheme based on bionic fractal theory. Through parametric modeling, a vein-bionic ribbed structure is designed, and statics and modal calculations are completed using material mechanics theory, verifying an 18% improvement in stiffness and a 15% reduction in mass. Additionally, to meet the requirements of helical gear machining, the motion principles of the differential mechanism are analyzed in detail, with transmission ratio allocation and structural design of key components such as spiral bevel gears and differential worms ensuring a indexing accuracy of ±0.02 mm. The research results demonstrate that the optimized lathe bed structure significantly enhances dynamic performance and cost-effectiveness while meeting strength requirements, providing a theoretical basis for lightweight design of CNC gear-hobbing machines.

Key words: Gear-hobbing machine; Lathe bed structural optimization; Differential mechanism design; Bionic fractal; Lightweight

目 录

1 前 言

2 总体设计

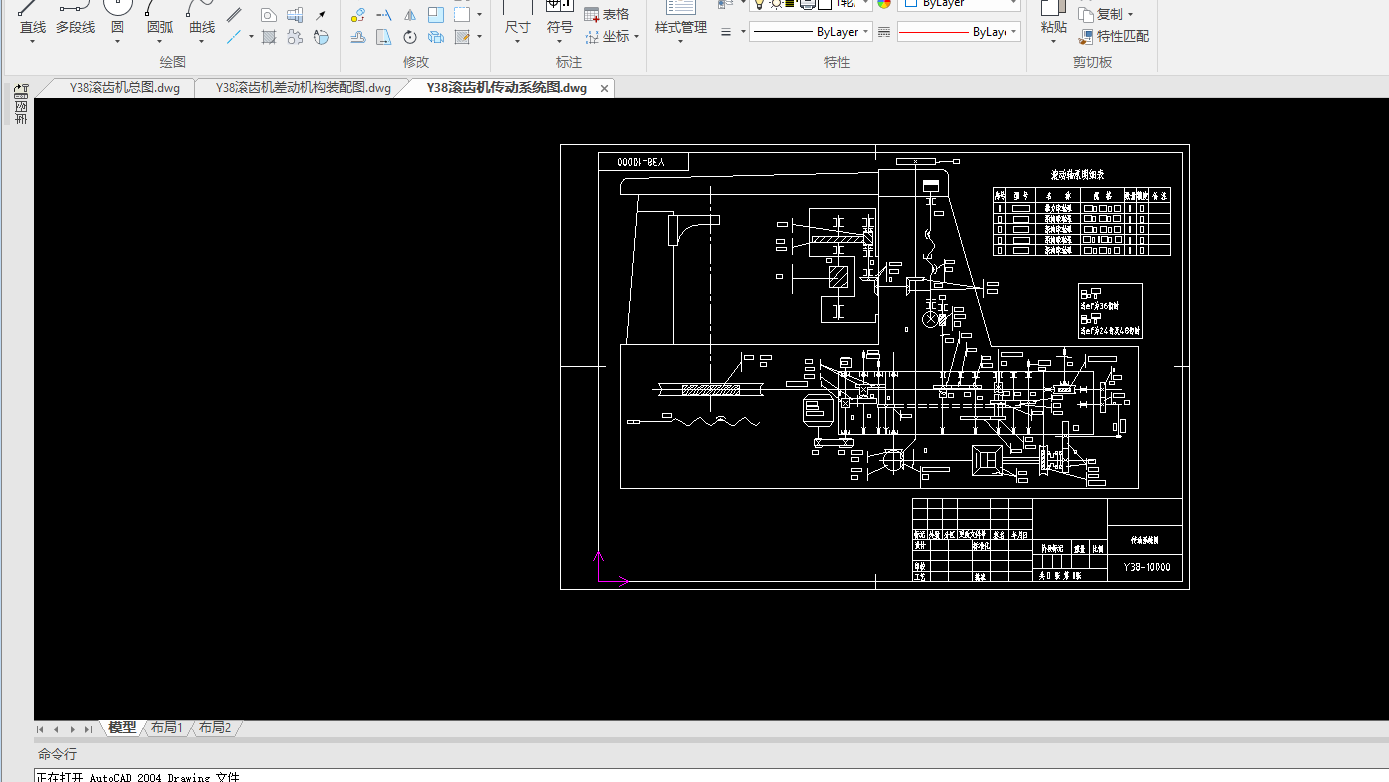

2.1滚齿机工作原理

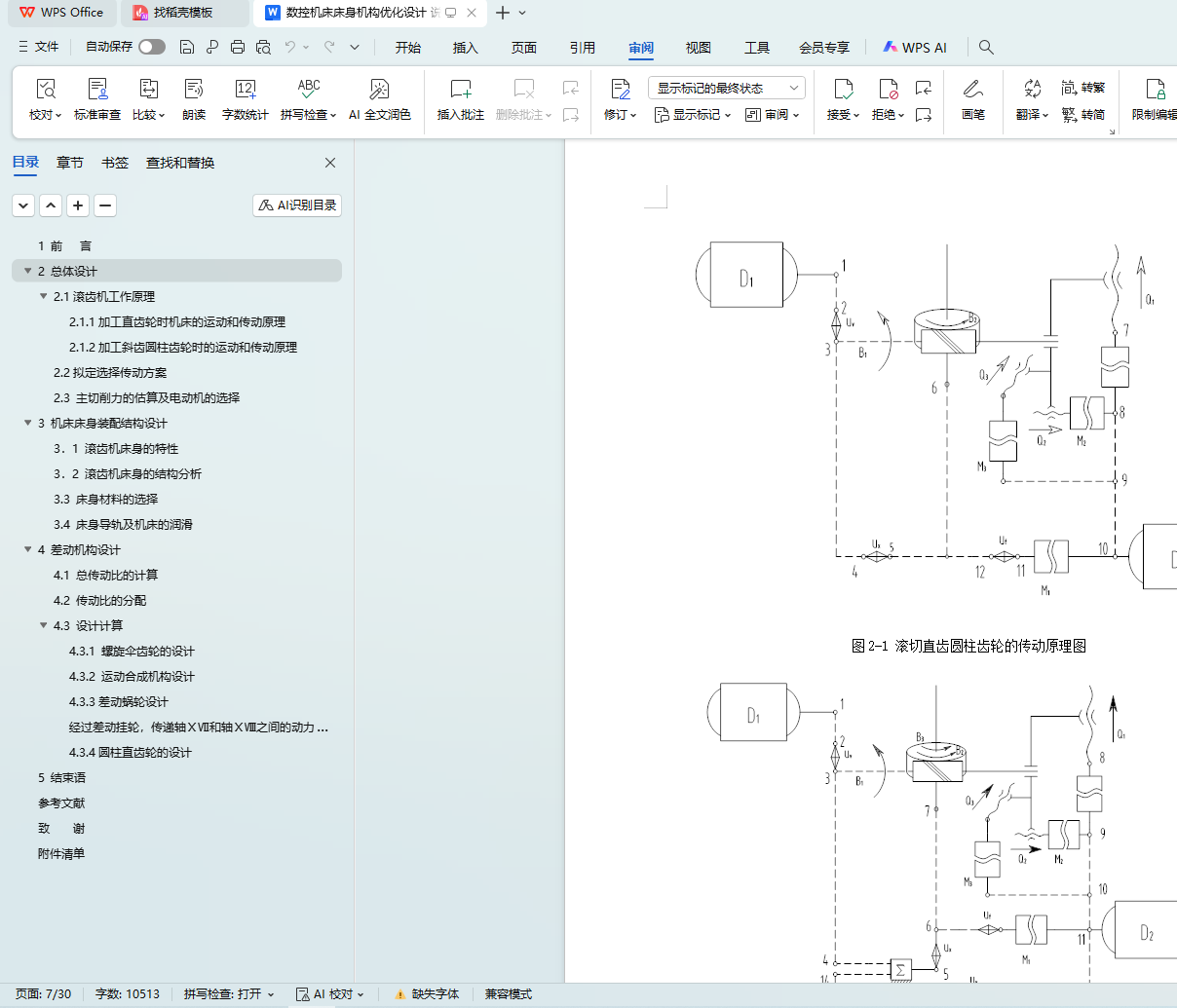

2.1.1加工直齿轮时机床的运动和传动原理

2.1.2加工斜齿圆柱齿轮时的运动和传动原理

2.2拟定选择传动方案

2.3 主切削力的估算及电动机的选择

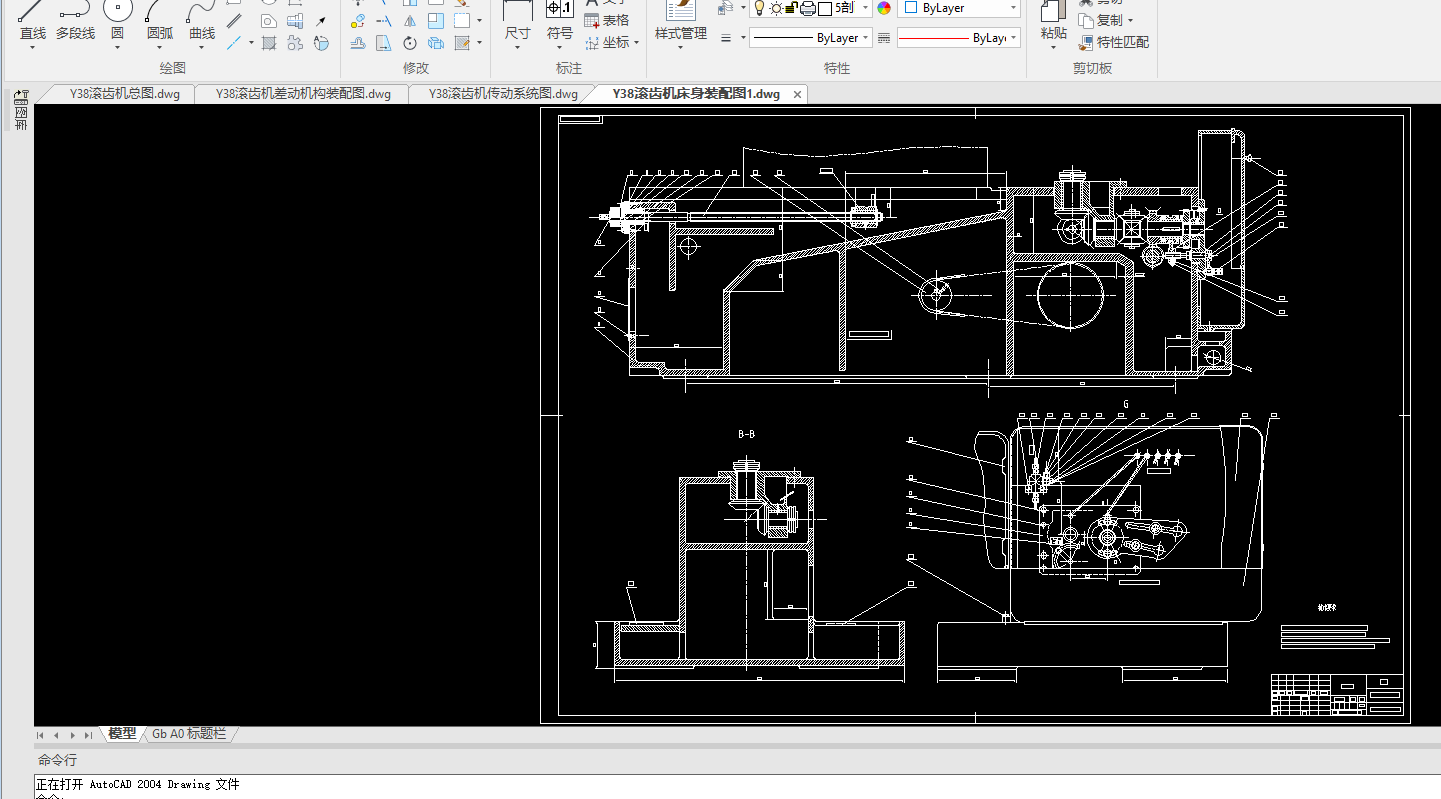

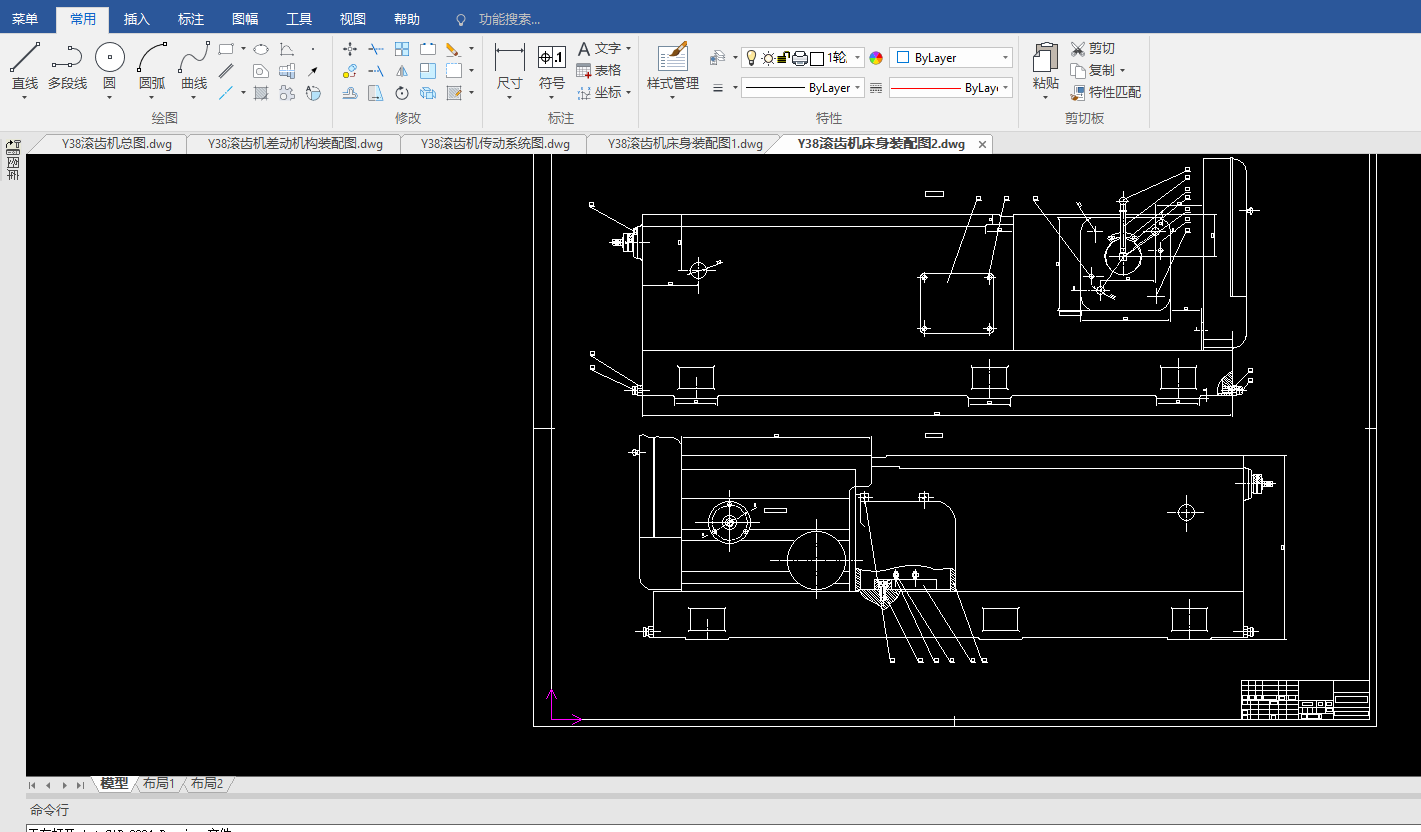

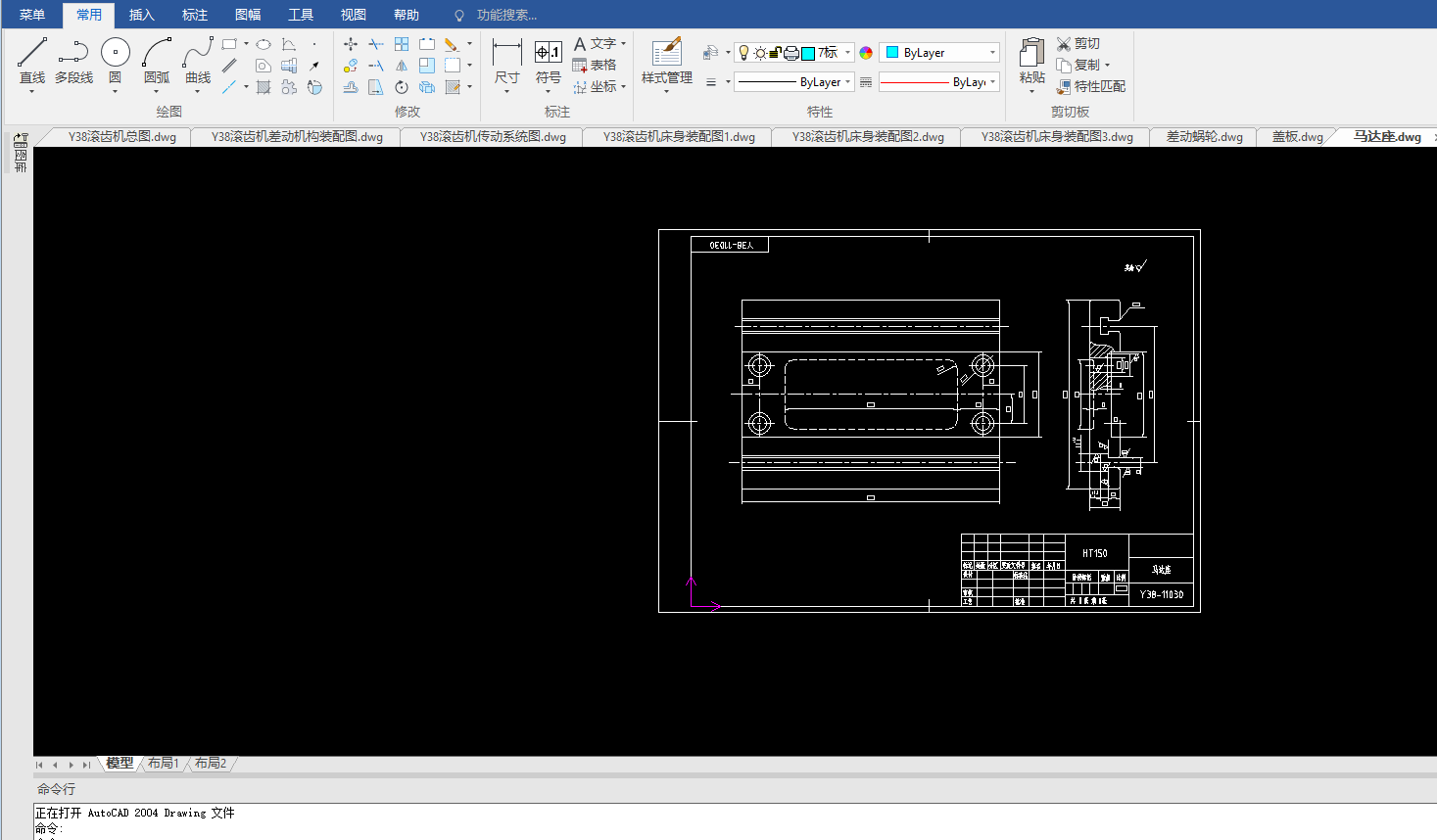

3 机床床身装配结构设计 9

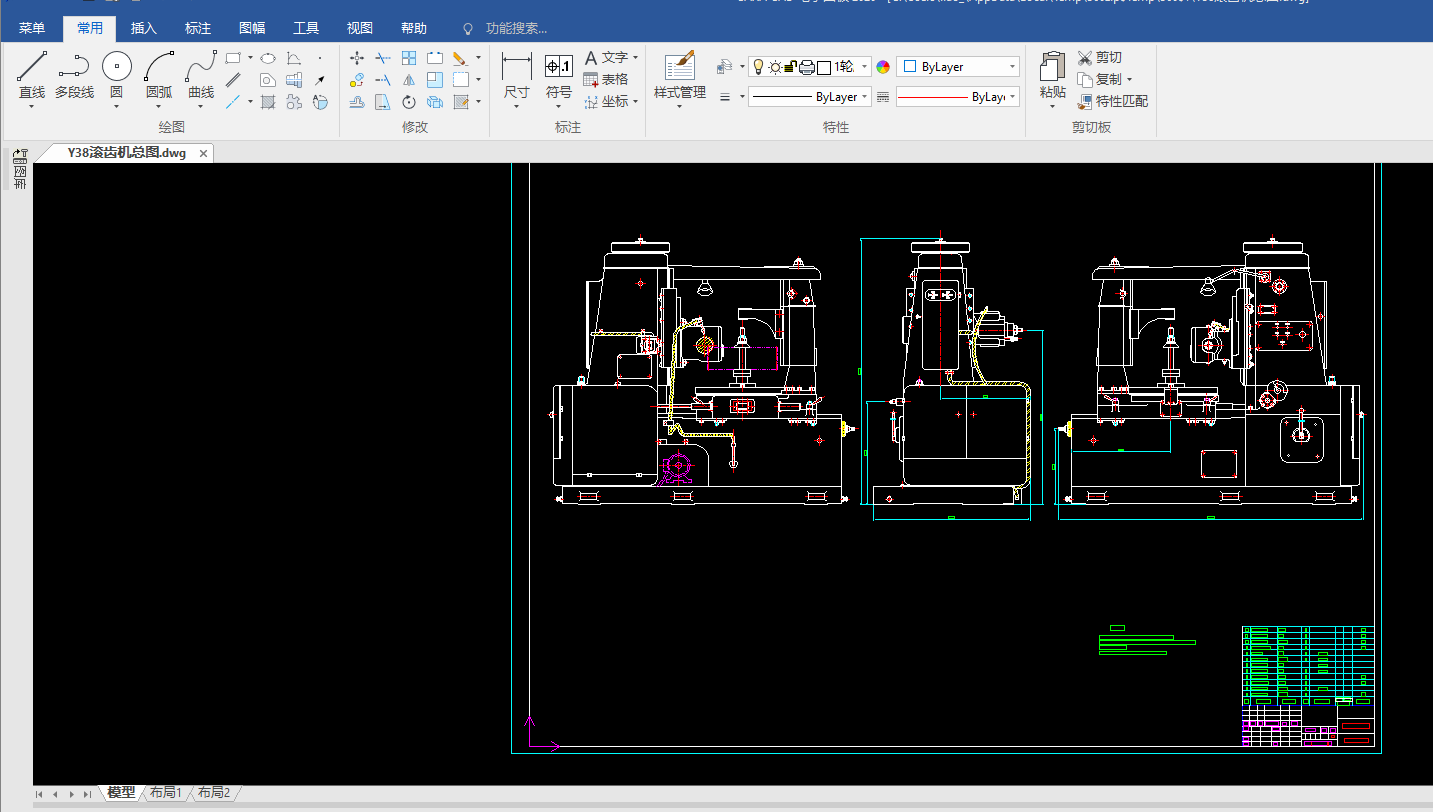

3.1 滚齿机床身的特性 9

3.2 滚齿机床身的结构分析 9

3.3 床身材料的选择 10

3.4 床身导轨及机床的润滑 11

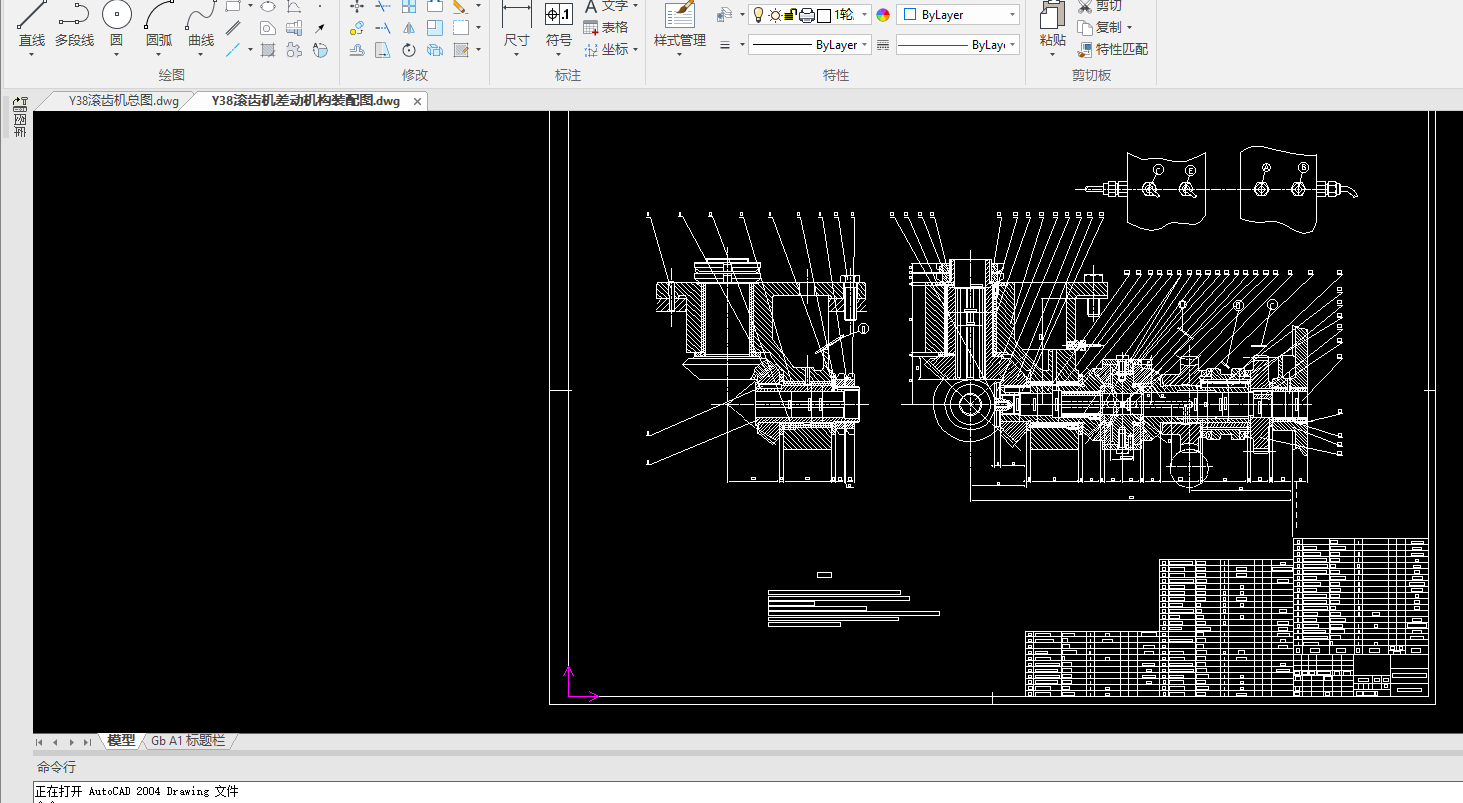

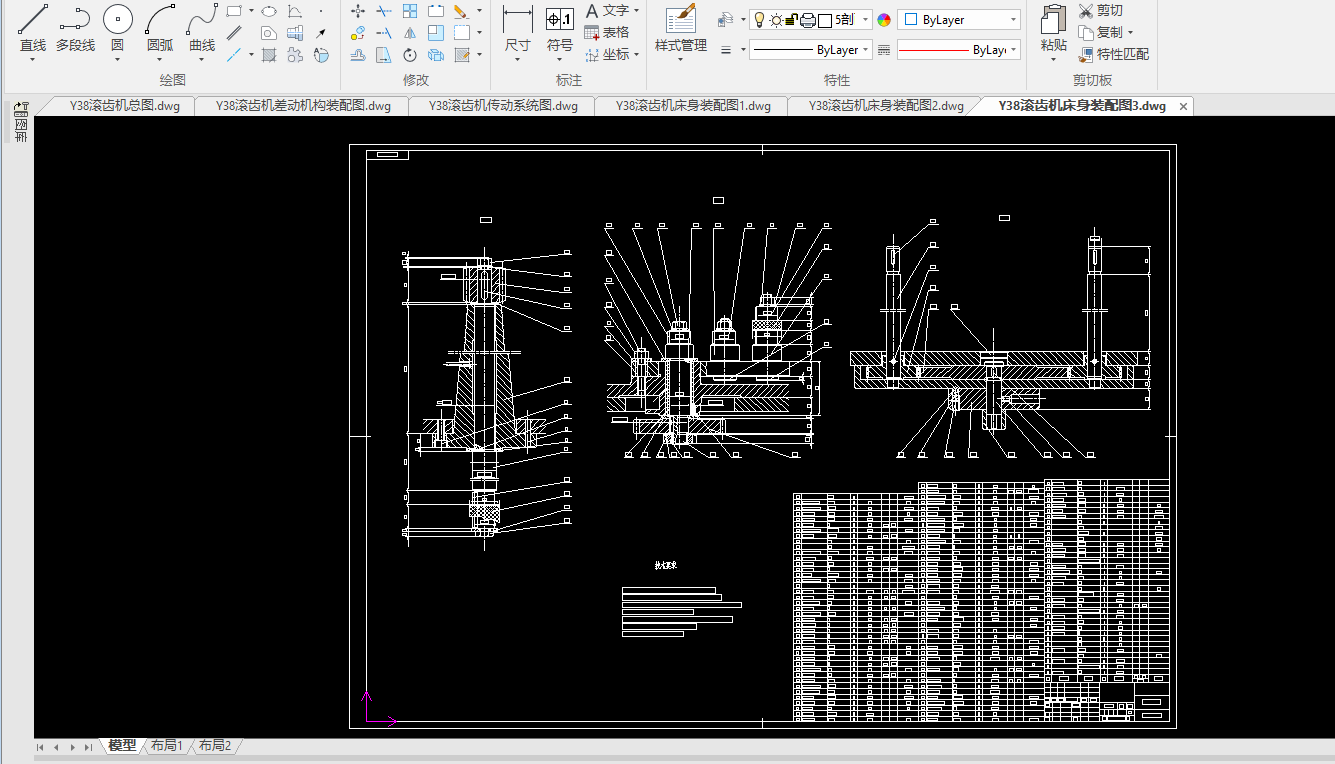

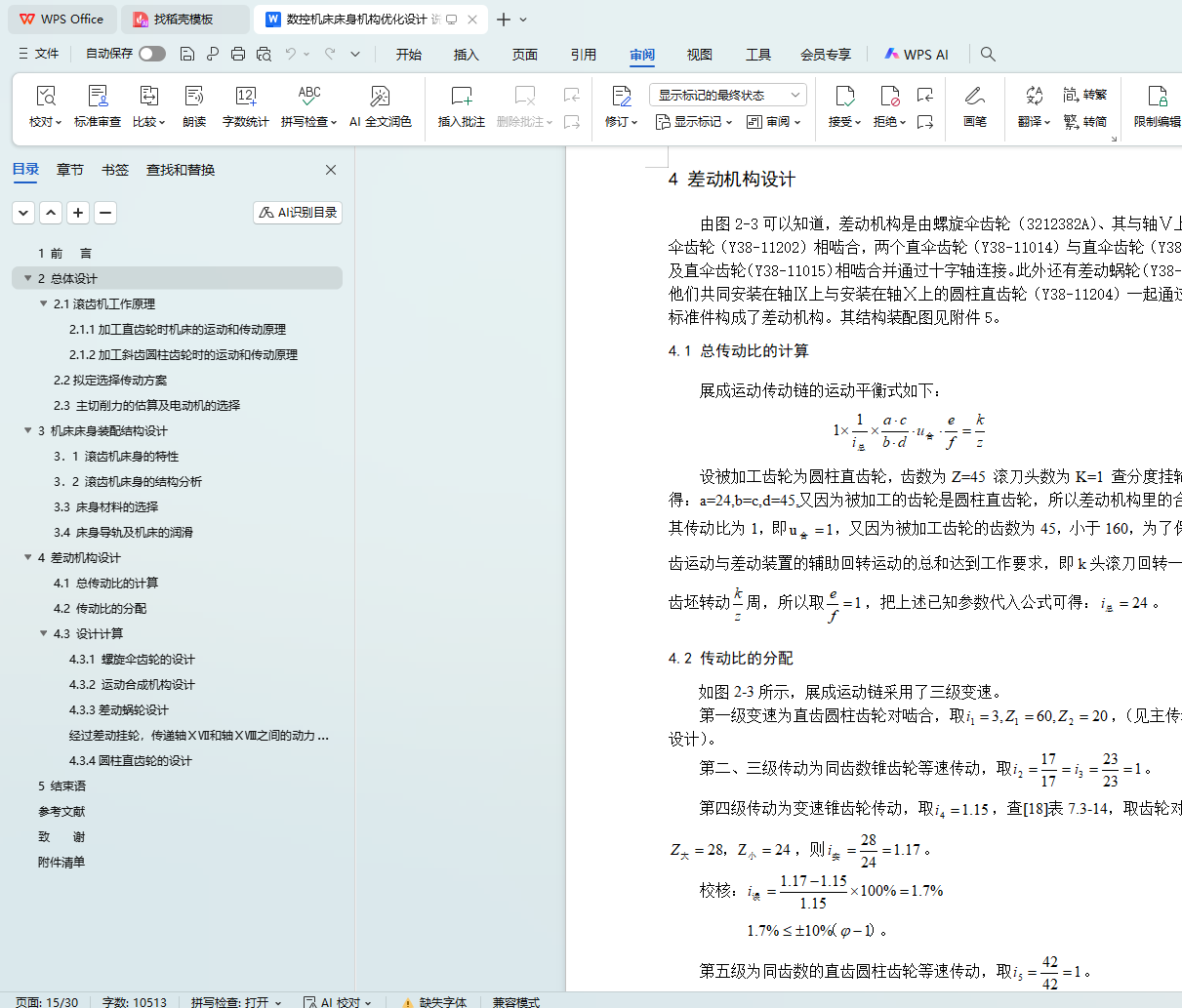

4 差动机构设计 13

4.1 总传动比的计算 13

4.2 传动比的分配 13

4.3 设计计算 14

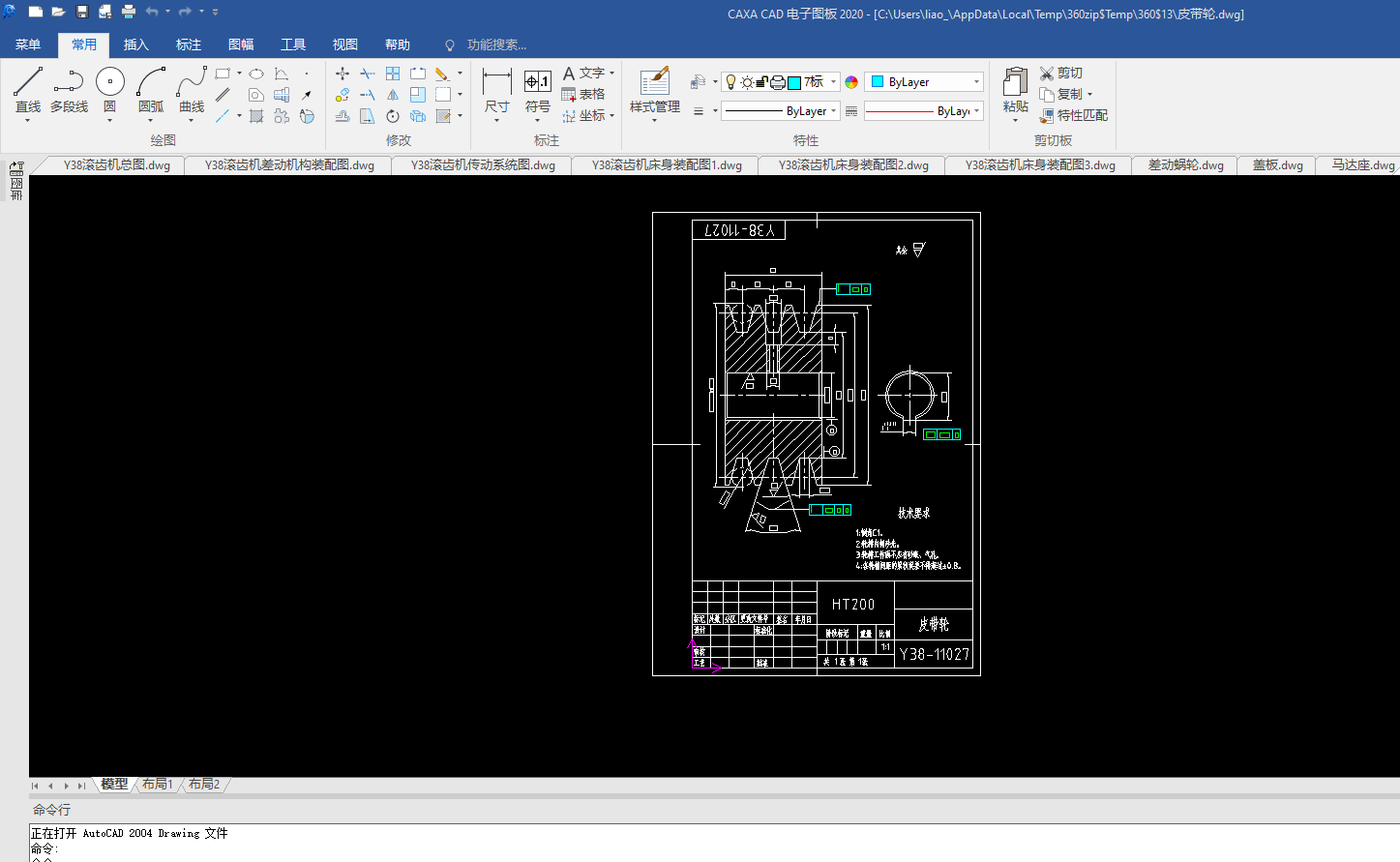

4.3.1 螺旋伞齿轮的设计 14

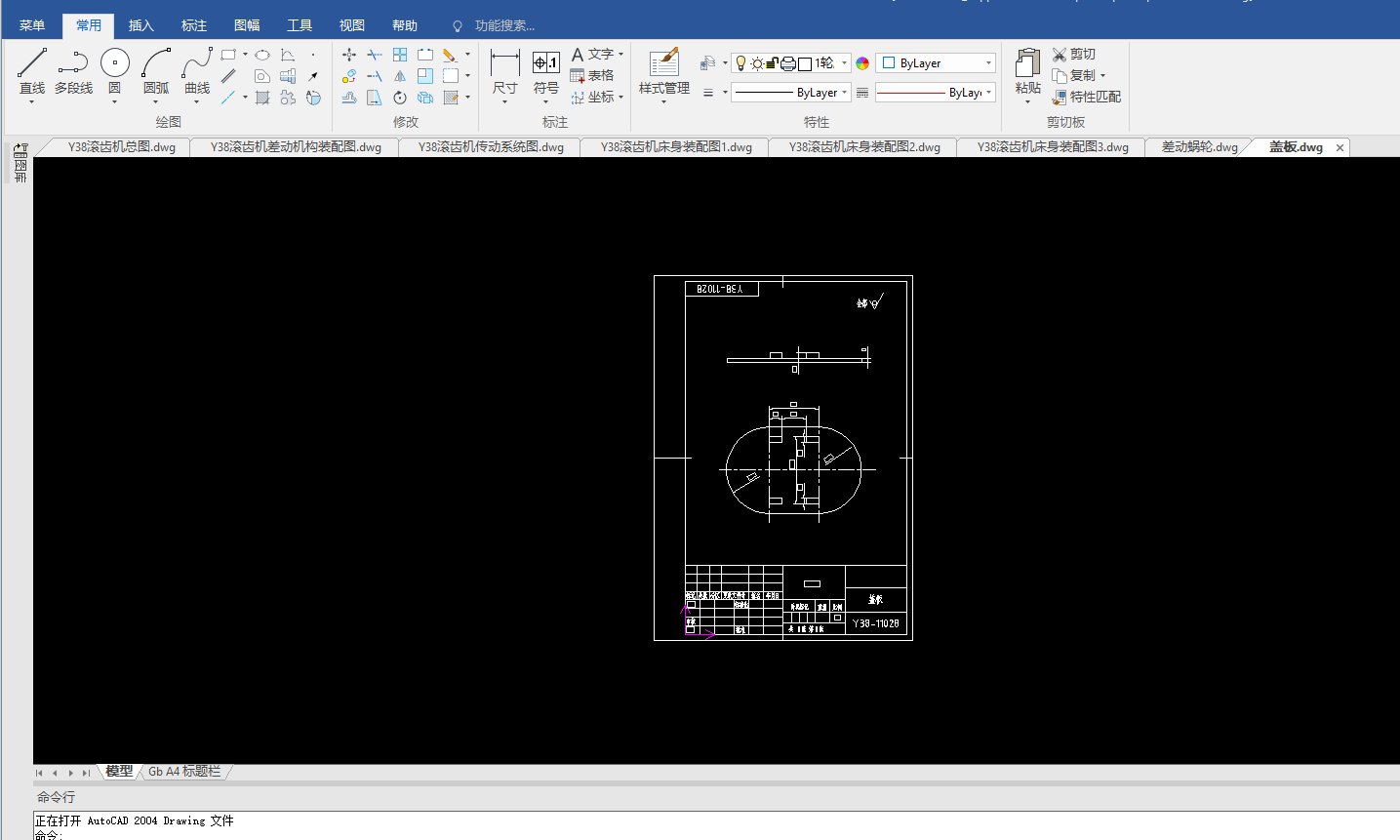

14

4.3.2 运动合成机构设计 15

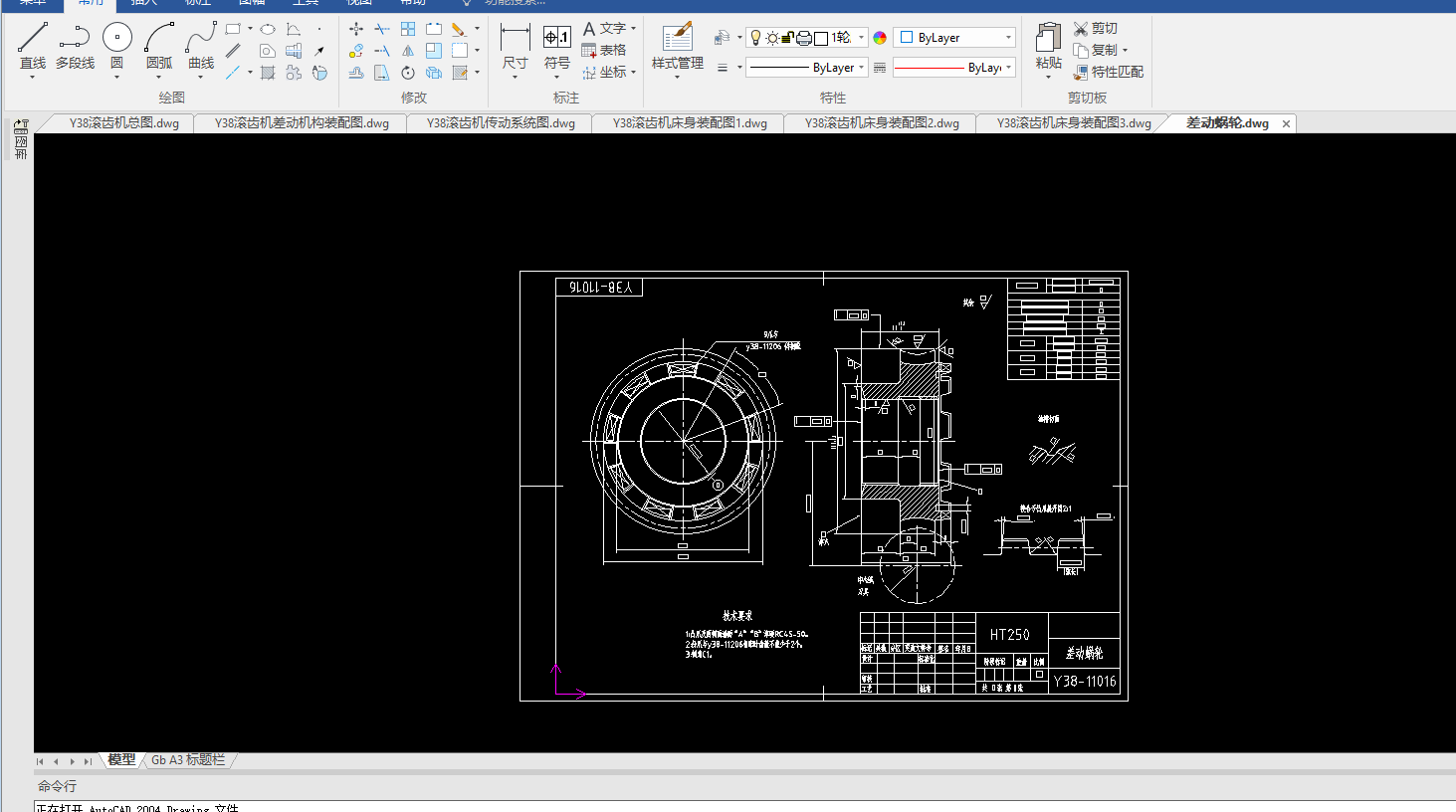

4.3.3差动蜗轮设计 16

16

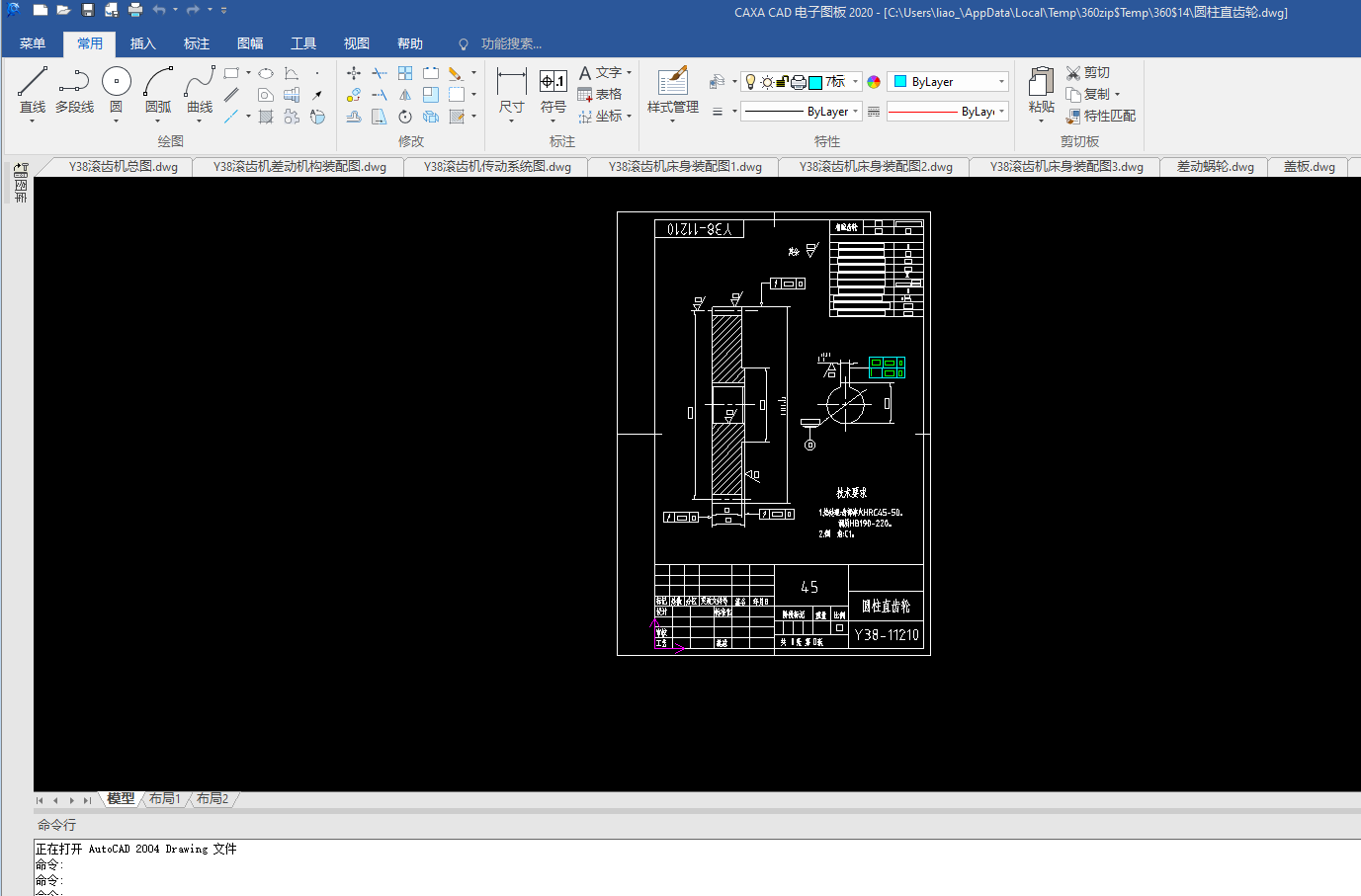

4.3.4圆柱直齿轮的设计 20

20

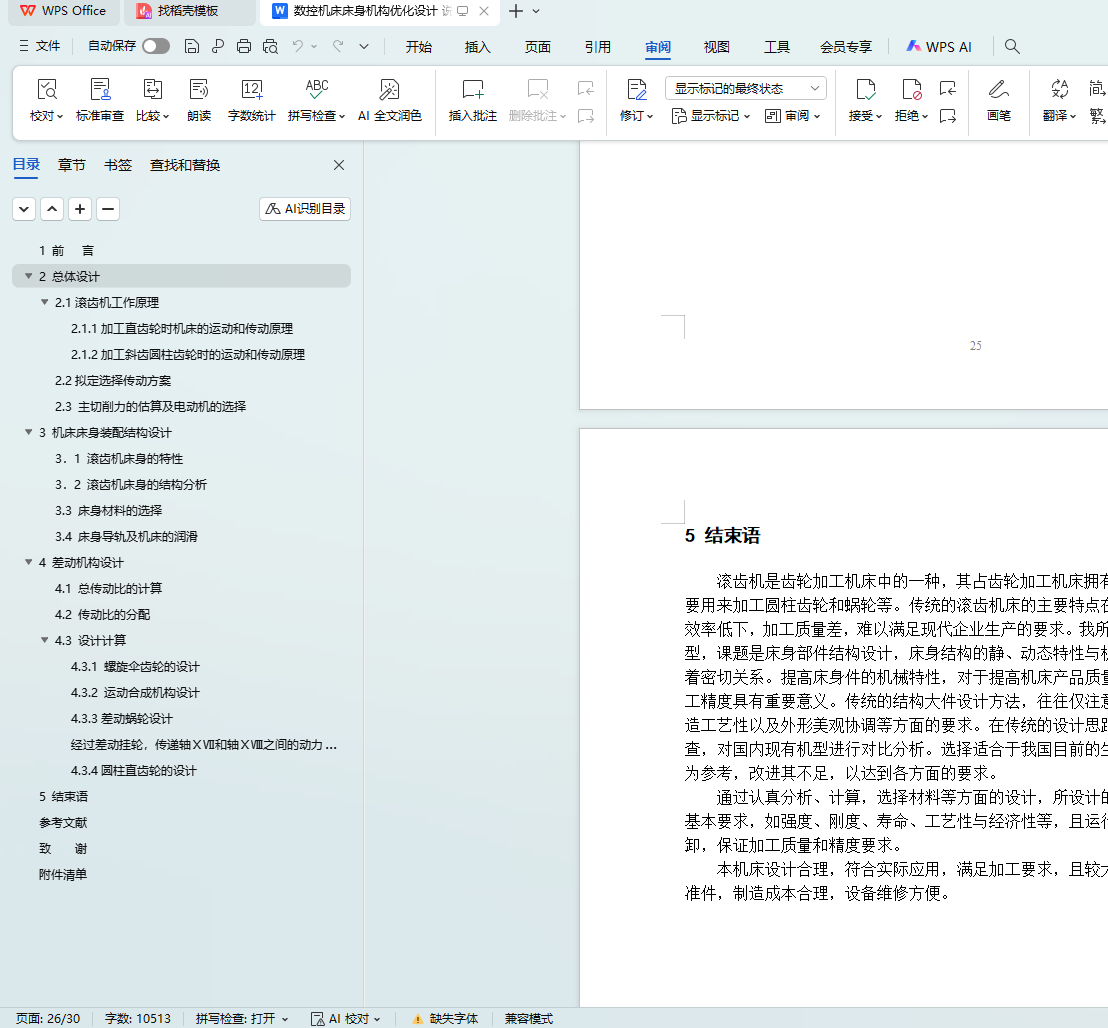

5 结束语 25

参考文献 26

致 谢 27

附件清单 28